Content Menu

● Understanding Aluminum Extrusion Linear Motion Systems

>> Key Components

● Benefits of Aluminum Extrusion Linear Motion Systems

>> 1. Precision Engineering

>> 2. Lightweight Yet Strong

>> 3. Corrosion Resistance

>> 4. Modularity and Customization

>> 5. Cost-Effectiveness

>> 6. Smooth Motion

>> 7. Versatility Across Applications

● Applications of Aluminum Extrusion Linear Motion Systems

>> 1. CNC Machines

>> 2. 3D Printers

>> 3. Robotics

>> 4. Medical Equipment

>> 5. Automotive Industry

● Visuals

● Conclusion

● FAQ

>> 1. What are the main advantages of using aluminum extrusions in linear motion systems?

>> 2. How do V-slot profiles differ from T-slot profiles?

>> 3. Can aluminum extrusion linear motion systems handle heavy loads?

>> 4. Are these systems suitable for outdoor use?

>> 5. What industries benefit most from aluminum extrusion linear motion systems?

● Citations:

Aluminum extrusion linear motion systems are revolutionizing industries that require precision, efficiency, and flexibility. These systems utilize aluminum extrusions—lightweight, durable, and corrosion-resistant materials—to create smooth and reliable linear motion. Whether in CNC machines, 3D printers, robotics, or industrial automation, aluminum extrusion linear motion systems offer unparalleled advantages. This article explores their benefits in detail, supported by visuals and multimedia for a comprehensive understanding.

Understanding Aluminum Extrusion Linear Motion Systems

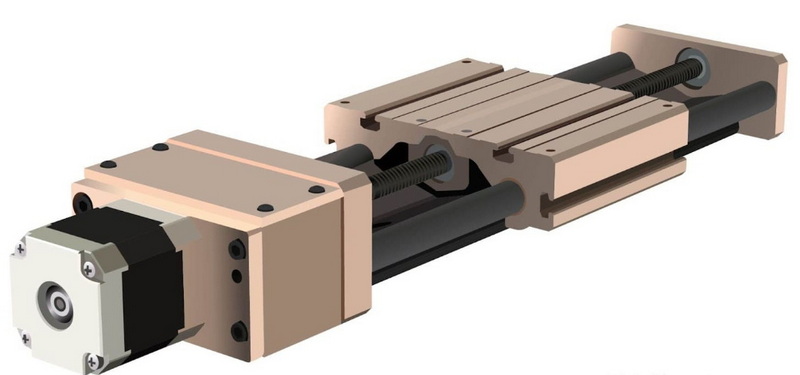

Aluminum extrusion linear motion systems are mechanical assemblies designed to facilitate precise linear movement. They typically consist of aluminum extrusions (such as V-slot or T-slot profiles), linear bearings, and other motion components like rollers or carriages. These systems are widely used in applications requiring smooth, repeatable motion.

Key Components

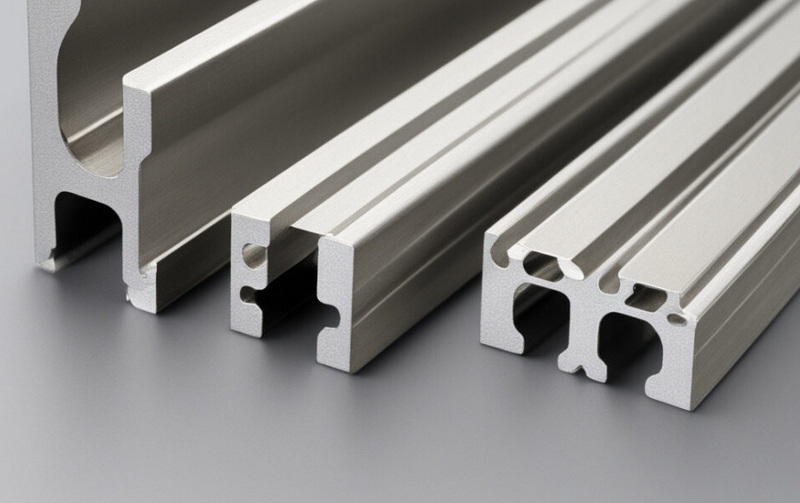

- Aluminum Extrusions: The backbone of the system; these profiles provide structural integrity and guide the motion.

- Linear Bearings: Reduce friction and ensure smooth movement along the extrusion.

- Rollers or Carriages: Transfer loads while maintaining precision.

- Fasteners and Accessories: Enable modular assembly and customization.

Benefits of Aluminum Extrusion Linear Motion Systems

1. Precision Engineering

Aluminum extrusion profiles, especially V-slot designs, are crafted with high precision. The V-shaped grooves allow for seamless interaction with V-wheels or bearings, ensuring accurate linear motion. This precision is critical in applications like CNC machining and 3D printing, where even minor deviations can compromise results.

