Content Menu

● Understanding Aluminum Extrusion

● Key Benefits of Aluminum Extrusion

● Applications of Aluminum Extrusions in Phoenix AZ

● Local Manufacturers Leading the Charge

● Trends Shaping the Future of Aluminum Extrusion

● Challenges Facing Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What industries benefit most from aluminum extrusion?

>> 2. How does aluminum extrusion compare with other materials?

>> 3. Is aluminum extrusion environmentally friendly?

>> 4. What are common applications for aluminum extrusions?

>> 5. How do local manufacturers ensure quality in aluminum extrusion?

● Citations:

Aluminum extrusion is a manufacturing process that shapes aluminum alloy by forcing it through a die to create specific cross-sectional profiles. In Phoenix, Arizona, this technique has gained popularity across various industries due to its numerous advantages. This article will explore the benefits of aluminum extrusion, its applications, and how local manufacturers are leveraging this technology.

Understanding Aluminum Extrusion

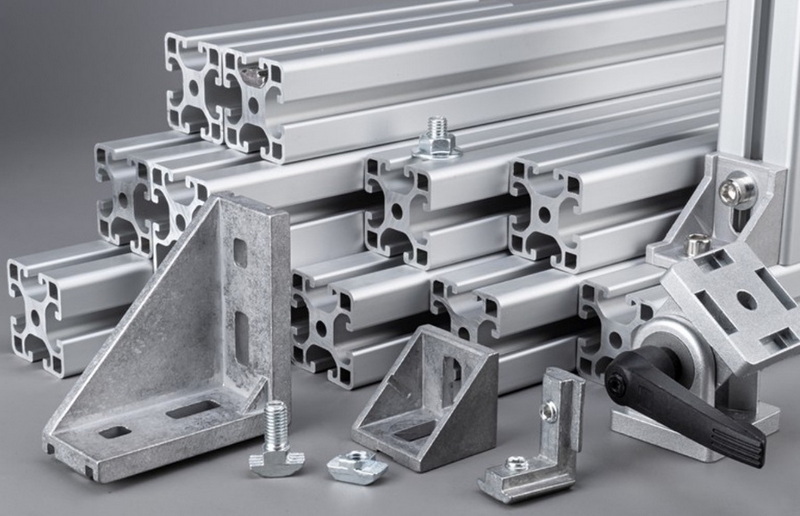

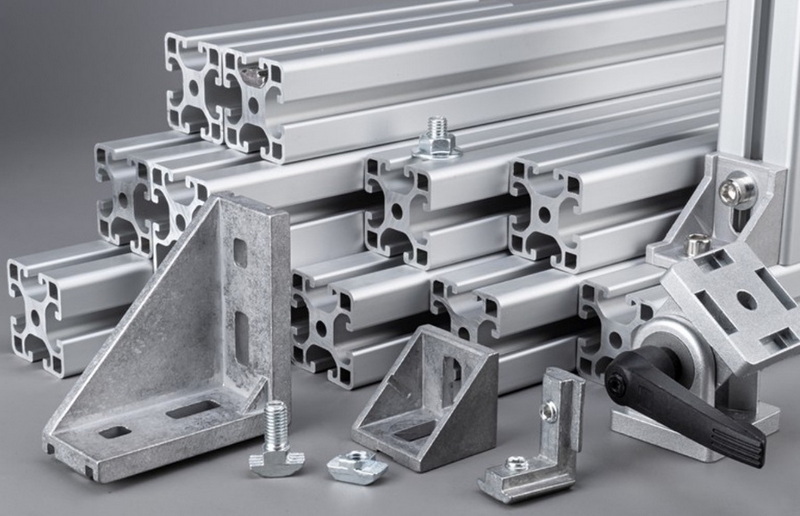

Aluminum extrusion can be likened to squeezing toothpaste from a tube. The aluminum is heated until it becomes malleable and then pushed through a die that shapes it into the desired form. This method allows for complex designs and precise dimensions, making it an ideal choice for innovative manufacturers in Phoenix.

The process begins with selecting the appropriate aluminum alloy, which can vary based on the intended application. Common alloys used in extrusion include 6061, 6063, and 6082, each offering different properties such as strength, corrosion resistance, and machinability. Once the alloy is chosen, it is heated to a specific temperature and then extruded through a die.

Key Benefits of Aluminum Extrusion

1. Cost-Effectiveness

- Aluminum extrusion is a cost-effective manufacturing process. It minimizes waste and reduces the need for secondary machining operations, which can be expensive and time-consuming. By creating parts directly from the extrusion process, companies can save significantly on production costs.

2. Lightweight Strength

- One of the most significant advantages of aluminum is its high strength-to-weight ratio. This characteristic is particularly beneficial in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. In Arizona's growing aerospace sector, lightweight materials are essential for innovation, making aluminum extrusions a preferred choice.

