Content Menu

● Understanding Aluminum Extrusion

● Key Benefits of Aluminum Extrusion in Denver

● Applications of Aluminum Extrusion

● Cost Efficiency

● Aluminum Extrusion Process Overview

● Environmental Impact

● Innovative Uses of Aluminum Extrusion

● Challenges Faced by Aluminum Extrusion Industry

● Conclusion

● Frequently Asked Questions

>> 1. What industries benefit most from aluminum extrusion in Denver?

>> 2. How does aluminum compare to other materials like steel?

>> 3. Can aluminum extrusions be customized for specific projects?

>> 4. What environmental benefits does aluminum extrusion offer?

>> 5. How does the cost of aluminum extrusion affect project budgets?

Aluminum extrusion has become an essential process in various industries, including construction, automotive, aerospace, and more. In Denver, the advantages of aluminum extrusion are particularly pronounced due to the region's unique demands and environmental conditions. This article explores the numerous benefits of aluminum extrusion, specifically in the Denver area, highlighting its applications, efficiency, and sustainability.

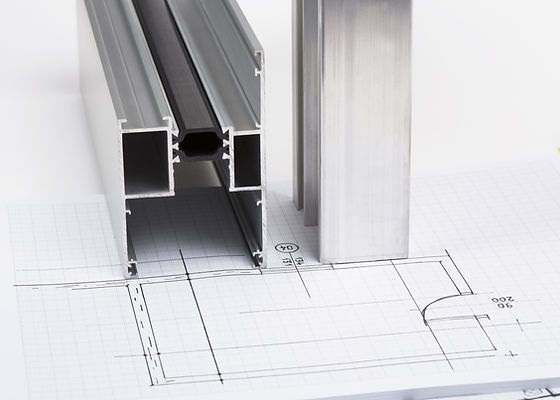

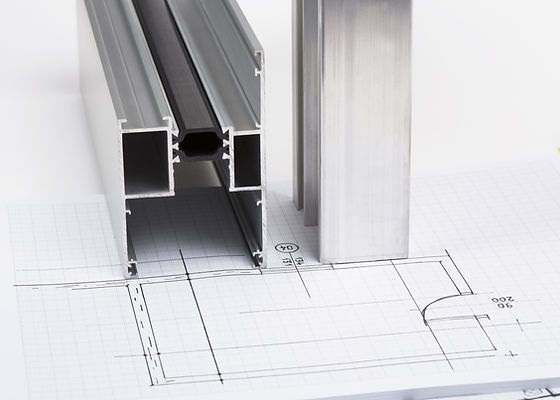

Understanding Aluminum Extrusion

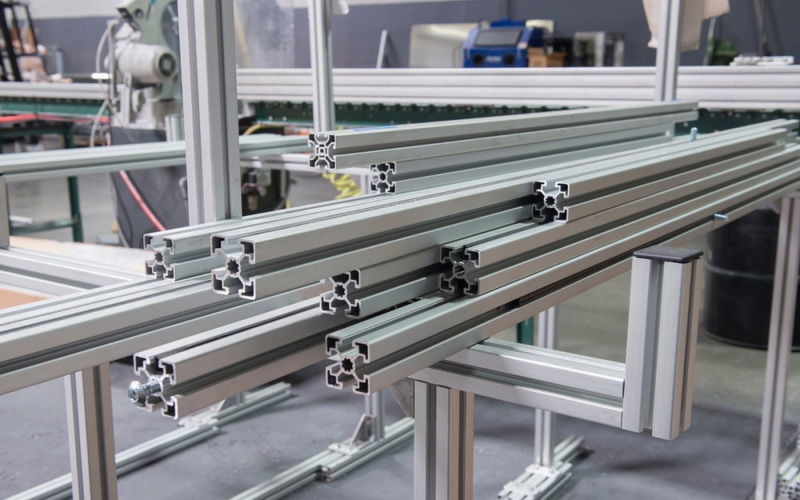

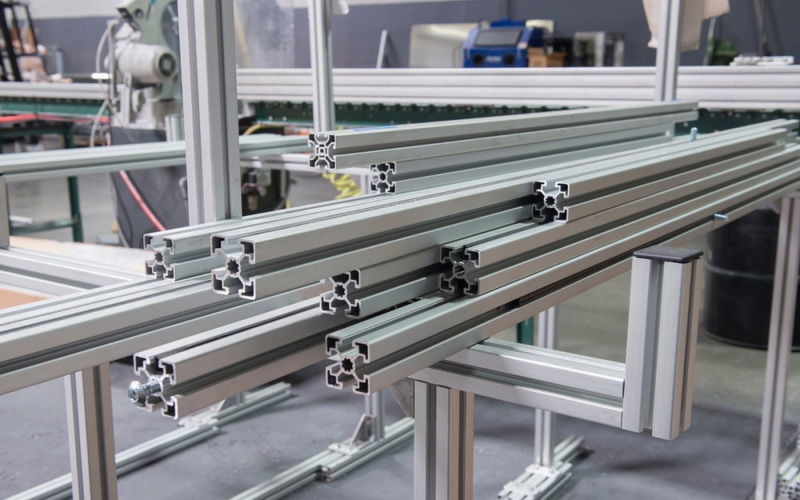

Aluminum extrusion is a manufacturing process that involves forcing aluminum alloy through a die to create specific shapes and profiles. This method allows for the production of complex shapes that are lightweight yet strong, making aluminum extrusions ideal for a wide range of applications.

