Content Menu

● Introduction

● Understanding Aluminum Extrusion

>> Types of Aluminum Extrusions Commonly Used in 3D Printing

● Advantages of Aluminum Extrusion in 3D Printing

>> Lightweight and Strong

>> Cost-Effectiveness

>> Versatility

● Enhancing 3D Printer Performance with Aluminum Extrusions

>> Stability and Precision

>> Examples of Successful 3D Printers Utilizing Aluminum Extrusion

● Best Practices for Using Aluminum in 3D Printing

>> Selecting the Right Aluminum Profiles

>> Maintenance and Care for Aluminum Components

● Future Trends in Aluminum Extrusion and 3D Printing

>> Innovations in Aluminum Materials and Extrusion Techniques

>> Predictions for the Future of Additive Manufacturing with Aluminum

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum extrusion in 3D printing?

>> 2. How does aluminum extrusion improve the stability of 3D printers?

>> 3. Can aluminum extrusions be customized for specific 3D printing needs?

>> 4. What maintenance is required for aluminum components in 3D printers?

>> 5. What future trends can we expect in aluminum extrusion and 3D printing?

Introduction

In recent years, 3D printing has revolutionized the manufacturing landscape, offering unprecedented flexibility and efficiency. Among the various materials used in 3D printing, aluminum extrusion stands out as a popular choice due to its unique properties and advantages. This article explores the benefits of using aluminum extrusion in 3D printing, highlighting its significance in enhancing printer performance, reducing costs, and improving the overall quality of printed objects.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process creates long sections of aluminum with a constant cross-sectional profile, which can be cut to desired lengths. The versatility of aluminum extrusion allows for the creation of complex shapes and designs, making it an ideal material for various applications, including 3D printing.

Types of Aluminum Extrusions Commonly Used in 3D Printing

There are several types of aluminum extrusions that are commonly utilized in 3D printing:

- T-Slot Aluminum Extrusions: These are widely used for building 3D printer frames. The T-slot design allows for easy assembly and modification, enabling users to customize their printer setups according to their specific needs.

- Aluminum Profiles: These are pre-fabricated sections of aluminum that can be used for various structural components in 3D printers, such as supports, brackets, and enclosures.

- Custom Extrusions: For specialized applications, custom aluminum extrusions can be designed to meet specific requirements, providing tailored solutions for unique 3D printing projects.

Advantages of Aluminum Extrusion in 3D Printing

Lightweight and Strong

One of the most significant benefits of aluminum extrusion is its lightweight nature combined with high strength. Aluminum is known for its excellent strength-to-weight ratio, making it an ideal choice for 3D printer frames. A lightweight frame reduces the overall weight of the printer, allowing for faster movement and improved print speeds. Additionally, the strength of aluminum ensures that the printer remains stable during operation, resulting in higher precision and better print quality.

Cost-Effectiveness

When compared to other materials, aluminum extrusion is often more cost-effective. The manufacturing process of aluminum is efficient, and the material itself is relatively inexpensive. This cost advantage extends to the overall production of 3D printed parts, as aluminum extrusions can be produced in large quantities without significant increases in cost. Furthermore, the durability of aluminum means that components made from this material have a longer lifespan, reducing the need for frequent replacements.

Versatility

Aluminum extrusion offers remarkable versatility, making it suitable for a wide range of applications. In the context of 3D printing, aluminum can be used for various components, including frames, supports, and even some print heads. This versatility allows manufacturers to create complex designs and structures that would be challenging to achieve with other materials. Additionally, aluminum can be easily machined, welded, or joined with other materials, further expanding its usability in 3D printing projects.

Enhancing 3D Printer Performance with Aluminum Extrusions

Stability and Precision

The use of aluminum extrusions in 3D printer frames significantly enhances stability and precision. A rigid frame constructed from aluminum minimizes vibrations during the printing process, which is crucial for achieving high-quality prints. The stability provided by aluminum extrusions allows for consistent layer adhesion and accurate dimensional tolerances, resulting in better overall print quality.