3. Corrosion Resistance

- Aluminum naturally forms a protective oxide layer that prevents corrosion. This feature is especially beneficial in Arizona's arid climate, where materials are often exposed to harsh environmental conditions. Structures made from aluminum extrusions require less maintenance and have a longer lifespan compared to those made from other materials like steel or iron.

4. Design Flexibility

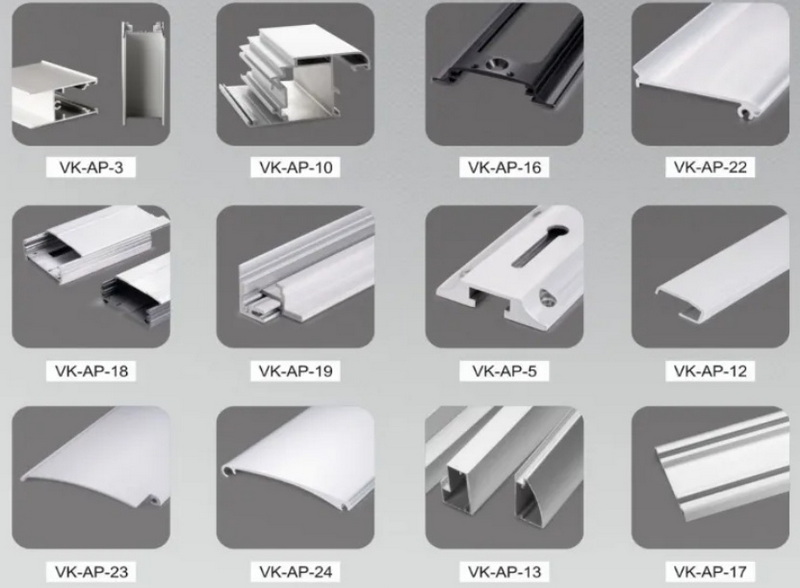

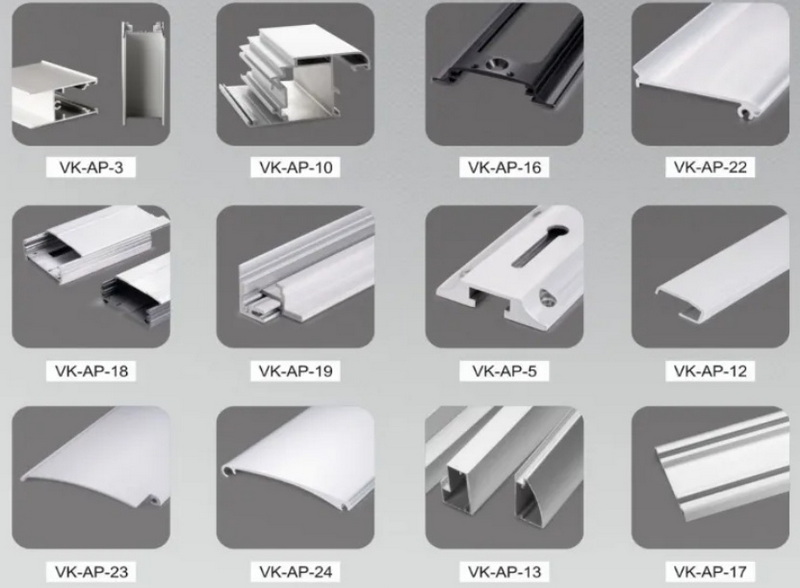

- The extrusion process allows for the creation of intricate shapes that would be difficult or impossible to achieve with other manufacturing methods. This design flexibility enables engineers and designers in Phoenix to push the boundaries of innovation in product development.

5. Sustainability

- Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice for manufacturers. In Arizona, where sustainability initiatives are increasingly prioritized, using recycled aluminum can enhance a company's green credentials.

6. Thermal Conductivity

- Aluminum has excellent thermal conductivity properties, making it ideal for applications requiring heat dissipation. This is particularly important in electronics and HVAC systems where managing heat effectively is crucial for performance and longevity.

7. Electrical Conductivity

- In addition to thermal conductivity, aluminum also boasts good electrical conductivity. This makes it suitable for electrical applications such as bus bars and electrical enclosures where efficient energy transfer is necessary.

8. Aesthetic Appeal

- Aluminum extrusions can be finished in various ways—anodizing, painting, or powder coating—which enhances their aesthetic appeal while providing additional protection against wear and corrosion. This versatility allows architects and designers to create visually appealing structures that stand out.

Applications of Aluminum Extrusions in Phoenix AZ

Aluminum extrusions find applications across various sectors in Phoenix:

- Construction: Used in window frames, doors, and structural components due to their durability and aesthetic appeal.

