Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Features of 1515 Aluminum Profiles

● Applications of 1515 Aluminum Profiles

● Advantages of Using 1515 Aluminum Profiles

● Installation and Assembly Tips

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum profiles in construction?

>> 2. How do I choose the right aluminum profile for my project?

>> 3. Can aluminum profiles be used for outdoor applications?

>> 4. What tools do I need to work with aluminum profiles?

>> 5. Are aluminum profiles environmentally friendly?

Introduction

Aluminum extrusion has revolutionized the construction industry, providing versatile and efficient solutions for various applications. Among the many profiles available, the 1515 aluminum profile stands out due to its unique characteristics and benefits. This article explores the advantages of using 1515 aluminum profiles in modular construction, highlighting their features, applications, and installation tips.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing heated aluminum through a die, resulting in a continuous length of material that can be cut to size. The extrusion process allows for the creation of complex shapes and designs, making aluminum an ideal choice for various construction applications.

Aluminum is favored in construction due to its lightweight nature, corrosion resistance, and high strength-to-weight ratio. These properties make it an excellent material for modular construction, where components are prefabricated off-site and assembled on-site. The 1515 aluminum profile, with its specific dimensions and design, offers additional benefits that enhance its usability in modular systems.

Features of 1515 Aluminum Profiles

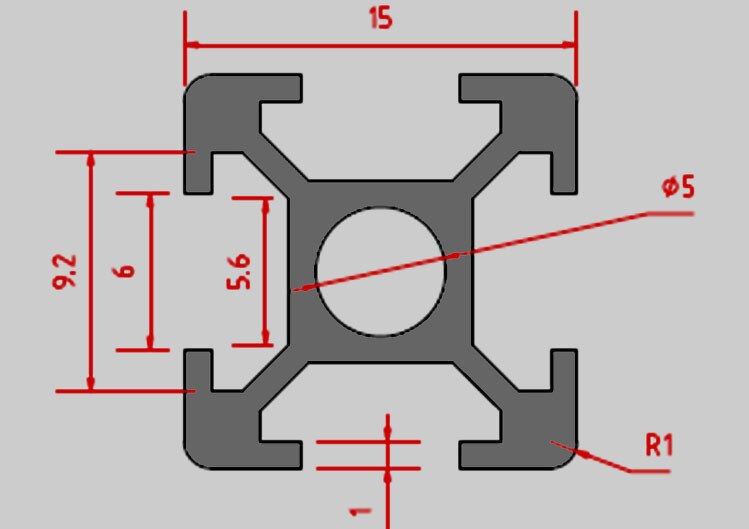

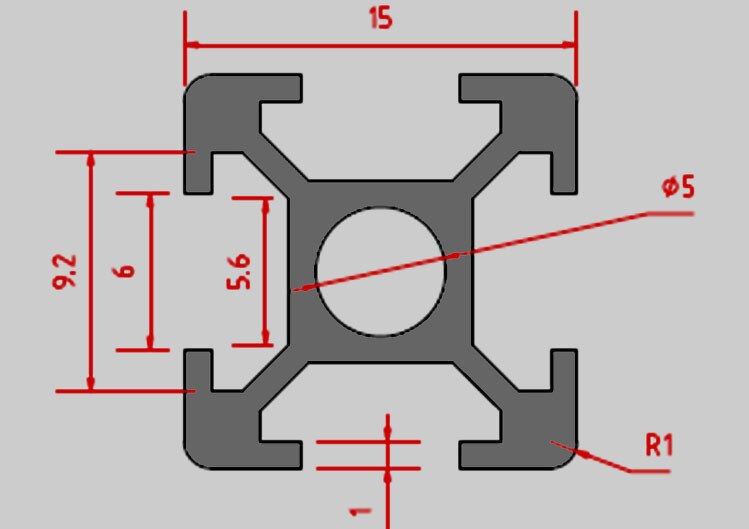

The 1515 aluminum profile is characterized by its dimensions of 15mm x 15mm, making it a compact and versatile option for various applications. Its square shape allows for easy integration with other components, providing flexibility in design and assembly. The profile typically features multiple slots, enabling the attachment of accessories and connectors, which simplifies the construction process.

One of the key advantages of the 1515 profile is its compatibility with a wide range of accessories, such as brackets, fasteners, and connectors. This versatility allows builders to create custom solutions tailored to specific project requirements. Additionally, the profile can be anodized or powder-coated, enhancing its aesthetic appeal and providing additional protection against environmental factors.