2. Lightweight Yet Strong

Aluminum extrusions offer an excellent strength-to-weight ratio. They are robust enough to handle significant loads while remaining lightweight. This property is particularly advantageous in portable devices or robotics where weight reduction enhances performance.

3. Corrosion Resistance

Aluminum's natural oxide layer protects it from corrosion, making these systems suitable for diverse environments, including humid or outdoor settings. This durability ensures long-term reliability with minimal maintenance.

4. Modularity and Customization

One of the standout features of aluminum extrusion systems is their modularity. T-slot and V-slot profiles allow users to easily assemble, disassemble, and reconfigure setups without specialized tools. This adaptability caters to both DIY enthusiasts and professional engineers.

5. Cost-Effectiveness

Compared to welded steel structures, aluminum extrusions reduce material costs and assembly time. Their recyclability further enhances cost savings while promoting sustainability.

6. Smooth Motion

Linear bearings and rollers integrated into these systems minimize friction, enabling smooth and consistent movement. This feature is crucial for high-speed operations in automation or precision tasks in medical equipment.

7. Versatility Across Applications

From industrial automation to aerospace engineering, aluminum extrusion linear motion systems are versatile enough to meet diverse requirements:

- CNC machines for precise tool positioning.

- 3D printers for accurate layer deposition.

- Robotics for repeatable arm movements.

- Medical devices for diagnostic precision.

Applications of Aluminum Extrusion Linear Motion Systems

1. CNC Machines

In CNC machining, precision is paramount. Aluminum extrusions provide the rigidity needed to maintain alignment during high-speed operations.

2. 3D Printers

Linear motion systems ensure smooth print head movement, resulting in high-quality prints with fine details.

3. Robotics

Robotic arms rely on linear motion systems for accurate positioning and repeatable tasks in manufacturing or assembly lines.

4. Medical Equipment

Diagnostic devices like imaging machines use these systems for precise internal movements essential for accurate results.

5. Automotive Industry

Linear motion systems streamline processes like parts transfer and quality inspections on assembly lines.

