Content Menu

● The Aluminum Extrusion Process

● Benefits of Aluminum Extrusion in Malaysia

>> 1. Versatility and Customization

>> 2. Cost-Effectiveness

>> 3. Lightweight Yet Strong

>> 4. Corrosion Resistance

>> 5. Excellent Thermal and Electrical Conductivity

>> 6. Sustainability and Recyclability

>> 7. Aesthetic Appeal

>> 8. Rapid Production and Prototyping

>> 9. Precision and Consistency

>> 10. Versatile Joining Methods

● Applications of Aluminum Extrusion in Malaysia

>> Construction Industry

>> Automotive Sector

>> Electronics and Electrical

>> Furniture and Interior Design

>> Transportation

● The Future of Aluminum Extrusion in Malaysia

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main industries that benefit from aluminum extrusion in Malaysia?

>> 2. How does aluminum extrusion contribute to sustainability in Malaysian manufacturing?

>> 3. What are the cost advantages of using aluminum extrusions in Malaysian industries?

>> 4. How does the Malaysian climate affect the performance of aluminum extrusions?

>> 5. What future developments can we expect in the aluminum extrusion industry in Malaysia?

● Citations:

Aluminum extrusion has become an integral part of various industries in Malaysia, offering numerous advantages that have propelled its popularity in recent years. This article will explore the multifaceted benefits of aluminum extrusion in Malaysia, shedding light on why it has become a preferred choice for manufacturers and businesses across the country.