Applications of 1515 Aluminum Profiles

1515 aluminum profiles are widely used in modular construction due to their adaptability and strength. They are commonly employed in the following applications:

- Modular Framing Systems: The 1515 profile serves as a structural framework for modular buildings, providing stability and support for walls, roofs, and other components. Its lightweight nature reduces the overall weight of the structure, making it easier to transport and assemble.

- Workstations and Furniture: Many companies utilize 1515 aluminum profiles to create ergonomic workstations and modular furniture. The ability to customize the design allows for the creation of functional and aesthetically pleasing office environments.

- Display and Exhibition Stands: The versatility of the 1515 profile makes it an ideal choice for constructing display stands and exhibition booths. Its lightweight design allows for easy transport and setup, while the modular nature enables quick reconfiguration for different events.

- Automated Systems: In industries such as robotics and automation, 1515 aluminum profiles are used to build frames and supports for machinery and equipment. Their strength and stability ensure reliable performance in demanding environments.

- DIY Projects: Hobbyists and DIY enthusiasts often turn to 1515 aluminum profiles for various projects, from custom shelving units to home automation systems. The ease of assembly and availability of accessories make it a popular choice for creative endeavors.

Advantages of Using 1515 Aluminum Profiles

The benefits of using 1515 aluminum profiles in modular construction are numerous:

- Flexibility in Design and Assembly: The modular nature of the 1515 profile allows for easy customization and reconfiguration. Builders can quickly adapt designs to meet changing project requirements, making it an ideal choice for dynamic construction environments.

- Cost-Effectiveness and Sustainability: Aluminum is a recyclable material, making it an environmentally friendly choice for construction. The lightweight nature of the 1515 profile reduces transportation costs and energy consumption during assembly, contributing to overall project savings.

- Enhanced Structural Integrity and Durability: The strength of aluminum ensures that structures built with 1515 profiles can withstand various environmental conditions. Additionally, anodized or powder-coated finishes provide protection against corrosion, extending the lifespan of the components.

- Ease of Installation: The design of the 1515 profile simplifies the installation process. With pre-drilled holes and compatible accessories, builders can quickly assemble structures without the need for specialized tools or extensive training.

- Aesthetic Appeal: The sleek design of the 1515 aluminum profile allows for modern and attractive constructions. The ability to choose different finishes further enhances the visual appeal of the final product.

Installation and Assembly Tips

When working with 1515 aluminum profiles, consider the following tips to ensure a successful installation:

- Plan Your Design: Before starting the assembly, create a detailed plan of your design. This will help you determine the number of profiles and accessories needed, as well as the overall layout.

- Use the Right Tools: While the installation of 1515 aluminum profiles is straightforward, using the right tools can make the process smoother. A miter saw, drill, and hex key are essential for cutting and assembling the profiles.

- Follow Manufacturer Guidelines: Always refer to the manufacturer's guidelines for specific instructions on assembly and installation. This will ensure that you are using the profiles correctly and safely.

- Check for Level and Alignment: As you assemble the profiles, regularly check for level and alignment. This will help prevent structural issues and ensure a professional finish.

- Secure Connections: Use appropriate fasteners and connectors to secure the profiles together. This will enhance the stability of the structure and prevent any movement over time.

Conclusion

The 1515 aluminum profile offers numerous benefits for modular construction, making it a popular choice among builders and designers. Its flexibility, cost-effectiveness, and durability make it an ideal solution for a wide range of applications. By understanding the features and advantages of 1515 aluminum profiles, construction professionals can leverage this material to create innovative and efficient structures.

Related Questions

1. What are the main advantages of using aluminum profiles in construction?

Aluminum profiles offer lightweight, corrosion resistance, and high strength-to-weight ratios, making them ideal for various construction applications.

2. How do I choose the right aluminum profile for my project?

Consider factors such as the required strength, dimensions, and compatibility with accessories when selecting an aluminum profile for your project.

3. Can aluminum profiles be used for outdoor applications?

Yes, aluminum profiles, especially those with anodized or powder-coated finishes, are suitable for outdoor applications due to their corrosion resistance.

4. What tools do I need to work with aluminum profiles?

Essential tools include a miter saw, drill, hex key, and measuring tape for accurate cutting and assembly of aluminum profiles.

5. Are aluminum profiles environmentally friendly?

Yes, aluminum is a recyclable material, and its lightweight nature reduces energy consumption during transportation and assembly, making it an environmentally friendly choice.