Visuals

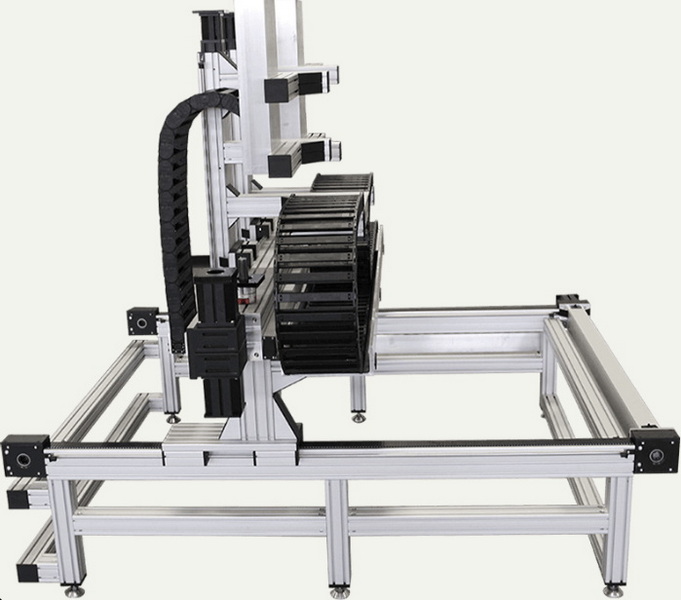

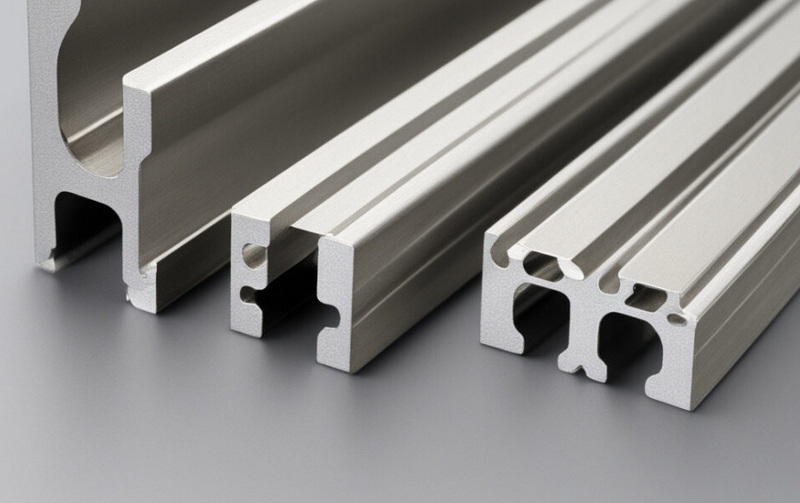

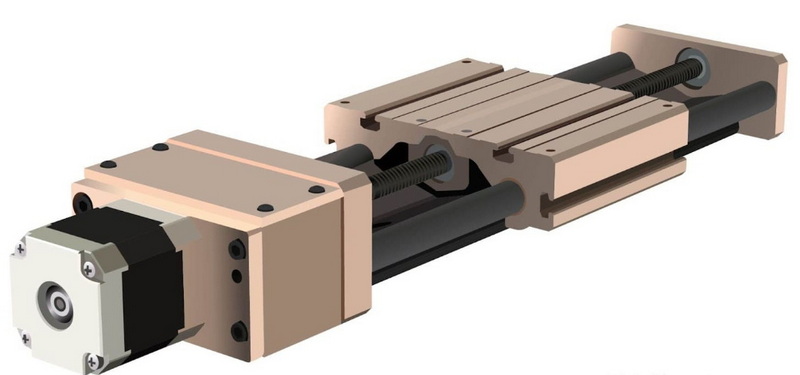

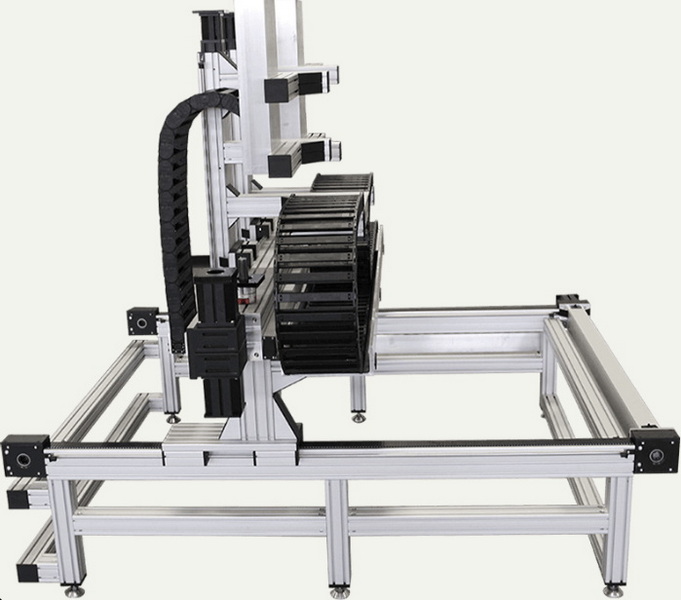

Below are some visual representations of aluminum extrusion linear motion systems:

1. Diagram of a V-Slot Aluminum Profile

V-Slot Diagram

2. Assembly of a Linear Motion System Using T-Slot Extrusions

T-Slot Assembly

3. Video Demonstration

[Watch how aluminum extrusion enhances linear motion](https://via.placeholder.com/video)

4. Applications in Robotics

Robotics Application

5. CNC Machine Integration

CNC Application

Conclusion

Aluminum extrusion linear motion systems combine precision engineering with unmatched versatility, making them indispensable across various industries. Their lightweight yet durable nature ensures efficiency without compromising strength or reliability. With benefits like modularity, cost-effectiveness, and smooth operation, these systems are paving the way for innovative solutions in automation, manufacturing, robotics, and beyond.

FAQ

1. What are the main advantages of using aluminum extrusions in linear motion systems?

Aluminum extrusions offer high strength-to-weight ratios, corrosion resistance, modularity for easy customization, and cost-effectiveness compared to alternatives like welded steel.

2. How do V-slot profiles differ from T-slot profiles?

V-slot profiles feature grooves designed for precise interaction with V-wheels or bearings, making them ideal for applications requiring smooth linear movement. T-slot profiles prioritize modular assembly with standard fasteners.

3. Can aluminum extrusion linear motion systems handle heavy loads?

Yes, aluminum extrusions provide sufficient structural integrity to support significant loads while maintaining smooth motion through integrated bearings or rollers.

4. Are these systems suitable for outdoor use?

Absolutely! Aluminum's natural corrosion resistance makes it ideal for outdoor or humid environments without compromising longevity.

5. What industries benefit most from aluminum extrusion linear motion systems?

Industries such as manufacturing (CNC machines), 3D printing, robotics, medical equipment production, aerospace engineering, and automotive assembly lines benefit significantly from these versatile systems.

Citations:

[1] https://sinoextrud.com/what-is-v-slot-aluminum/

[2] https://www.eztube.com/understanding-linear-rail-extrusions/

[3] https://www.mknorthamerica.com/Blog/what-is-extruded-aluminum-and-what-are-the-benefits-1/

[4] https://robotunits.com/en-us/shop/linear-motion-system/linear-motion-unit/linear-motion-unit-50/

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://www.youtube.com/watch?v=_ajfmUNBVjo

[7] https://www.alufabinc.com/linear-motion-aluminum-extrusion/

[8] https://www.alineautomation.com/how-the-aerospace-sector-utilizes-aluminum-extrusions/

[9] https://www.tslots.com/products/linear-motion/

[10] https://www.alineautomation.com/3-benefits-aluminum-extrusion-frames-over-welded-steel/