Content Menu

● Understanding Aluminum Extrusion

● Key Benefits of Aluminum Extrusion Boxes

● Applications of Aluminum Extrusion Boxes

● The Manufacturing Process

● Additional Advantages of Aluminum Extrusion Boxes

>> 1. Cost-Effectiveness

>> 2. Sustainability

>> 3. Ease of Assembly

>> 4. High Resistance to UV Radiation

>> 5. Non-Magnetic Properties

● Choosing the Right Aluminum Extrusion Box

● Conclusion

● FAQ

>> 1. What is an aluminum extrusion box?

>> 2. How does the aluminum extrusion process work?

>> 3. What industries commonly use aluminum extrusion boxes?

>> 4. Are aluminum extrusion boxes resistant to corrosion?

>> 5. Can I customize the size and shape of an aluminum extrusion box?

Aluminum extrusion boxes have become increasingly popular in various industries due to their unique properties and versatility. This article explores the numerous benefits of using aluminum extrusion boxes, detailing their applications, advantages, and why they are an excellent choice for your projects.

Understanding Aluminum Extrusion

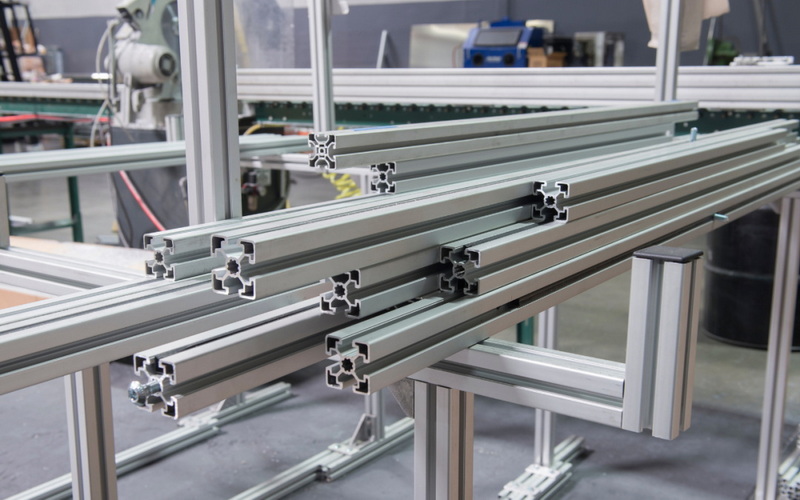

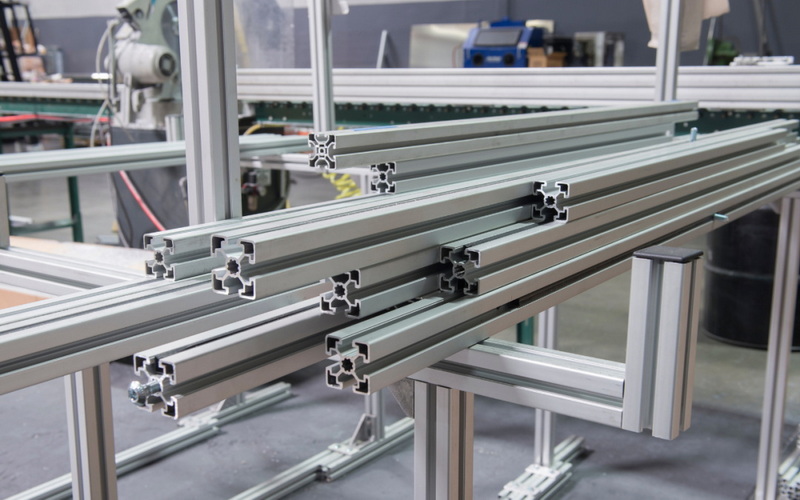

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile by forcing it through a die. This method allows for the creation of complex shapes that can be tailored to specific requirements. The resulting aluminum extrusion boxes are lightweight yet strong, making them suitable for a wide range of applications.

Key Benefits of Aluminum Extrusion Boxes

1. Strength and Durability

- Aluminum extrusion boxes are known for their high strength-to-weight ratio. Aluminum can withstand significant stress without deforming, making it ideal for demanding applications. The tensile strength of aluminum can reach up to 300 MPa, ensuring that these boxes can handle various loads effectively.

2. Corrosion Resistance

- One of the standout features of aluminum is its natural resistance to corrosion. When exposed to air, aluminum forms a protective oxide layer that prevents further oxidation. This characteristic is particularly beneficial in harsh environments where moisture and chemicals are present, such as marine applications.

3. Customization Options

- The flexibility of the aluminum extrusion process allows for extensive customization. Manufacturers can create boxes in various shapes and sizes to meet specific project requirements. This adaptability is crucial for projects that demand tailored solutions.

4. Lightweight Design

- Aluminum is significantly lighter than other metals like steel, making aluminum extrusion boxes easier to handle and transport. This lightweight nature contributes to reduced shipping costs and simplifies installation processes.

