Content Menu

● Introduction to Aluminum Extruders

>> Benefits of Upgraded Aluminum Extruders

● Real-World Examples and Case Studies

>> Compatibility and Installation

>>> Installation Steps:

● Filament Compatibility

● Cost and Long-Term Benefits

>> Reason Upgraded Aluminum Extruder

● Advanced Features and Customization

>> Direct Drive vs. Bowden Extruders

● Educational and Professional Applications

● Conclusion

● FAQ

>> 1. What are the main benefits of upgrading to an aluminum extruder?

>> 2. Is the upgraded aluminum extruder compatible with all 3D printers?

>> 3. Do I need to calibrate my extruder after upgrading?

>> 4. Can the upgraded aluminum extruder handle flexible filaments like TPU?

>> 5. Is it difficult to install the upgraded aluminum extruder?

● Citations:

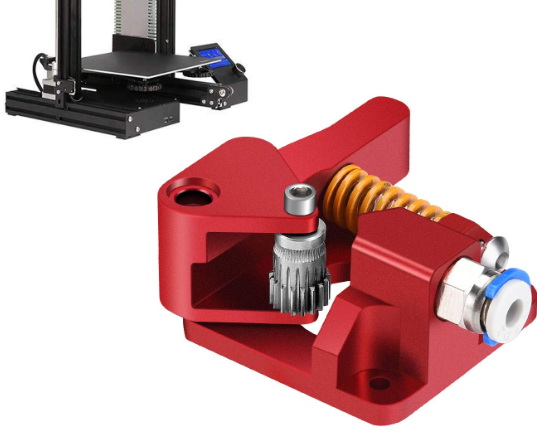

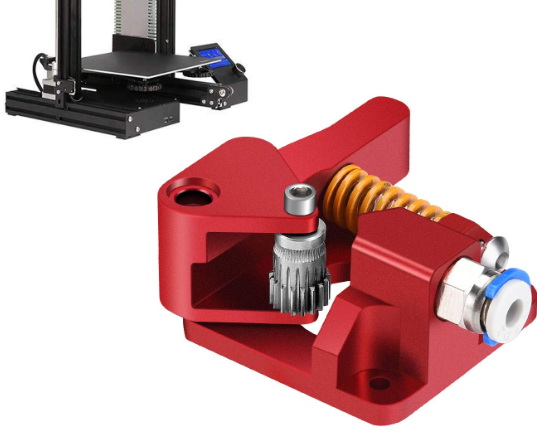

Upgrading to an aluminum extruder is a common practice among 3D printing enthusiasts seeking to enhance the performance and reliability of their printers. This upgrade offers several benefits over traditional plastic extruders, including improved durability, consistent filament feeding, and better handling of a wide range of filaments. In this article, we will delve into the reasons why upgrading to an aluminum extruder is a worthwhile investment for both beginners and experienced users.

Introduction to Aluminum Extruders

Aluminum extruders are designed to address the limitations of stock plastic extruders, which are prone to wear and tear, especially when used with abrasive or flexible filaments. The rigidity and durability of aluminum ensure consistent filament feeding, reducing the risk of slippage or jams, and thus improving print quality.

Benefits of Upgraded Aluminum Extruders

1. Enhanced Durability: Aluminum extruders are more robust than their plastic counterparts, resisting mechanical stress without cracking or warping. This ensures consistent performance over time and reduces the need for frequent replacements[1][2].

2. Improved Filament Control: The aggressive grip on the filament provided by metal gears minimizes slippage, leading to smoother feeding and more accurate prints. This is particularly beneficial for flexible filaments like TPU, which can be challenging to handle with stock extruders[1][3].

3. Higher Temperature Resistance: Aluminum can handle higher temperatures than plastic, making it suitable for printing with ABS, nylon, and other high-performance materials[1][3].

4. Precision Printing: Consistent filament flow and stable temperature control contribute to better layer adhesion, reduced stringing, and overall improved print quality[2][3].

5. Ease of Installation: Most aluminum extruder assemblies come as DIY kits that are easy to install, requiring minimal technical expertise[1][4].

Real-World Examples and Case Studies

Many users have reported significant improvements in print quality after upgrading to an aluminum extruder. For instance, one user noted that upgrading to a dual-gear metal extruder eliminated clicking and filament slippage, resulting in smoother and more consistent prints. Another user observed that the metal extruder handled flexible filaments much better than the stock plastic extruder, allowing them to print more complex and functional parts[4].

Compatibility and Installation

Aluminum extruders are compatible with many popular 3D printer models, such as the Ender 3 and CR-10 series. However, it's essential to check compatibility with your specific printer model before purchasing[2][4].

Installation Steps:

1. Preparation: Turn off and unplug your 3D printer. Remove any filament from the extruder.

2. Disassembly: Detach the Bowden tube from the stock extruder. Use an Allen wrench to remove the screws securing the stock extruder to the printer.

3. Component Removal: Carefully support the extruder motor as you remove the final screws.

4. Gear Installation: Slide the new steel gear onto the motor shaft, aligning the grub screw with the flat side of the shaft.

5. Assembly: Attach the metal extruder housing using the provided screws. Ensure the motor cable is correctly oriented.

6. Lever Arm: Assemble the lever arm with the idler pulley and attach it to the housing, ensuring it moves freely.

7. Spring Installation: Position the spring and secure it with the retaining screw. The lever arm should spring back into place when pressed.

8. Re-attach the Bowden Tube: Depending on the design, the coupler may be built into the extruder housing or may be a separate piece that is screwed in. In either case, push the PTFE inward until it won't move, and cannot be tugged back out.

9. Testing: Reconnect the wiring and power on the printer. Load filament and run a test print to ensure everything is functioning correctly.

