Content Menu

● Understanding Brushed Aluminum Extrusion Finishes

● Benefits of Brushed Aluminum Extrusion Finishes

● The Brushing Process Explained

● Comparison with Other Finishes

● Applications of Brushed Aluminum Extrusions

● Environmental Considerations

● Future Trends in Brushed Aluminum Finishes

● Industry Insights

>> Architectural Design

>> Consumer Electronics

>> Automotive Applications

● Challenges in Working with Brushed Aluminum

● Conclusion

● FAQ

>> 1. What is brushed aluminum?

>> 2. How does brushed aluminum compare to polished aluminum?

>> 3. Can brushed aluminum be anodized?

>> 4. What industries commonly use brushed aluminum?

>> 5. Is brushed aluminum easy to maintain?

● Citations:

Brushed aluminum extrusion finishes are increasingly popular in various industries due to their unique aesthetic appeal and practical benefits. This article explores the advantages of brushed aluminum finishes, their applications, and how they enhance the performance and appearance of aluminum products.

Understanding Brushed Aluminum Extrusion Finishes

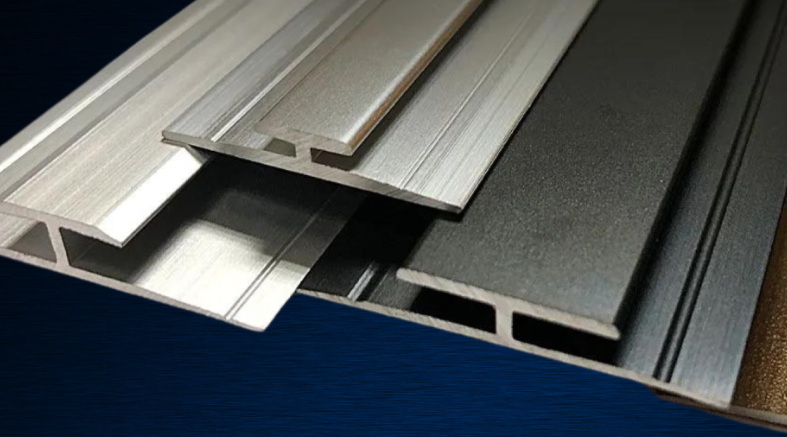

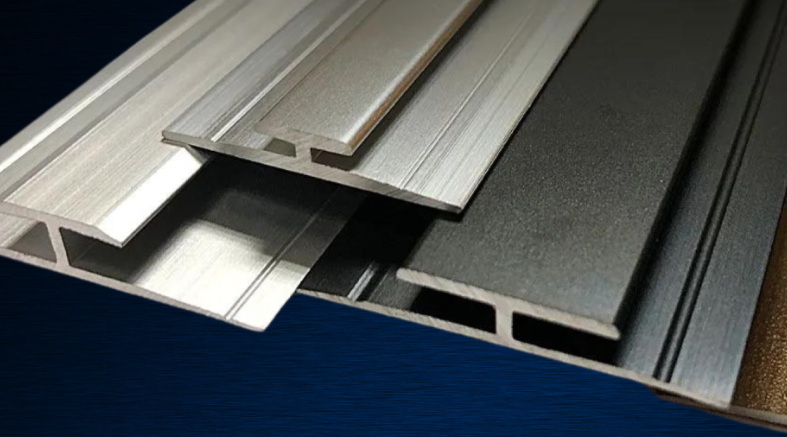

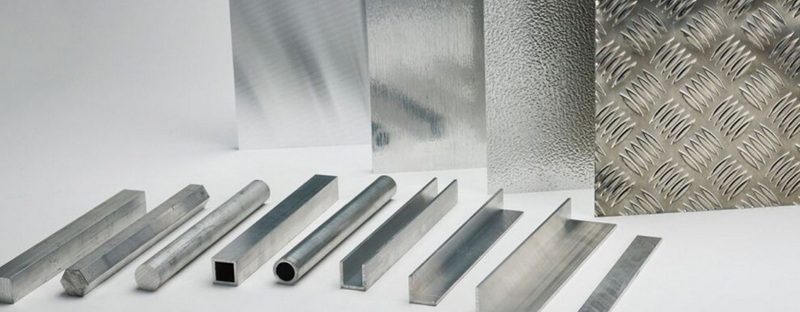

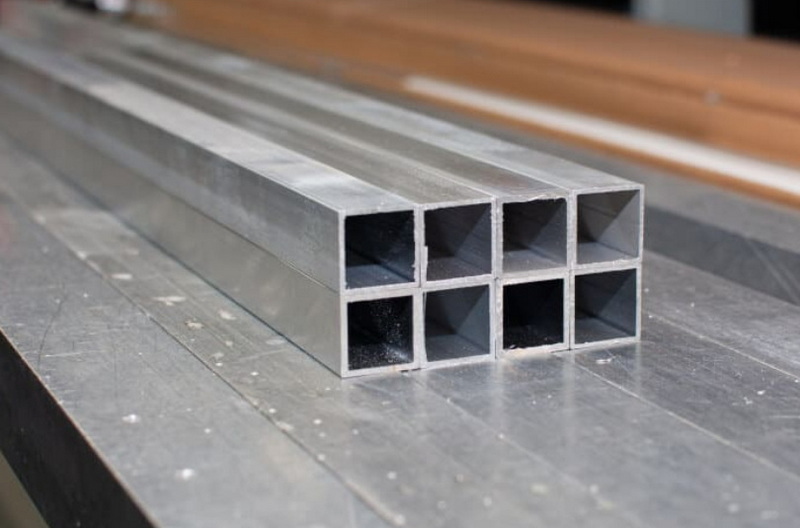

Brushed aluminum is created through a mechanical process that involves polishing the surface of aluminum with abrasive materials. This technique results in a distinctive texture characterized by fine lines that run in one direction, giving the aluminum a sleek, modern look. The brushing process not only improves the visual appeal but also enhances the material's durability and functionality.

Benefits of Brushed Aluminum Extrusion Finishes

1. Aesthetic Appeal

Brushed aluminum offers a sophisticated and contemporary appearance. The unique texture created by the brushing process adds depth and character to aluminum products, making them visually striking. This finish is particularly favored in architectural applications, interior design, and consumer electronics.

2. Surface Defect Concealment