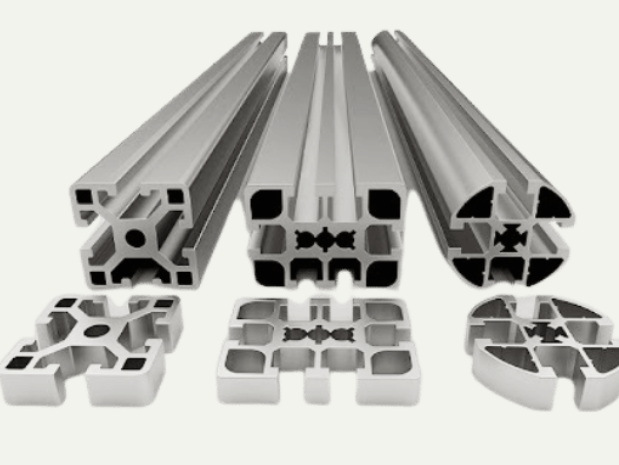

The Aluminum Extrusion Process

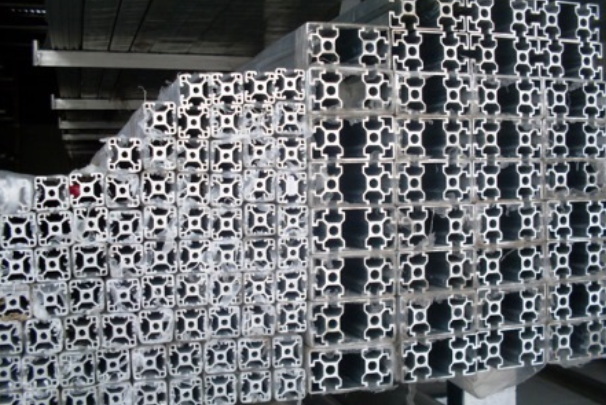

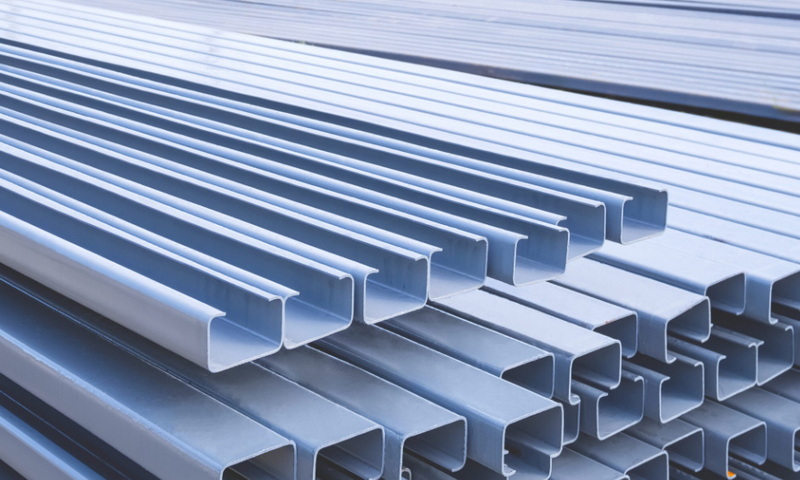

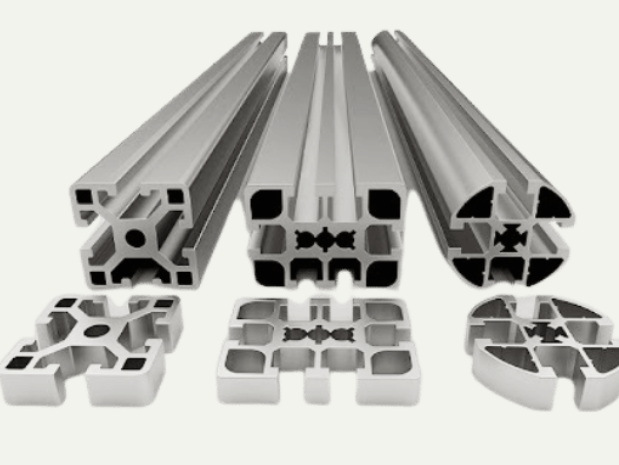

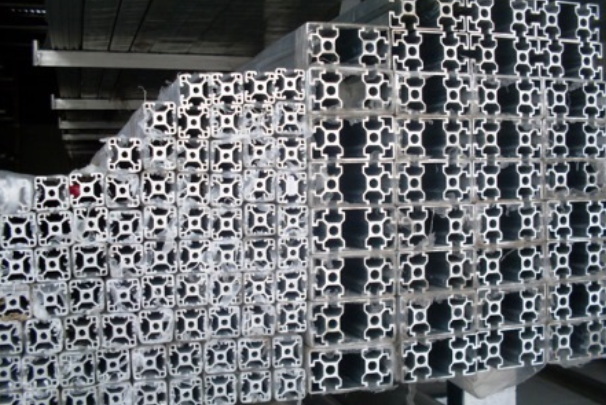

Before delving into the benefits, it's essential to understand the aluminum extrusion process. Aluminum extrusion involves forcing heated aluminum billets through a die with a specific cross-sectional profile. This process results in a long, straight piece of aluminum with a consistent cross-section that matches the die's shape.

The process can be broken down into several steps:

1. Die preparation and preheating

2. Aluminum billet preheating

3. Billet transfer to the extrusion press

4. Ram pushing the billet into the container

5. Extruded material emerging through the die

6. Extrusion guidance along the runout table and quenching

7. Shearing to table length

8. Cooling to room temperature

9. Stretching into alignment

10. Cutting to final length

Benefits of Aluminum Extrusion in Malaysia

1. Versatility and Customization

One of the primary benefits of aluminum extrusion in Malaysia is its incredible versatility. Manufacturers can create a wide range of profiles and shapes to suit various applications across different industries. This flexibility allows for customized solutions that meet specific design requirements, whether for construction, automotive, or consumer goods sectors.

2. Cost-Effectiveness

Aluminum extrusion is a cost-effective manufacturing process, especially for medium to large production runs. The initial tooling costs are relatively low compared to other manufacturing methods, and the process itself is efficient, reducing overall production expenses. This cost-effectiveness makes aluminum extrusion malaysia an attractive option for businesses looking to optimize their manufacturing costs.

3. Lightweight Yet Strong

Aluminum extrusions offer an excellent strength-to-weight ratio, making them ideal for applications where weight reduction is crucial without compromising structural integrity. This property is particularly beneficial in the automotive and aerospace industries, where lighter components contribute to improved fuel efficiency and performance.

