Content Menu

● The Aluminum Extrusion Process

● Key Benefits of Aluminum Extrusion in Portland OR

>> 1. Versatility and Design Flexibility

>> 2. Strength-to-Weight Ratio

>> 3. Corrosion Resistance

>> 4. Thermal and Electrical Conductivity

>> 5. Cost-Effectiveness

>> 6. Sustainability

>> 7. Customization Options

● Applications of Aluminum Extrusion in Portland OR

>> Construction and Architecture

>> Transportation

>> Industrial Machinery

>> Consumer Goods

>> Energy Sector

● The Aluminum Extrusion Industry in Portland OR

● Choosing the Right Aluminum Alloy

● The Future of Aluminum Extrusion in Portland OR

● Conclusion

● Frequently Asked Questions

>> 1. What are the typical lead times for custom aluminum extrusions in Portland OR?

>> 2. How does the cost of aluminum extrusion compare to other manufacturing methods?

>> 3. Can aluminum extrusions be welded or joined together?

>> 4. What are the environmental benefits of using aluminum extrusions in Portland OR?

>> 5. How can I ensure the quality of aluminum extrusions from Portland OR manufacturers?

● Citations:

Aluminum extrusion is a versatile manufacturing process that offers numerous advantages for businesses in Portland, Oregon, and beyond. This article will explore the many benefits of aluminum extrusion, its applications, and why it's a popular choice for various industries in the Pacific Northwest.

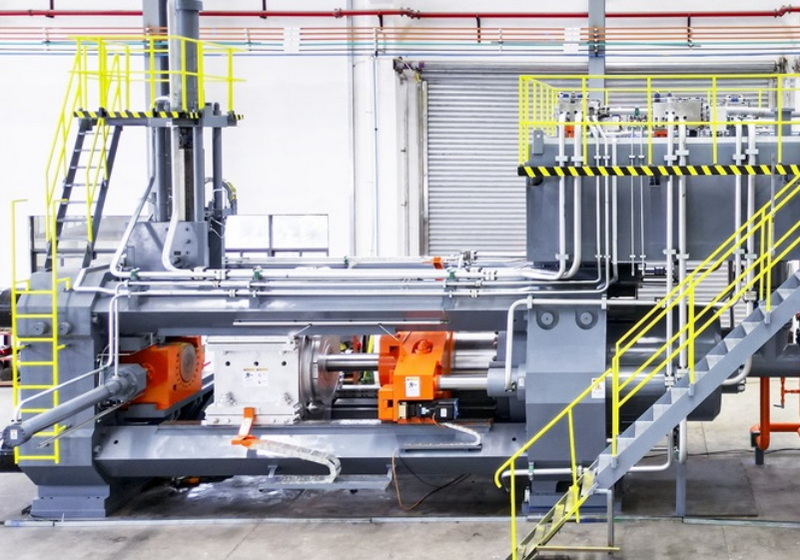

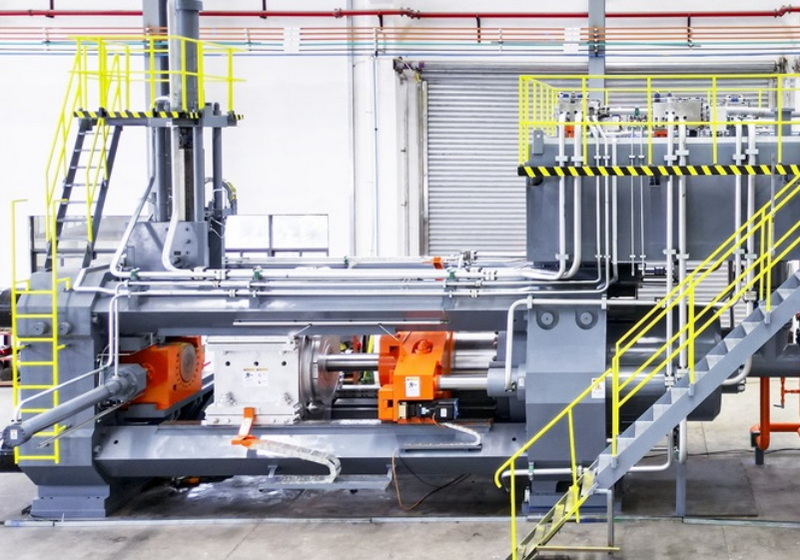

The Aluminum Extrusion Process

Before delving into the benefits, let's briefly review the aluminum extrusion process:

1. An aluminum billet is heated to 400-500°C[3].

2. The heated billet is placed in an extrusion press.

3. A powerful ram forces the aluminum through a die with a specific cross-sectional profile[3].

4. The extruded aluminum emerges from the die in the desired shape.

5. The extrusion is cooled, stretched, and cut to the required length[3].

Key Benefits of Aluminum Extrusion in Portland OR

1. Versatility and Design Flexibility

One of the primary advantages of aluminum extrusion in Portland OR is its incredible versatility. Manufacturers can create complex shapes and profiles that would be difficult or impossible to achieve with other manufacturing methods[1][2]. This flexibility allows designers to optimize their products for both form and function, incorporating features such as:

- Internal reinforcements

- Varying wall thicknesses

- Interlocking sections

- Screw bosses for easy assembly

2. Strength-to-Weight Ratio

Aluminum extrusions offer an excellent strength-to-weight ratio, making them ideal for applications where both strength and light weight are crucial[1][2]. This property is particularly beneficial in industries such as:

- Aerospace

- Automotive

- Construction

- Transportation

In Portland OR, where sustainability and efficiency are highly valued, the lightweight nature of aluminum extrusions can contribute to fuel savings and reduced carbon emissions in transportation applications.

3. Corrosion Resistance

The natural oxidation process of aluminum creates a protective layer that prevents rust and corrosion[1][2]. This makes aluminum extrusions an excellent choice for outdoor applications in Portland OR, where exposure to moisture and varying weather conditions is common. Additional treatments like anodizing can further enhance this corrosion resistance[4].

4. Thermal and Electrical Conductivity

Aluminum is an excellent conductor of both heat and electricity[1][2]. This property makes aluminum extrusions ideal for:

- Heat sinks in electronics

- Electrical connectors and bus bars

- Heat exchangers in HVAC systems

In Portland OR, where the tech industry is growing, these properties make aluminum extrusions a valuable material for various electronic applications.

5. Cost-Effectiveness

Aluminum extrusion can be a highly cost-effective manufacturing process, especially for medium to large production runs[2]. The ability to create complex shapes in a single process eliminates the need for additional assembly steps, reducing labor costs and production time. Moreover, the recyclability of aluminum contributes to long-term cost savings and sustainability[1].

6. Sustainability

Aluminum is 100% recyclable without loss of quality[1]. This aligns well with Portland OR's commitment to sustainability and environmental responsibility. The use of recycled aluminum in extrusions can significantly reduce energy consumption and carbon emissions compared to producing new aluminum.

7. Customization Options

Aluminum extrusions in Portland OR can be customized through various finishing processes to enhance their appearance and performance[4]. These include:

- Anodizing

- Powder coating

- Painting

- Brushing or polishing

This allows manufacturers to create products that not only perform well but also meet specific aesthetic requirements.

Applications of Aluminum Extrusion in Portland OR

The versatility of aluminum extrusion makes it suitable for a wide range of applications across various industries in Portland OR:

Construction and Architecture

- Window and door frames

- Curtain walls

- Structural components

- Solar panel frames

Transportation

- Automotive components

- Bicycle frames

- Truck and trailer parts

- Marine applications

Industrial Machinery

- Conveyor systems

- Workstations and assembly lines

- Safety guards and enclosures

Consumer Goods

- Furniture

- Appliances

- Sporting goods

Energy Sector

- Solar panel mounting systems

- Wind turbine components

- Heat exchangers for renewable energy systems

The Aluminum Extrusion Industry in Portland OR

Portland OR and the surrounding area are home to several aluminum extrusion facilities, including Hydro Extrusion's Portland facility[1]. These local manufacturers offer a range of services, including:

- Custom extrusion design

- Various extrusion press sizes to accommodate different profile sizes

- Value-added fabrication services

- Finishing options such as anodizing

The presence of these facilities in Portland OR provides local businesses with easy access to high-quality aluminum extrusions and expert support for their manufacturing needs.