One of the primary advantages of brushed aluminum is its ability to mask minor surface imperfections such as scratches, scuffs, and machining marks. The brushing process effectively smooths out these defects, resulting in a more uniform and attractive surface.

3. Enhanced Durability

The brushing process can significantly improve the durability of aluminum extrusions. Brushed aluminum surfaces are less prone to corrosion and wear compared to untreated surfaces. Additionally, when combined with anodizing or other protective coatings, brushed finishes can offer even greater resistance to environmental factors.

4. Customization Options

Brushed aluminum finishes can be customized to meet specific aesthetic requirements. By adjusting the brushing technique, manufacturers can create various textures and patterns that cater to individual preferences. This flexibility makes brushed finishes suitable for a wide range of applications.

5. Low Maintenance Requirements

Products finished with brushed aluminum are generally easier to maintain than those with high-gloss or polished surfaces. The matte finish helps hide fingerprints and smudges, reducing the frequency of cleaning required to keep the surface looking pristine.

6. Versatile Applications

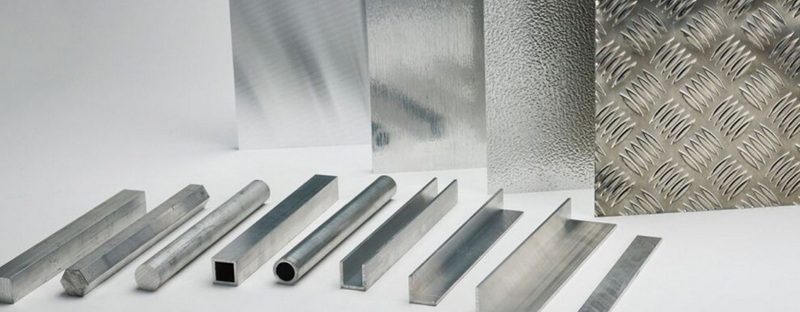

Brushed aluminum extrusions are used in numerous industries due to their versatility. Common applications include:

- Architectural elements such as window frames and door handles

- Consumer electronics like laptops and smartphones

- Kitchen appliances and fixtures

- Furniture design

- Signage and displays

The Brushing Process Explained

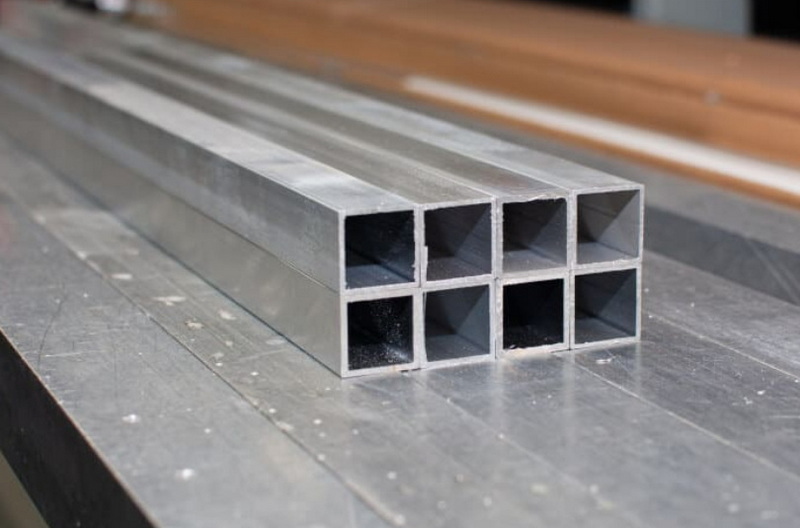

The brushing process typically involves the following steps:

- Preparation: The aluminum extrusion is cleaned to remove any dirt or contaminants.

- Brushing: Abrasive brushes or belts are used to create fine lines on the surface of the aluminum, ensuring a uniform texture.

- Finishing: Additional treatments such as anodizing may be applied to enhance corrosion resistance and aesthetic appeal.