4. Corrosion Resistance

In Malaysia's tropical climate, corrosion resistance is a valuable property. Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This characteristic ensures that aluminum extrusions maintain their appearance and structural integrity over time, even in challenging environmental conditions.

5. Excellent Thermal and Electrical Conductivity

Aluminum is an excellent conductor of heat and electricity, making it suitable for various applications in the electrical and energy sectors. In Malaysia, where energy efficiency is becoming increasingly important, aluminum extrusions are used in heat sinks, solar panel frames, and electrical enclosures.

6. Sustainability and Recyclability

As environmental concerns grow, the sustainability of materials becomes crucial. Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice. This recyclability aligns with Malaysia's efforts to promote sustainable manufacturing practices and reduce environmental impact.

7. Aesthetic Appeal

Aluminum extrusions can be finished in various ways, including anodizing, powder coating, and painting. This versatility in finishing options allows for a wide range of aesthetic possibilities, making aluminum extrusions suitable for both functional and decorative applications in architecture and interior design.

8. Rapid Production and Prototyping

The aluminum extrusion process is relatively quick, allowing for rapid production of components. This speed is particularly beneficial for businesses that need to respond quickly to market demands or prototype new designs. The efficiency of aluminum extrusion malaysia contributes to shorter lead times and increased productivity.

9. Precision and Consistency

Modern aluminum extrusion techniques ensure high precision and consistency in the final products. This level of accuracy is crucial for industries that require tight tolerances, such as aerospace and electronics. The consistency in quality also reduces waste and improves overall manufacturing efficiency.

10. Versatile Joining Methods

Aluminum extrusions can be easily joined using various methods, including welding, adhesive bonding, and mechanical fastening. This versatility in joining techniques allows for the creation of complex structures and assemblies, expanding the potential applications of aluminum extrusions in Malaysia's manufacturing sector.

Applications of Aluminum Extrusion in Malaysia

Construction Industry

The construction sector in Malaysia has embraced aluminum extrusions for various applications, including:

- Window and door frames

- Curtain walls

- Structural components

- Railings and balustrades

- Roofing systems

Automotive Sector

In the automotive industry, aluminum extrusions are used for:

- Body frames

- Bumper reinforcements

- Heat exchangers

- Suspension components

- Interior trim

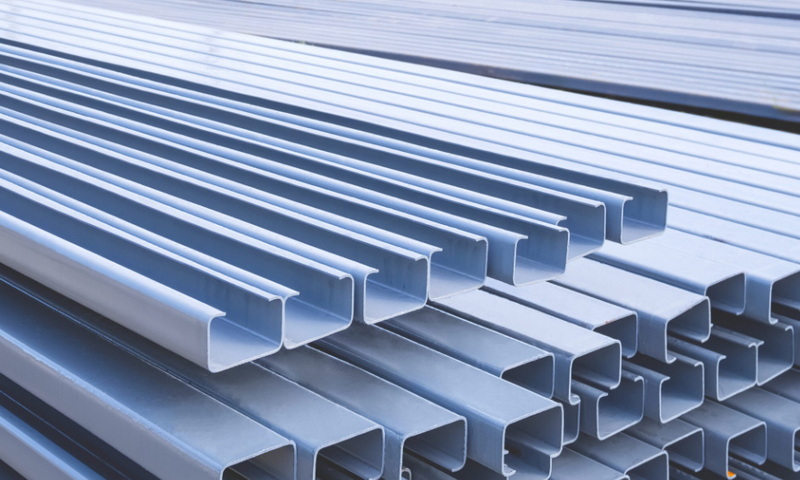

Electronics and Electrical

The electronics and electrical sectors utilize aluminum extrusions for:

- Heat sinks

- LED lighting housings

- Enclosures for electronic devices

- Solar panel frames

- Cable trays and conduits

Furniture and Interior Design

Aluminum extrusions find applications in furniture and interior design, such as:

- Table and chair frames

- Shelving systems

- Partition walls

- Decorative elements

- Display stands

Transportation

Beyond automotive, aluminum extrusions are used in other transportation sectors:

- Railway car bodies

- Marine vessel components

- Bicycle frames

- Aerospace structural components

The Future of Aluminum Extrusion in Malaysia

The aluminum extrusion industry in Malaysia is poised for significant growth in the coming years. Factors contributing to this growth include:

1. Increasing demand from the construction and automotive sectors

2. Government initiatives promoting sustainable and energy-efficient materials

3. Growing awareness of the benefits of aluminum extrusions among manufacturers

4. Technological advancements in extrusion processes and alloy development

As Malaysia continues to develop its manufacturing capabilities, aluminum extrusion is expected to play an increasingly important role in various industries. The versatility, cost-effectiveness, and sustainability of aluminum extrusions align well with Malaysia's economic and environmental goals.

Conclusion

The benefits of aluminum extrusion in Malaysia are numerous and far-reaching. From its versatility and cost-effectiveness to its sustainability and aesthetic appeal, aluminum extrusion offers solutions to many of the challenges faced by modern industries. As Malaysia continues to grow and innovate, the aluminum extrusion industry is well-positioned to support this progress, providing high-quality, customizable, and sustainable components for a wide range of applications.

The future of aluminum extrusion malaysia looks bright, with ongoing technological advancements and increasing demand across various sectors. By leveraging these benefits, Malaysian businesses can enhance their competitiveness, improve product quality, and contribute to the country's economic growth while adhering to sustainable practices.

Frequently Asked Questions (FAQ)

1. What are the main industries that benefit from aluminum extrusion in Malaysia?

The main industries benefiting from aluminum extrusion in Malaysia include construction, automotive, electronics, furniture, and transportation. These sectors leverage the versatility, strength, and lightweight properties of aluminum extrusions for various applications, from building facades to automotive components and electronic enclosures.

2. How does aluminum extrusion contribute to sustainability in Malaysian manufacturing?

Aluminum extrusion contributes to sustainability in Malaysian manufacturing through its 100% recyclability without loss of properties. This characteristic reduces waste and energy consumption in production. Additionally, the lightweight nature of aluminum extrusions helps create more energy-efficient products, particularly in the automotive and construction industries.

3. What are the cost advantages of using aluminum extrusions in Malaysian industries?

The cost advantages of using aluminum extrusions in Malaysian industries include lower initial tooling costs compared to other manufacturing methods, efficient production processes that reduce overall expenses, and the material's durability, which leads to lower maintenance costs over time. Furthermore, the lightweight nature of aluminum can result in reduced transportation costs for finished products.

4. How does the Malaysian climate affect the performance of aluminum extrusions?

The Malaysian climate, characterized by high humidity and temperatures, actually showcases the benefits of aluminum extrusions. The natural corrosion resistance of aluminum makes it ideal for use in tropical environments. The protective oxide layer that forms on aluminum surfaces helps maintain the material's appearance and structural integrity, even in challenging weather conditions.

5. What future developments can we expect in the aluminum extrusion industry in Malaysia?

Future developments in the aluminum extrusion industry in Malaysia may include advancements in alloy technology to create even stronger and lighter materials, improvements in extrusion processes for greater precision and efficiency, and increased adoption of automation and smart manufacturing techniques. We can also expect to see a growing focus on sustainable practices and the development of new applications for aluminum extrusions in emerging industries.

Citations:

[1] https://www.alumac.my/blog/leading-aluminium-extrusion-profile-supplier-in-malaysia/

[2] https://www.grandviewresearch.com/industry-analysis/asia-pacific-aluminum-extrusion-market-report

[3] https://www.linkedin.com/pulse/benefits-aluminum-extrusions-eaglealuminum-ixbvc

[4] https://newagealuminium.com

[5] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[6] https://www.alcircle.com/news/top-five-aluminium-extrusion-companies-in-malaysia-28230

[7] https://www.alumac.my/blog/the-benefits-of-using-aluminium-fabrication-services-for-precision-cutting-in-malaysia/

[8] https://www.youtube.com/watch?v=iiGlq7408ME

[9] https://recoda.gov.my/priority-industries/aluminium-industry/

[10] https://www.linkedin.com/pulse/malaysia-aluminum-alloy-extrusions-extruded-products-womee/