Content Menu

● Understanding T-Slot Aluminum Extrusions

● Advantages of T-Slot Aluminum Extrusions

>> Lightweight Design

>> Modular Construction

>> Flexibility and Customization

● Applications of T-Slot Aluminum Extrusions

>> Industrial Automation

>> Mechanical Frameworks

>> Transportation and Logistics

● Assembly and Design Tips

>> Effective Assembly Techniques

>> Design Considerations

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum extrusion frames in construction?

>> 2. How do T-slot aluminum extrusions compare to traditional framing materials?

>> 3. Can T-slot aluminum extrusions be used for outdoor applications?

>> 4. What tools are needed to assemble T-slot aluminum extrusions?

>> 5. Are there any limitations to using T-slot aluminum extrusions?

Understanding T-Slot Aluminum Extrusions

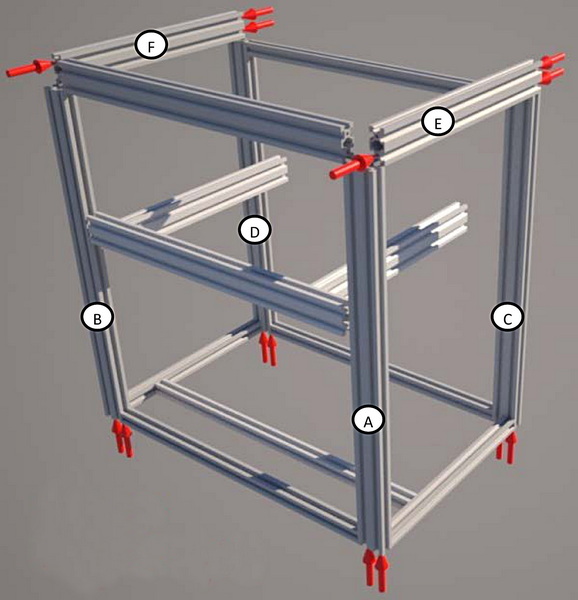

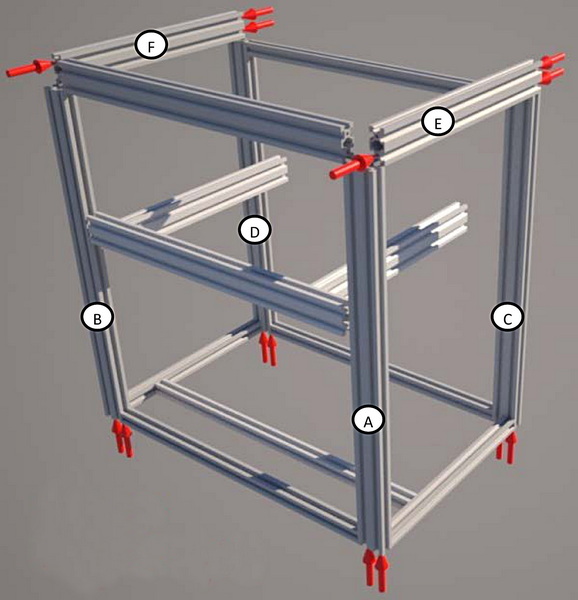

T-slot aluminum extrusions are structural components that feature a T-shaped slot along their length. This design allows for easy attachment of other components, making them ideal for creating frames, supports, and various structures. The T-slot design enables users to connect multiple pieces without the need for complex tools or extensive fabrication processes.

The primary material used in these extrusions is aluminum, known for its lightweight yet strong properties. This combination of strength and weight makes T-slot aluminum extrusions a popular choice in various industries, including manufacturing, automation, and construction.

Advantages of T-Slot Aluminum Extrusions

Lightweight Design

One of the most significant advantages of T-slot aluminum extrusions is their lightweight nature. Aluminum has a high strength-to-weight ratio, meaning it can support substantial loads while remaining easy to handle and transport. This characteristic is particularly beneficial in applications where weight is a critical factor, such as in aerospace or automotive industries.

The lightweight design of aluminum extrusion frames also contributes to reduced shipping costs and easier installation. Projects that require frequent relocation or modification can benefit immensely from the ease of handling these materials.

Modular Construction

T-slot aluminum extrusions are inherently modular, allowing for quick and efficient assembly of structures. This modularity means that components can be easily added, removed, or reconfigured as project requirements change. This flexibility is invaluable in dynamic environments where adaptability is essential.

For instance, in manufacturing settings, production lines can be adjusted to accommodate new machinery or processes without the need for extensive renovations. The ability to modify structures quickly can lead to significant time and cost savings.

