Content Menu

● Understanding T-Slot Aluminum Extrusions

● Advantages of T-Slot Aluminum Extrusions

>> Versatility

>> Ease of Assembly

>> Customization and Flexibility

>> Cost-Effectiveness

● Case Studies

● Conclusion

● Related Questions

>> 1. What materials are commonly used for T-slot aluminum extrusions?

>> 2. How do T-slot aluminum extrusions compare to traditional framing materials?

>> 3. Can T-slot aluminum extrusions be used outdoors?

>> 4. What tools are needed to assemble T-slot aluminum extrusions?

>> 5. How can I ensure the stability of structures built with T-slot aluminum extrusions?

Understanding T-Slot Aluminum Extrusions

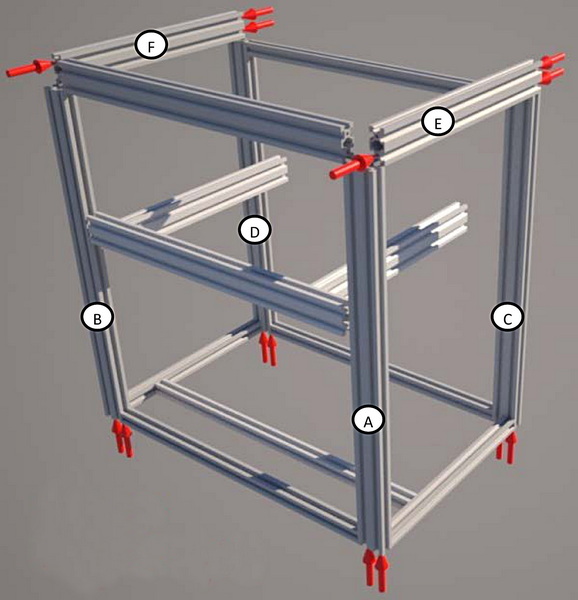

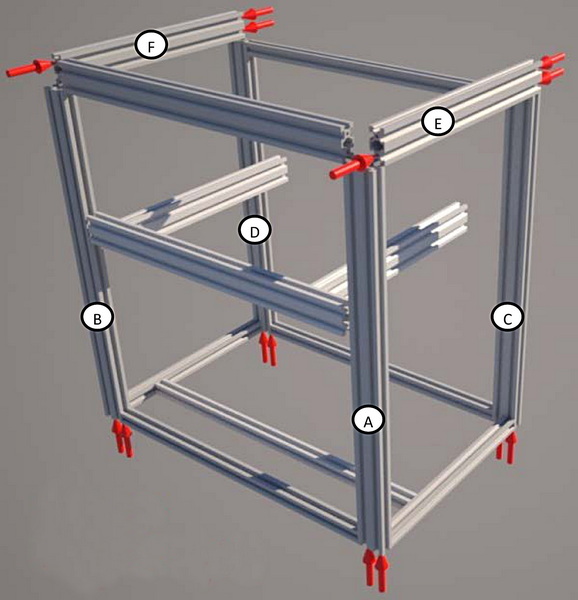

T-slot aluminum extrusions are structural components made from aluminum that feature a unique T-shaped groove along their length. This design allows for easy assembly and disassembly, making them ideal for modular construction. The extrusions are typically made from high-quality aluminum alloys, such as 6061 and 6063, which provide excellent strength-to-weight ratios and corrosion resistance.

The T-slot design facilitates the attachment of various accessories, such as brackets, connectors, and fasteners, enabling users to create custom configurations tailored to specific needs. This adaptability is a key reason why T-slot aluminum extrusions are widely used in industries ranging from manufacturing to robotics and beyond.

Advantages of T-Slot Aluminum Extrusions

Versatility

One of the most significant advantages of T-slot aluminum extrusions is their versatility. These components can be used in a wide range of applications, including:

- Workstations: T-slot aluminum extrusions can be configured to create ergonomic workstations that enhance productivity and comfort. The modular nature allows for easy adjustments as needs change.

- Industrial Racks: They are ideal for building storage solutions, such as shelving and racks, that can be customized to fit specific spaces and requirements.