This mechanical process results in a brushed finish that is not only visually appealing but also functional.

Comparison with Other Finishes

When considering finishes for aluminum extrusions, it's important to understand how brushed finishes compare with other options:

| Feature | Brushed Aluminum | Polished Aluminum | Anodized Aluminum |

| Appearance | Matte with fine lines | High gloss | Varies (can be matte or glossy) |

| Surface Defect Concealment | Excellent | Moderate | Good |

| Durability | High | Moderate | Very high |

| Maintenance | Low | High | Low |

| Customization | High | Limited | Moderate |

Applications of Brushed Aluminum Extrusions

Brushed aluminum is widely utilized across various sectors due to its unique properties:

- Architecture: Used for decorative panels, railings, and facades that require both durability and aesthetic appeal.

- Consumer Electronics: Found in devices like smartphones and laptops where a modern look is essential.

- Furniture Design: Ideal for creating sleek furniture pieces that stand out in contemporary interiors.

- Automotive Industry: Used for trim pieces that benefit from both durability and style.

Environmental Considerations

Brushed aluminum finishes can be an environmentally friendly choice as they often require fewer chemicals compared to other finishing processes. Additionally, aluminum itself is highly recyclable, making it a sustainable option for manufacturers looking to reduce their environmental impact.

Future Trends in Brushed Aluminum Finishes

As technology advances, new techniques for applying brushed finishes are being developed. Innovations may include:

- Enhanced automation in the brushing process for greater consistency.

- Integration with digital printing technologies to create custom patterns on brushed surfaces.

- Development of eco-friendly coatings that maintain the aesthetic qualities while providing additional protection.

Industry Insights

The demand for brushed aluminum finishes has surged in recent years due to their versatility and appealing aesthetics. Industries such as construction, automotive, and consumer electronics have increasingly adopted these finishes as part of their design language.

Architectural Design

In architecture, brushed aluminum has become synonymous with modernity. Its use in facades not only enhances visual appeal but also contributes to energy efficiency by reflecting sunlight away from buildings. Architects appreciate brushed finishes for their ability to complement various materials like glass and wood.

Consumer Electronics

In consumer electronics, brushed aluminum provides a premium feel that consumers often associate with quality products. Major brands utilize this finish on devices ranging from laptops to smartphones, creating an elegant look that stands out on retail shelves.

Automotive Applications

The automotive industry has also embraced brushed finishes for both interior and exterior components. Trim pieces made from brushed aluminum add a touch of luxury while maintaining durability against harsh weather conditions.

Challenges in Working with Brushed Aluminum

Despite its many benefits, there are challenges associated with working with brushed aluminum:

- Cost Considerations: The brushing process can add additional costs compared to simpler finishing methods like anodizing or painting.

- Repair Difficulties: If a brushed surface becomes damaged, repairs can be challenging since matching the original texture may require specialized equipment.

- Limited Color Options: While anodizing can provide color options for brushed surfaces, the range is still more limited compared to painted finishes.

Conclusion

Brushed aluminum extrusion finishes offer numerous benefits that enhance both the functionality and aesthetics of products across various industries. Their ability to conceal surface defects, coupled with low maintenance requirements and customization options, makes them an attractive choice for manufacturers and designers alike. As trends evolve, brushed aluminum will likely continue to play a significant role in modern design and manufacturing practices.

FAQ

1. What is brushed aluminum?

Brushed aluminum is an aluminum finish achieved by polishing the surface with abrasive materials, creating fine lines that give it a sleek appearance.

2. How does brushed aluminum compare to polished aluminum?

Brushed aluminum has a matte finish with fine lines, while polished aluminum has a high-gloss reflective surface. Brushed finishes are generally more durable against scratches.

3. Can brushed aluminum be anodized?

Yes, brushed aluminum can be anodized after the brushing process to enhance its corrosion resistance and provide additional color options.

4. What industries commonly use brushed aluminum?

Brushed aluminum is widely used in architecture, consumer electronics, furniture design, automotive parts, and signage due to its versatility.

5. Is brushed aluminum easy to maintain?

Yes, brushed aluminum requires less maintenance than polished surfaces as it hides fingerprints and smudges effectively.

Citations:

[1] https://www.boyiprototyping.com/surface-finishing-guide/brushed-aluminum/

[2] https://www.machine4aluminium.com/aluminum-profile-brushing-process-and-advantages/

[3] https://www.alu4all.com/enhance-your-custom-aluminum-extrusions-with-these-finishes/

[4] https://www.alamy.com/stock-photo/aluminium-profile.html

[5] https://www.youtube.com/watch?v=vHkwq_2yY9E

[6] https://shengenfab.com/types-of-aluminum-finishes/

[7] https://www.yg-enclosure.com/article/why-brushed-anodizing-for-your-aluminum-finish.html

[8] https://kimsen.vn/the-6-types-of-finishes-that-will-enhance-your-aluminum-extrusions-ne85.html

[9] https://www.dreamstime.com/photos-images/aluminum-extrusion.html

[10] https://at-machining.com/aluminum-finishes/