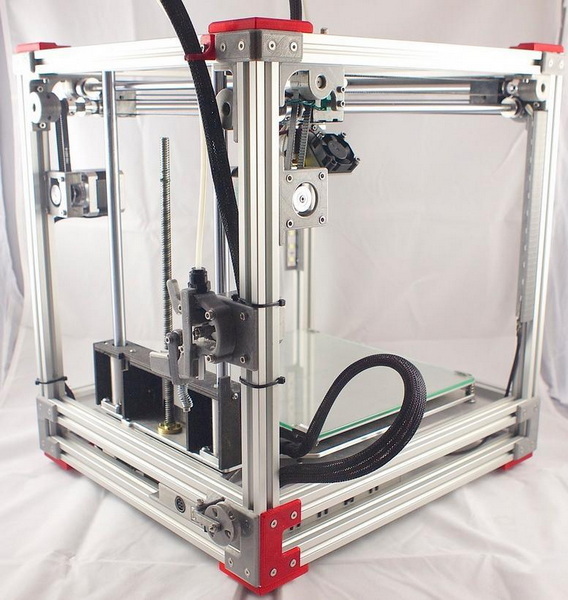

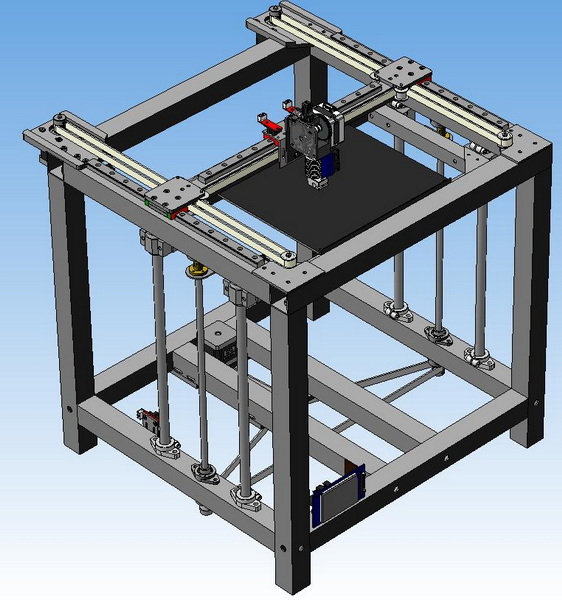

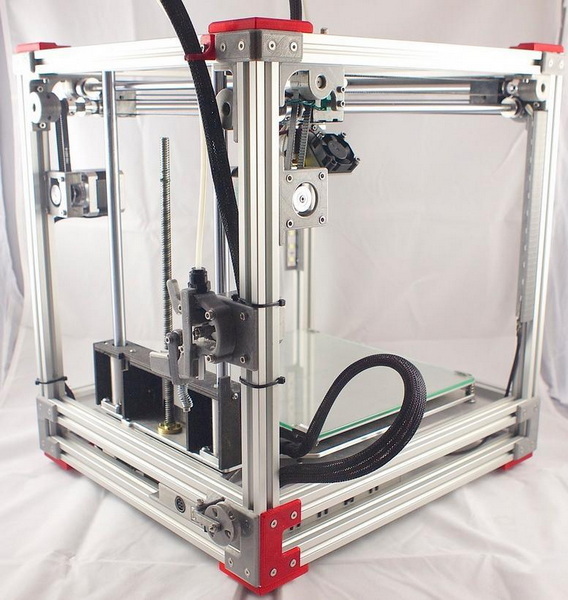

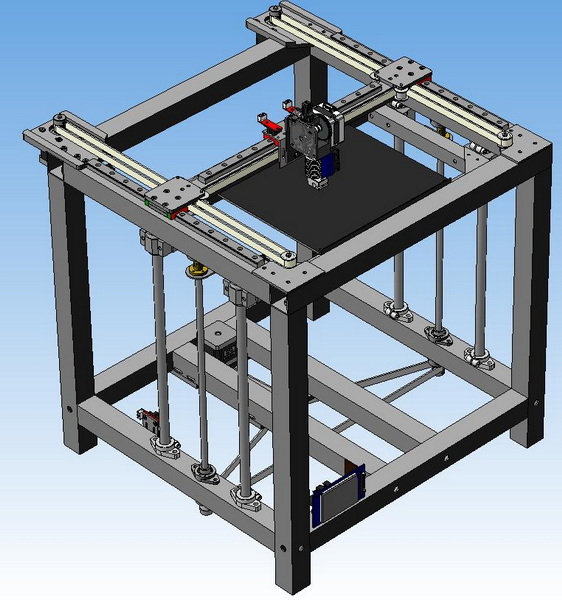

Examples of Successful 3D Printers Utilizing Aluminum Extrusion

Many popular 3D printers on the market today utilize aluminum extrusion in their designs. For instance, the Prusa i3 series is renowned for its robust aluminum frame, which contributes to its reputation for reliability and print quality. Similarly, the Creality Ender series features aluminum extrusions that provide a solid foundation for high-performance printing. These examples illustrate how aluminum extrusion has become a standard in the industry, enabling manufacturers to produce reliable and efficient 3D printers.

Best Practices for Using Aluminum in 3D Printing

Selecting the Right Aluminum Profiles

When choosing aluminum profiles for 3D printing, it is essential to consider the specific requirements of your project. Factors such as the size of the printer, the weight of the components, and the intended use of the printed parts should all influence your selection. T-slot aluminum extrusions are often recommended for their ease of assembly and flexibility, allowing users to create custom printer designs that meet their needs.

Maintenance and Care for Aluminum Components

To ensure the longevity and performance of aluminum components in 3D printers, regular maintenance is crucial. This includes cleaning the extrusions to remove dust and debris, checking for any signs of wear or damage, and ensuring that all connections are secure. Proper maintenance not only extends the life of the printer but also helps maintain print quality over time.

Future Trends in Aluminum Extrusion and 3D Printing

As technology continues to advance, the future of aluminum extrusion in 3D printing looks promising. Innovations in aluminum materials and extrusion techniques are expected to enhance the capabilities of 3D printers further. For instance, the development of new aluminum alloys with improved properties could lead to even lighter and stronger components. Additionally, advancements in additive manufacturing processes may allow for more complex designs and faster production times.

Innovations in Aluminum Materials and Extrusion Techniques