10. Calibration: Calibrate the extruder by updating the printer's firmware settings to accommodate the new extruder specifications[4].

Filament Compatibility

Aluminum extruders support a wide range of filaments, including PLA, ABS, PETG, TPU (flexible), and specialty filaments that require higher temperatures. The following table compares filament compatibility between stock plastic extruders and upgraded aluminum extruders:

| Filament Type | Stock Plastic Extruder | Upgraded Aluminum Extruder |

| PLA | Excellent | Excellent |

| ABS | Good | Excellent |

| PETG | Good | Excellent |

| TPU (Flexible) | Poor | Good |

| Carbon Fiber Infused | Poor | Good |

| Nylon | Fair | Good |

Cost and Long-Term Benefits

The cost of an upgraded aluminum extruder typically ranges from $20 to $50, depending on the brand and features. While this may seem like an additional expense, it's important to consider the long-term benefits. The increased durability and improved print quality can save you money on filament and replacement parts in the long run[3][4].

Reason Upgraded Aluminum Extruder

Upgrading to an aluminum extruder is a worthwhile investment for several reasons:

- Durability: Aluminum extruders last longer than plastic ones, reducing maintenance costs.

- Consistent Filament Feeding: This leads to better print quality and fewer defects.

- Wide Filament Compatibility: Aluminum extruders can handle a variety of filaments, including flexible and high-temperature materials.

- Easy Installation: Most kits are designed for easy DIY installation.

Advanced Features and Customization

Some advanced aluminum extruder kits offer additional features such as dual-gear systems and adjustable tension mechanisms. These features enhance filament grip and allow for fine-tuning of the extrusion process, further improving print quality[4].

Direct Drive vs. Bowden Extruders

Aluminum extruders can be used in both direct drive and Bowden configurations. Direct drive extruders mount the motor directly above the hot end, providing better control over flexible filaments. Bowden extruders, on the other hand, reduce the weight on the moving print head, allowing for faster print speeds but may require more retraction tuning[2][4].

Educational and Professional Applications

Aluminum extruders are not only beneficial for hobbyists but also for educational and professional settings. Their reliability and ease of use make them ideal for environments where printers are frequently used. In educational settings, they provide a consistent learning experience, while in professional environments, they enhance productivity by reducing downtime and improving print quality[1].

Conclusion

Upgrading to an aluminum extruder is a significant step towards enhancing the performance and reliability of your 3D printer. With its improved durability, consistent filament feeding, and compatibility with a wide range of filaments, this upgrade offers long-term benefits that outweigh the initial costs. Whether you're a hobbyist or a professional, investing in an aluminum extruder can elevate your 3D printing experience.

FAQ

1. What are the main benefits of upgrading to an aluminum extruder?

Upgrading to an aluminum extruder offers several benefits, including enhanced durability, consistent filament feeding, improved print quality, and better handling of a wide range of filaments. Aluminum extruders are more robust and can withstand higher temperatures, making them ideal for printing with ABS, nylon, and other high-performance materials.

2. Is the upgraded aluminum extruder compatible with all 3D printers?

No, the compatibility of an upgraded aluminum extruder depends on the 3D printer model. Most kits are designed for popular models like the Ender 3 V2 and CR-10 series. Always check the product description to ensure compatibility before purchasing.

3. Do I need to calibrate my extruder after upgrading?

Yes, calibrating your extruder is essential after upgrading to ensure accurate filament extrusion and optimal print quality. This involves adjusting the E-steps value in your printer's firmware.

4. Can the upgraded aluminum extruder handle flexible filaments like TPU?

Yes, upgraded aluminum extruders are capable of handling flexible filaments like TPU much better than stock plastic extruders. The metal gears provide a reliable grip on the filament, minimizing slippage and ensuring smoother feeding.

5. Is it difficult to install the upgraded aluminum extruder?

No, installing an upgraded aluminum extruder is generally straightforward and can be completed in under an hour. Most kits include all necessary hardware and clear instructions for easy installation.

Citations:

[1] https://www.yjing-extrusion.com/why-upgrade-to-a-cr-10-aluminum-extruder-for-better-3d-printing.html

[2] https://www.yjing-extrusion.com/why-should-you-choose-an-aluminum-extruder-for-3d-printing.html

[3] https://www.yjing-extrusion.com/is-it-worth-buying-an-aluminum-extruder-for-my-3d-printer.html

[4] https://www.yjing-extrusion.com/is-the-upgraded-aluminum-extruder-v2-worth-the-investment-for-better-print-quality.html

[5] https://www.yjing-extrusion.com/how-to-install-an-aluminum-extruder-on-ender-3-v2.html

[6] https://www.yjing-extrusion.com/how-to-upgrade-your-3d-printer-with-an-aluminum-alloy-extruder.html

[7] https://www.goldapple-alu.com/the-cost-benefit-analysis-of-investing-in-extruded-aluminum-tubes-2.html

[8] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[9] https://www.yjing-extrusion.com/how-does-the-creality-mk8-aluminum-extruder-improve-filament-flow.html

[10] https://www.youtube.com/watch?v=3L3nPJZo04E

[11] https://hts-alu.com/fr/3d-printer-aluminum-extrusion/

[12] https://www.reddit.com/r/3Dprinting/comments/19au2rb/what_are_full_metal_extruders_and_what_are_their/

[13] https://www.solidprint3d.co.uk/prototyping-aluminium-extrusion-profiles-with-3d-printing/

[14] https://shop.machinemfg.com/aluminum-extrusions-applications-benefits-and-suitability/

[15] https://blog.goldsupplier.com/metal-extruder/

[16] https://www.yjing-extrusion.com/what-is-the-best-aluminum-extruder-for-high-quality-3d-printing.html