- Transportation: Lightweight components for vehicles and public transport systems contribute to improved fuel efficiency.

- Electronics: Heat sinks and enclosures benefit from aluminum's thermal conductivity while providing lightweight protection.

- Consumer Goods: Products ranging from furniture to appliances utilize aluminum extrusions for their modern look and functionality.

- Renewable Energy: Aluminum extrusions are used in solar panel frames and mounting systems due to their lightweight nature and resistance to corrosion.

- Medical Devices: The medical industry uses aluminum extrusions for various applications including medical equipment frames and components due to their strength, lightweight nature, and ease of sterilization.

- Furniture: Modern furniture designs often incorporate aluminum extrusions for legs, frames, or decorative elements because they allow for sleek designs without sacrificing stability.

Local Manufacturers Leading the Charge

Phoenix is home to several leading manufacturers specializing in aluminum extrusion. Companies like Zetwerk and APEL Extrusions have established state-of-the-art facilities that produce high-quality extruded products tailored to various industries.

Zetwerk operates advanced manufacturing lines equipped with cutting-edge technology that ensures precision and quality control throughout the production process. Their commitment to innovation sets them apart in the competitive landscape.

APEL Extrusions focuses on providing custom solutions tailored specifically to client needs. Their expertise in developing unique profiles allows them to serve diverse markets effectively while maintaining high standards of service.

Trends Shaping the Future of Aluminum Extrusion

As industries evolve and new technologies emerge, the demand for aluminum extrusions is expected to grow. Local manufacturers are investing in advanced equipment and processes to meet this demand while maintaining high standards of quality and sustainability.

Some trends shaping the future include:

- Increased Automation: Manufacturers are integrating automation into their processes to enhance efficiency. Automated systems reduce human error and increase production rates while maintaining quality control.

- Advanced Alloys: Research into new aluminum alloys with improved properties will expand application possibilities. These alloys may offer enhanced strength or corrosion resistance tailored for specific environments or uses.

- Customization: As industries seek tailored solutions, manufacturers will focus on providing highly customized products that meet specific requirements without compromising on quality or performance.

- Sustainable Practices: Continued emphasis on sustainability will drive innovations in recycling processes. Manufacturers are exploring ways to reduce energy consumption during production while maximizing material reuse.

- Digital Integration: The rise of Industry 4.0 technologies means more manufacturers are adopting digital tools for better tracking of production processes—from design through delivery—allowing for greater transparency and efficiency.

Challenges Facing Aluminum Extrusion

While there are many benefits associated with aluminum extrusion, there are also challenges that manufacturers face:

- Market Competition: With increasing demand comes heightened competition among manufacturers not just locally but globally as well.

- Material Costs: Fluctuations in raw material costs can impact pricing strategies for manufacturers.

- Technological Adaptation: Keeping up with technological advancements requires ongoing investment which may pose financial challenges for smaller companies.

- Regulatory Compliance: Adhering to environmental regulations regarding emissions and waste management can be complex but necessary for sustainable operations.

Conclusion

In summary, aluminum extrusion offers numerous benefits that make it an attractive option for manufacturers in Phoenix AZ. From cost-effectiveness and lightweight strength to corrosion resistance and design flexibility, the advantages are clear. As local companies continue to innovate while prioritizing sustainability, the future looks bright for aluminum extrusion in Arizona.

FAQ

1. What industries benefit most from aluminum extrusion?

Aluminum extrusion benefits various industries including construction, transportation, electronics, consumer goods, renewable energy, medical devices, and furniture due to its versatility and strength.

2. How does aluminum extrusion compare with other materials?

Aluminum offers a superior strength-to-weight ratio compared to steel or plastic, making it ideal for applications requiring lightweight yet strong materials.

3. Is aluminum extrusion environmentally friendly?

Yes, aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice for manufacturers focused on sustainability.

4. What are common applications for aluminum extrusions?

Common applications include window frames, vehicle components, heat sinks for electronics, furniture parts, solar panel frames, medical equipment frames, and decorative elements.

5. How do local manufacturers ensure quality in aluminum extrusion?

Local manufacturers implement stringent quality control measures throughout the production process including custom gauging and adherence to industry standards while utilizing advanced technology for precision manufacturing.

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-benefits-of-aluminum-extrusion-in-arizona.html

[2] https://aluminumextrusions.net/usa/arizona/

[3] https://kundel.com/blog/some-interesting-facts-about-using-aluminum-extrusion/

[4] https://profileprecisionextrusions.com/aluminum-extrusion-manufacturing-process/

[5] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[6] https://profileprecisionextrusions.com/benefits/

[7] https://dajcor.com/learning-centre/faq

[8] https://www.industrialmetalsupply.com/custom-extrusions

[9] https://unitedalum.com/com-extrusion.htm