- Machine Frames: T-slot aluminum extrusions provide a robust framework for machinery, ensuring stability and support while allowing for easy modifications.

The ability to adapt T-slot aluminum extrusions for various applications makes them a valuable asset in any industrial setting.

Ease of Assembly

T-slot aluminum extrusions are designed for quick and straightforward assembly. Unlike traditional materials that may require welding or complex fastening methods, T-slot systems utilize T-bolts and connectors that can be easily inserted into the grooves. This feature significantly reduces assembly time and labor costs.

Moreover, the modular design allows for easy reconfiguration. If a workspace needs to be altered or expanded, users can simply disassemble and reassemble the components without the need for specialized tools or skills. This ease of assembly is particularly beneficial in fast-paced environments where adaptability is crucial.

Customization and Flexibility

T-slot aluminum extrusions offer unparalleled customization options. Users can design their frameworks to meet specific requirements, whether for a unique workstation layout or a specialized machine frame. The ability to mix and match different extrusion sizes and profiles allows for creative solutions that can accommodate various loads and functions.

Additionally, T-slot systems can be easily integrated with other materials and technologies. For instance, users can incorporate panels, shelves, or even electronic components into their designs, creating a comprehensive solution that meets all operational needs.

Cost-Effectiveness

When considering the long-term benefits, T-slot aluminum extrusions prove to be a cost-effective solution. While the initial investment may be higher than some traditional materials, the savings in labor, time, and flexibility often outweigh the costs. The ease of assembly and reconfiguration means that businesses can adapt their setups without incurring significant expenses.

Furthermore, aluminum's durability and resistance to corrosion ensure that T-slot systems have a long lifespan, reducing the need for frequent replacements. This longevity contributes to overall cost savings, making T-slot aluminum extrusions a smart investment for any organization.

Case Studies

To illustrate the effectiveness of T-slot aluminum extrusions, consider the following examples from various industries:

- Automotive Industry: A leading automotive manufacturer implemented T-slot aluminum extrusions to create flexible assembly lines. The modular design allowed for quick adjustments to the production layout, resulting in increased efficiency and reduced downtime.

- Medical Equipment: A medical device company utilized T-slot aluminum extrusions to build custom workstations for their assembly processes. The ergonomic designs improved worker comfort and productivity, leading to higher output rates.

- Robotics: A robotics firm adopted T-slot aluminum extrusions to construct lightweight frames for their robotic arms. The ability to easily modify the designs allowed for rapid prototyping and testing, accelerating their development cycles.

These case studies highlight the adaptability and effectiveness of T-slot aluminum extrusions across different sectors, showcasing their potential to enhance productivity and innovation.

Conclusion

T-slot aluminum extrusions represent a significant advancement in modular framing solutions. Their versatility, ease of assembly, customization options, and cost-effectiveness make them an ideal choice for a wide range of applications. As industries continue to evolve and demand more flexible solutions, T-slot aluminum extrusions will undoubtedly play a crucial role in shaping the future of manufacturing and construction.

By embracing the benefits of T-slot aluminum extrusions, businesses can enhance their operational efficiency, reduce costs, and create innovative designs that meet the ever-changing demands of the market.

Related Questions

1. What materials are commonly used for T-slot aluminum extrusions?

T-slot aluminum extrusions are typically made from high-quality aluminum alloys, such as 6061 and 6063, which provide excellent strength and corrosion resistance.

2. How do T-slot aluminum extrusions compare to traditional framing materials?

T-slot aluminum extrusions offer greater flexibility, ease of assembly, and customization options compared to traditional materials like steel or wood.

3. Can T-slot aluminum extrusions be used outdoors?

Yes, T-slot aluminum extrusions are resistant to corrosion, making them suitable for outdoor applications, provided they are properly maintained.

4. What tools are needed to assemble T-slot aluminum extrusions?

Assembling T-slot aluminum extrusions typically requires basic tools such as an Allen wrench, a screwdriver, and a measuring tape. No specialized tools are necessary.

5. How can I ensure the stability of structures built with T-slot aluminum extrusions?

To ensure stability, it is essential to use appropriate connectors and fasteners, follow design guidelines, and consider the load requirements of the structure.