Flexibility and Customization

Another key benefit of T-slot aluminum extrusions is their flexibility and customization options. With a wide range of profiles and accessories available, users can design and build structures tailored to their specific needs. Whether creating a simple frame or a complex assembly, the versatility of T-slot extrusions allows for endless possibilities.

Custom aluminum frames can be designed to fit unique specifications, ensuring that every project meets its intended purpose. This level of customization is particularly advantageous in industries such as robotics, where precise measurements and configurations are crucial.

Applications of T-Slot Aluminum Extrusions

Industrial Automation

T-slot aluminum extrusions are widely used in industrial automation applications. They serve as the backbone for robotic systems, conveyor belts, and assembly lines. The ability to create sturdy yet lightweight frames allows for the construction of efficient and reliable automation solutions.

In robotic applications, T-slot frames can be used to build custom enclosures, supports, and mounting systems. This adaptability ensures that robots can be integrated seamlessly into existing workflows, enhancing productivity and efficiency.

Mechanical Frameworks

In addition to automation, T-slot aluminum extrusions are ideal for constructing mechanical frameworks. These frameworks can support machinery, tools, and equipment, providing a stable foundation for various operations. The modular nature of T-slot extrusions allows for easy adjustments and modifications as machinery evolves or new tools are introduced.

For example, a manufacturing facility may require a new machine to be added to its production line. With T-slot aluminum extrusions, the framework can be quickly adapted to accommodate the new equipment without significant downtime.

Transportation and Logistics

T-slot aluminum extrusions also find applications in transportation and logistics. They can be used to create shelving systems, storage units, and transport frames. The lightweight yet robust nature of aluminum makes it an ideal choice for these applications, as it can withstand the rigors of shipping and handling.

In logistics, T-slot frames can be designed to fit specific cargo dimensions, ensuring that products are securely transported. This customization reduces the risk of damage during transit and optimizes space utilization.

Assembly and Design Tips

Effective Assembly Techniques

Assembling T-slot aluminum extrusions is straightforward, thanks to their user-friendly design. Here are some effective assembly techniques to consider:

- Use of Corner Brackets: Corner brackets can provide additional stability to your frame. They help secure joints and prevent movement, ensuring that your structure remains rigid.

- Proper Fastening: Utilize the appropriate fasteners for your specific application. T-slot extrusions often use bolts and nuts that fit into the T-slots, allowing for secure connections without the need for welding or complex tools.

- Alignment Tools: Employ alignment tools to ensure that all components are correctly positioned during assembly. This will help maintain the integrity of the structure and prevent misalignment issues.

Design Considerations

When designing with T-slot aluminum extrusions, keep the following considerations in mind:

- Load Requirements: Assess the load requirements of your project to determine the appropriate size and profile of the extrusions. This will ensure that your structure can support the intended weight without compromising safety.

- Future Modifications: Design your frame with future modifications in mind. Incorporating additional slots or leaving space for future components can save time and resources down the line.

- Aesthetic Appeal: While functionality is crucial, consider the aesthetic aspects of your design. T-slot aluminum extrusions can be finished in various colors and styles, allowing you to create visually appealing structures.

Conclusion

T-slot aluminum extrusions offer a multitude of benefits for various projects, from industrial automation to mechanical frameworks and logistics. Their lightweight design, modular construction, and flexibility make them an ideal choice for engineers and designers seeking efficient and customizable solutions. By understanding the advantages and applications of T-slot aluminum extrusions, you can leverage their potential to enhance your projects and streamline your processes.

Related Questions

1. What are the main advantages of using aluminum extrusion frames in construction?

Aluminum extrusion frames are lightweight, durable, and resistant to corrosion, making them ideal for construction. Their modular design allows for easy assembly and customization, which can save time and costs.

2. How do T-slot aluminum extrusions compare to traditional framing materials?

T-slot aluminum extrusions are lighter and more versatile than traditional materials like steel or wood. They offer greater flexibility in design and can be easily modified or reconfigured as needed.

3. Can T-slot aluminum extrusions be used for outdoor applications?

Yes, T-slot aluminum extrusions are suitable for outdoor applications due to their resistance to corrosion and weathering. However, it is essential to consider the specific environmental conditions and choose appropriate finishes.

4. What tools are needed to assemble T-slot aluminum extrusions?

Basic tools such as a wrench, screwdriver, and alignment tools are typically sufficient for assembling T-slot aluminum extrusions. Specialized fasteners designed for T-slot systems are also required.

5. Are there any limitations to using T-slot aluminum extrusions?

While T-slot aluminum extrusions are highly versatile, they may not be suitable for applications requiring extreme strength or heavy loads. It is essential to assess the specific requirements of your project to determine if T-slot extrusions are the right choice.