Choosing the Right Aluminum Alloy

When working with aluminum extrusions in Portland OR, selecting the appropriate alloy is crucial. Some common alloys used in extrusions include:

- 6061: Offers good strength and corrosion resistance

- 6063: Provides excellent surface finish, ideal for architectural applications

- 7075: High-strength alloy often used in aerospace applications

The choice of alloy depends on the specific requirements of the application, such as strength, corrosion resistance, and formability[1].

The Future of Aluminum Extrusion in Portland OR

As industries in Portland OR continue to evolve and prioritize sustainability, the demand for aluminum extrusions is likely to grow. Emerging trends and opportunities include:

1. Increased use in electric vehicle manufacturing

2. Integration with 3D printing technologies for rapid prototyping

3. Development of new, high-performance aluminum alloys

4. Expansion of recycling programs to further reduce environmental impact

Conclusion

Aluminum extrusion offers numerous benefits for businesses in Portland OR, including design flexibility, strength-to-weight ratio, corrosion resistance, and sustainability. As industries in the region continue to innovate and grow, aluminum extrusions will play a crucial role in creating efficient, durable, and environmentally friendly products. By leveraging the expertise of local manufacturers and the inherent advantages of the extrusion process, companies in Portland OR can stay competitive and meet the evolving needs of their customers.

Frequently Asked Questions

1. What are the typical lead times for custom aluminum extrusions in Portland OR?

Lead times for custom aluminum extrusions in Portland OR can vary depending on the complexity of the design and the current production schedule. Generally, simple extrusions can be produced within 2-4 weeks, while more complex designs may take 4-6 weeks or longer. It's best to consult with local manufacturers for specific lead time estimates.

2. How does the cost of aluminum extrusion compare to other manufacturing methods?

Aluminum extrusion is often more cost-effective than other manufacturing methods, especially for medium to large production runs. While the initial tooling costs (die creation) can be significant, these costs are typically offset by the efficiency of the extrusion process and the reduction in secondary operations. For high-volume production, aluminum extrusion can be significantly less expensive than machining or casting.

3. Can aluminum extrusions be welded or joined together?

Yes, aluminum extrusions can be welded or joined using various methods. Common joining techniques include:

- Welding (MIG, TIG, or friction stir welding)

- Mechanical fasteners (bolts, screws, rivets)

- Adhesive bonding

- Specialized connectors designed for aluminum extrusions

The choice of joining method depends on the specific application, strength requirements, and aesthetic considerations.

4. What are the environmental benefits of using aluminum extrusions in Portland OR?

Aluminum extrusions offer several environmental benefits in Portland OR:

- 100% recyclability without loss of quality

- Reduced energy consumption when using recycled aluminum

- Lightweight nature contributes to fuel efficiency in transportation applications

- Durability and long lifespan reduce the need for frequent replacements

- Local production reduces transportation-related emissions

These factors align well with Portland's commitment to sustainability and environmental stewardship.

5. How can I ensure the quality of aluminum extrusions from Portland OR manufacturers?

To ensure the quality of aluminum extrusions from Portland OR manufacturers:

- Choose reputable manufacturers with proper certifications (e.g., ISO 9001)

- Request material certifications and test reports

- Discuss quality control processes and inspection methods

- Consider on-site visits to the manufacturing facility

- Start with small production runs to verify quality before scaling up

Many Portland OR manufacturers, such as Hydro Extrusion, have extensive quality control measures in place to ensure consistent, high-quality products[1].

Citations:

[1] https://www.hydro.com/profiles/custom-aluminum-extrusions-in-oregon

[2] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[3] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[4] https://dajcor.com/learning-centre/faq

[5] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[6] https://paramountextrusions.com/blogs/why-choose-custom-aluminum-extrusions

[7] https://aoptech.com/brands/t-slots/

[8] https://www.youtube.com/watch?v=Xh6NzqrGz94

[9] https://us.misumi-ec.com/maker/misumi/mech/product/al/faq/