Content Menu

● Introduction to Aluminum Extruders

>> How Aluminum Extruders Work

● Benefits of Using an Aluminum Extruder with Adjustable Spring

>> 1. Improved Filament Grip

>> 2. Enhanced Print Quality

>> 3. Increased Versatility

>> 4. Reduced Maintenance

>> 5. Cost-Effective

● Applications of Aluminum Extruders

● Advantages of Aluminum in 3D Printing

● Customization and Upgrades

>> Modifying Spring Tension

● Aluminum Extrusion in Various Industries

● Future Developments

● Conclusion

● FAQ

>> 1. What is the main advantage of using an aluminum extruder with adjustable spring?

>> 2. How does the adjustable spring improve print quality?

>> 3. Can an aluminum extruder with adjustable spring handle flexible filaments?

>> 4. Is an aluminum extruder with adjustable spring cost-effective?

>> 5. What are some common applications of aluminum extruders?

● Citations:

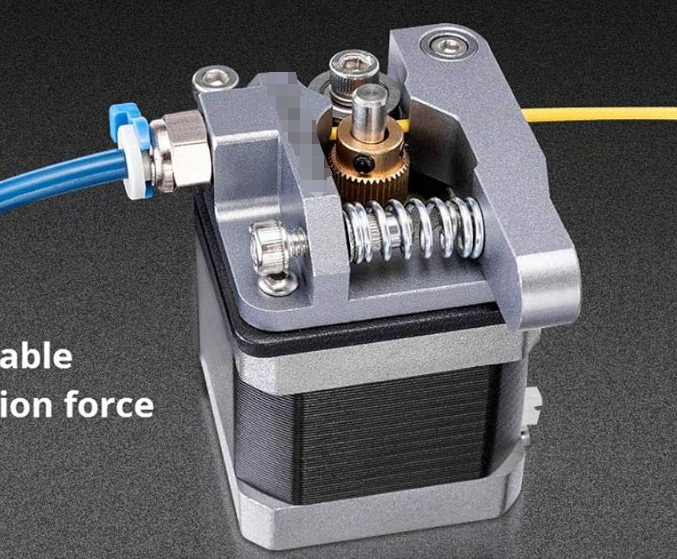

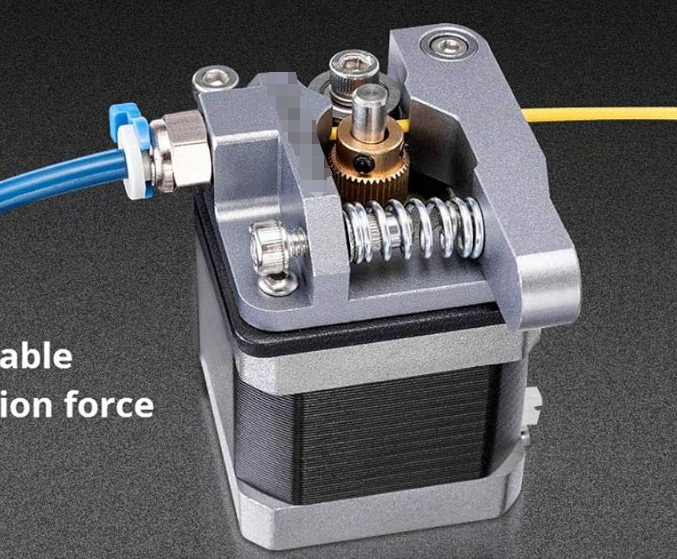

The use of an aluminum extruder with adjustable spring in 3D printing has become increasingly popular due to its numerous benefits. This type of extruder offers enhanced performance, reliability, and flexibility compared to traditional extruders. In this article, we will delve into the advantages of using an aluminum extruder with adjustable spring, explore how it works, and discuss its applications in various fields.

Introduction to Aluminum Extruders

Aluminum extruders are widely used in 3D printing due to their durability and ability to maintain consistent temperatures, which is crucial for stable extrusion. The aluminum extruder with adjustable spring takes this a step further by allowing users to fine-tune the tension on the filament, ensuring optimal grip and minimizing issues like under-extrusion or filament breakage.

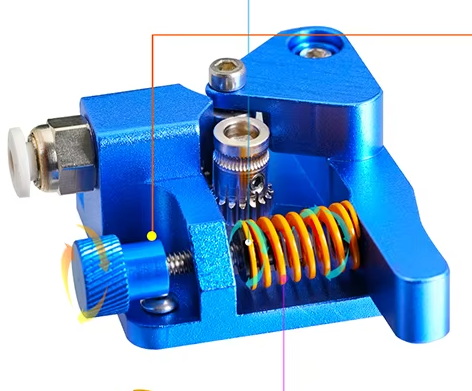

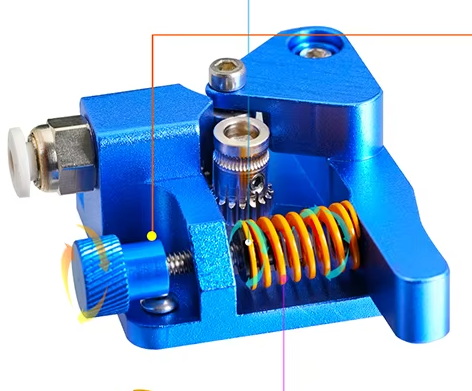

How Aluminum Extruders Work

Aluminum extruders work by using a combination of gears and springs to grip and push the filament through the hotend. The adjustable spring allows users to adjust the tension applied to the filament, which is essential for different types of filaments that have varying hardness and flexibility.

Benefits of Using an Aluminum Extruder with Adjustable Spring

1. Improved Filament Grip

The adjustable spring in an aluminum extruder ensures that the filament is gripped firmly but not too tightly, reducing the risk of filament breakage or grinding. This is particularly beneficial for brittle filaments like PLA or PETG.