5. Thermal Conductivity

- Aluminum has excellent thermal conductivity, which makes it suitable for applications requiring heat dissipation, such as electronic enclosures. This property helps maintain optimal operating temperatures for sensitive components.

6. Electromagnetic Interference (EMI) Shielding

- Extruded aluminum boxes provide effective shielding against electromagnetic interference, protecting sensitive electronics from signal disruption. This feature is essential in industries where electronic performance is critical.

7. Aesthetic Appeal

- Aluminum extrusion boxes can be finished in various ways, including anodizing and powder coating, allowing for aesthetic enhancements while maintaining functionality. These finishes can improve corrosion resistance and provide a visually appealing product.

Applications of Aluminum Extrusion Boxes

Aluminum extrusion boxes are utilized across multiple sectors due to their versatility:

- Electronics: Used as enclosures for circuit boards and other electronic components.

- Telecommunications: Protects equipment from environmental factors like dust and moisture.

- Automotive: Lightweight yet durable enclosures for battery housings and control units.

- Medical Devices: Provides a sterile environment while ensuring safety and durability.

- Renewable Energy: Frames for solar panels and wind turbines benefit from aluminum's strength and resistance to weather conditions.

The Manufacturing Process

The process of creating an aluminum extrusion box involves several steps:

1. Design: Engineers create detailed designs based on project specifications.

2. Die Creation: A custom die is manufactured to shape the aluminum during extrusion.

3. Extrusion: Heated aluminum billets are pushed through the die to form the desired shape.

4. Cooling: The extruded profiles are cooled to solidify.

5. Finishing: Surface treatments like anodizing or powder coating enhance durability and aesthetics.

Additional Advantages of Aluminum Extrusion Boxes

1. Cost-Effectiveness

While the initial costs of manufacturing custom aluminum extrusion boxes may be higher than some alternatives, their long-term benefits often outweigh these expenses. Their durability means less frequent replacements, reducing overall costs over time.

2. Sustainability

Aluminum is one of the most recycled materials globally, making it an environmentally friendly choice for manufacturers concerned about sustainability. Using recycled aluminum reduces energy consumption and greenhouse gas emissions compared to producing new aluminum from raw materials.

3. Ease of Assembly

Aluminum extrusion boxes can be easily assembled using standard fasteners or adhesives, which streamlines the production process. This ease of assembly can lead to quicker project completion times and reduced labor costs.

4. High Resistance to UV Radiation

Aluminum does not degrade when exposed to ultraviolet (UV) radiation, making it an excellent choice for outdoor applications where sun exposure is a concern. This property ensures that the structural integrity and appearance of the box remain intact over time.

5. Non-Magnetic Properties

Aluminum's non-magnetic nature makes it suitable for applications in sensitive environments where magnetic interference could pose problems, such as in certain medical or scientific equipment.

Choosing the Right Aluminum Extrusion Box

When selecting an aluminum extrusion box for your project, consider the following factors:

1. Application Requirements: Assess the specific needs of your project, including size, weight capacity, environmental conditions, and any regulatory standards that must be met.

2. Material Specifications: Different aluminum alloys offer varying properties such as strength, weight, corrosion resistance, and thermal conductivity; choose one that aligns with your project's demands.

3. Customization Needs: Determine whether you require custom shapes or sizes that may necessitate a bespoke design process.

4. Finishing Options: Decide on any surface treatments or finishes that may enhance performance or aesthetics based on your project's context.

5. Budget Considerations: Factor in both initial costs and long-term savings when evaluating options; investing in quality materials can lead to lower maintenance costs over time.

Conclusion

In summary, aluminum extrusion boxes offer numerous benefits that make them an ideal choice for various projects across industries. Their strength, durability, corrosion resistance, customization options, lightweight design, thermal conductivity, EMI shielding capabilities, aesthetic appeal, cost-effectiveness, sustainability, ease of assembly, high resistance to UV radiation, and non-magnetic properties contribute to their increasing popularity in modern manufacturing and design.

By choosing aluminum extrusion boxes for your projects, you can ensure high performance while also enjoying the flexibility needed for custom solutions tailored specifically to your needs.

FAQ

1. What is an aluminum extrusion box?

An aluminum extrusion box is a container made from extruded aluminum profiles designed to protect electronic components or other sensitive materials from environmental factors.

2. How does the aluminum extrusion process work?

The process involves heating aluminum billets and forcing them through a custom die to create specific shapes or profiles required for various applications.

3. What industries commonly use aluminum extrusion boxes?

Industries such as electronics, telecommunications, automotive, medical devices, and renewable energy frequently utilize aluminum extrusion boxes due to their versatility.

4. Are aluminum extrusion boxes resistant to corrosion?

Yes, aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion in various environments.

5. Can I customize the size and shape of an aluminum extrusion box?

Absolutely! The aluminum extrusion process allows for extensive customization in size and shape to meet specific project needs.