Research is ongoing to develop aluminum alloys that offer enhanced performance characteristics, such as increased corrosion resistance and improved thermal conductivity. These innovations could open new avenues for 3D printing applications, particularly in industries such as aerospace and automotive, where material performance is critical.

Predictions for the Future of Additive Manufacturing with Aluminum

The integration of aluminum extrusion in additive manufacturing is likely to grow, with more manufacturers recognizing its benefits. As 3D printing technology continues to evolve, we can expect to see an increase in the use of aluminum for both structural components and printed parts. This trend will likely lead to more efficient production processes and the ability to create even more complex geometries.

Conclusion

In conclusion, the benefits of using aluminum extrusion in 3D printing are numerous and significant. From its lightweight and strong properties to its cost-effectiveness and versatility, aluminum extrusion has become a preferred choice for many manufacturers and hobbyists alike. By enhancing printer performance and enabling the creation of high-quality printed parts, aluminum extrusion plays a crucial role in the future of additive manufacturing. As technology continues to advance, the potential for aluminum in 3D printing will only expand, paving the way for innovative applications and solutions.

Related Questions

1. What are the main advantages of using aluminum extrusion in 3D printing?

Aluminum extrusion offers lightweight strength, cost-effectiveness, and versatility, making it an ideal choice for 3D printer frames and components.

2. How does aluminum extrusion improve the stability of 3D printers?

The rigidity of aluminum extrusions minimizes vibrations during printing, leading to higher precision and better print quality.

3. Can aluminum extrusions be customized for specific 3D printing needs?

Yes, custom aluminum extrusions can be designed to meet specific project requirements, providing tailored solutions for unique applications.

4. What maintenance is required for aluminum components in 3D printers?

Regular cleaning, checking for wear, and ensuring secure connections are essential for maintaining aluminum components and ensuring optimal performance.

5. What future trends can we expect in aluminum extrusion and 3D printing?

Innovations in aluminum materials and extrusion techniques are expected to enhance the capabilities of 3D printing, leading to more efficient production processes and complex designs.