2. Enhanced Print Quality

By adjusting the spring tension, users can optimize the extrusion flow, leading to more consistent and higher-quality prints. This is especially important for detailed prints where precision is key.

3. Increased Versatility

The aluminum extruder with adjustable spring can handle a wide range of filaments, from flexible materials like TPU to rigid ones like ABS. This versatility makes it a valuable asset for any 3D printing setup.

4. Reduced Maintenance

Adjusting the spring tension can help prevent common issues like clogging or filament jamming, reducing the need for frequent maintenance and cleaning.

5. Cost-Effective

While the initial cost of an aluminum extruder with adjustable spring might be higher than a basic extruder, its durability and ability to handle various filaments make it a cost-effective option in the long run.

Applications of Aluminum Extruders

Aluminum extruders are used in a variety of applications, from hobbyist 3D printing to industrial manufacturing. Their ability to handle complex prints and maintain consistent quality makes them ideal for:

- Aerospace: Lightweight yet strong components are crucial in aerospace applications.

- Automotive: Aluminum extrusions are used in crash management systems due to their resilience.

- Consumer Products: From phone cases to furniture, aluminum extruders help create durable and versatile products.

Advantages of Aluminum in 3D Printing

Aluminum's unique properties make it an ideal material for 3D printing components:

- Lightweight Strength: Aluminum provides a high strength-to-weight ratio, allowing for faster print speeds and reduced printer weight[1].

- Durability and Wear Resistance: Aluminum extruders are resistant to wear and tear, ensuring long-term reliability[1].

- Thermal Conductivity: Aluminum's ability to dissipate heat helps prevent clogging and maintains stable operating temperatures[1].

Customization and Upgrades

Users can customize their aluminum extruder with adjustable spring by modifying the spring tension to suit different filaments. For example, reducing spring tension can help with flexible filaments or prevent filament breakage during retraction[3].

Modifying Spring Tension

Modifying the spring tension involves simple steps like drilling and tapping the tensioner screw hole and adjusting the spring length. This allows users to achieve optimal filament grip without over-tightening, which can lead to filament damage[3].

Aluminum Extrusion in Various Industries

Beyond 3D printing, aluminum extrusions are widely used in industries such as:

- Automotive: For engine blocks, transmission housings, and vehicle chassis due to their strength-to-weight ratio[5][7].

- Electronics: In heat sinks and cooling systems due to aluminum's thermal conductivity[5][7].

- Construction: For structural components that resist weather distortion[5][7].

Future Developments

As technology advances, the potential for aluminum in 3D printing will expand. New manufacturing processes like the HyperAl method are improving the strength and efficiency of aluminum extrusions, which could lead to more innovative applications in the future[2].

Conclusion

The aluminum extruder with adjustable spring offers numerous benefits for 3D printing enthusiasts and professionals alike. Its ability to handle a wide range of filaments, improve print quality, and reduce maintenance needs make it a valuable addition to any 3D printing setup.

FAQ

1. What is the main advantage of using an aluminum extruder with adjustable spring?

The main advantage is the ability to adjust the tension on the filament, ensuring optimal grip and minimizing issues like under-extrusion or filament breakage.

2. How does the adjustable spring improve print quality?

By allowing users to optimize the extrusion flow, the adjustable spring ensures consistent and precise extrusion, leading to higher-quality prints.

3. Can an aluminum extruder with adjustable spring handle flexible filaments?

Yes, it can handle a wide range of filaments, including flexible materials like TPU, by adjusting the spring tension to accommodate different filament types.

4. Is an aluminum extruder with adjustable spring cost-effective?

While initially more expensive, its durability and versatility make it a cost-effective option in the long run by reducing maintenance and allowing for a variety of filament uses.

5. What are some common applications of aluminum extruders?

Aluminum extruders are used in aerospace, automotive, and consumer products due to their strength, lightweight nature, and versatility.

Citations:

[1] https://www.yjing-extrusion.com/why-should-you-choose-an-aluminum-extruder-for-3d-printing.html

[2] https://aec.org/et-seminar-end-use-sessions

[3] https://www.reddit.com/r/ender3v2/comments/174wztz/extruder_spring_tension_mod/

[4] https://www.yjing-extrusion.com/what-are-the-benefits-of-using-aluminum-extrusion-in-3d-printing.html

[5] https://kimsen.vn/uses-of-aluminum-extrusion-ne37.html

[6] https://www.cnclathing.com/guide/process-of-aluminum-extrusion-in-steps-advantages-of-aluminum-extrusion-process

[7] https://www.hydro.com/profiles/uses-of-aluminum-extrusions

[8] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[9] https://garrettgoss.com/blog/2019/05/extruded-aluminum-3d-printer.html

[10] https://www.cnckitchen.com/blog/which-is-the-strongest-3d-printing-extruder

[11] https://tricityextrusion.com/roxyfileman/uploads/AEC_2018_Aluminum_Extrusion_Manual.pdf

[12] https://aec.org/features-benefits

[13] https://www.reddit.com/r/3Dprinting/comments/lbtobl/what_is_the_benefit_of_a_metal_extruder_for_an/

[14] https://www.kobelco.co.jp/english/ktr/pdf/ktr_35/069-075.pdf

[15] https://innovativeidm.com/2015/08/26/aluminum_extrusion_vs_welded_steel/

[16] https://all3dp.com/2/3d-printer-extruder-guide/

[17] https://amcaluminum.ph/common-applications-of-aluminum-extrusion/

[18] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[19] https://www.aliexpress.com/item/1005004573868160.html

[20] https://extrusion-dies.ru/assets/files/Aluminum_Extrusion_Technology_P_Saha.pdf