The process begins with a solid cylindrical piece of aluminum known as a billet. The billet is heated to a malleable state before being pushed through a die that shapes it into the desired profile. Once extruded, the aluminum can be cut to length and further processed through various finishing techniques such as anodizing or powder coating.

Key Benefits of Aluminum Extrusion in Denver

- Lightweight Properties: Aluminum is approximately one-third the weight of steel. This lightweight nature reduces transportation costs and makes handling easier during construction projects.

- Strength and Durability: Despite its light weight, aluminum is incredibly strong. It can be engineered to meet specific strength requirements by varying its alloy composition and extrusion design.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion. This property is particularly beneficial in Denver's varied climate, where moisture levels can fluctuate significantly.

- Design Flexibility: The extrusion process allows for a high degree of customization. Manufacturers can create intricate designs tailored to specific project needs without significant increases in cost.

- Sustainability: Aluminum is 100% recyclable without losing its properties. This makes it an environmentally friendly choice for construction and manufacturing projects in Denver.

Applications of Aluminum Extrusion

In Denver, aluminum extrusions are used across various sectors:

- Construction: Used for window frames, curtain walls, and structural components due to their strength and aesthetic appeal. The ability to create custom profiles means architects can design buildings that are both functional and visually striking.

- Transportation: Lightweight aluminum extrusions are utilized in automotive parts and public transport vehicles, enhancing fuel efficiency. For example, bus frames made from aluminum can reduce overall vehicle weight, leading to lower fuel consumption.

- Aerospace: The aerospace industry benefits from aluminum's strength-to-weight ratio, making it ideal for aircraft components. Components such as wing structures and fuselage frames often utilize aluminum extrusions to optimize performance while minimizing weight.

- Electronics: Aluminum extrusions serve as heat sinks and housings in electronic devices due to their excellent thermal conductivity. This property helps dissipate heat effectively, ensuring electronic components operate within safe temperature ranges.

Cost Efficiency

While the initial cost of aluminum extrusion may be higher than other materials like steel, the long-term savings often outweigh these upfront expenses. Factors contributing to this include:

- Lower Maintenance Costs: Due to its corrosion resistance, aluminum requires less maintenance over its lifespan compared to steel. This is particularly relevant in environments like Denver where weather conditions can cause wear on materials.

- Recyclability: At the end of its life cycle, aluminum can be recycled into new products at a fraction of the energy cost required to produce new aluminum from ore. This not only conserves resources but also reduces landfill waste.

- Reduced Weight: The lighter weight of aluminum reduces shipping costs and allows for smaller cranes during installation, further lowering project costs. This aspect is crucial in urban areas like Denver where space constraints may limit equipment options.

Aluminum Extrusion Process Overview

The aluminum extrusion process involves several key steps:

1. Billet Preparation: A solid cylindrical piece of aluminum (billet) is heated to around 900°F.

2. Extrusion: The heated billet is placed into a press where it is forced through a die to create the desired shape.

3. Cooling: The extruded shape is cooled using air or water quenching techniques.

4. Cutting and Finishing: Once cooled, the extruded profiles are cut to length and may undergo additional finishing processes such as anodizing or painting.

This process allows for rapid production of high-quality components tailored to specific requirements.

Environmental Impact

Aluminum extrusion aligns well with sustainability goals due to:

- Energy Efficiency: The recycling process for aluminum uses only 5% of the energy needed to produce new aluminum from ore. This significant reduction in energy consumption contributes positively to environmental conservation efforts.

- Sustainable Practices: Many manufacturers in Denver are adopting green practices in their production processes, further reducing their carbon footprint. These practices include using renewable energy sources during manufacturing and implementing waste reduction strategies.

- Longevity: The durability of aluminum means that products made from it have longer lifespans compared to those made from other materials. This longevity reduces the need for frequent replacements, contributing to lower overall resource consumption over time.

Innovative Uses of Aluminum Extrusion

In addition to traditional applications, innovative uses for aluminum extrusion continue to emerge:

- Solar Panel Frames: With the growing emphasis on renewable energy sources in Denver's eco-conscious market, aluminum extrusions are increasingly used for solar panel mounting systems due to their lightweight nature and resistance to corrosion.

- Furniture Design: Modern furniture designers are incorporating aluminum extrusions into their creations for both aesthetic appeal and structural integrity. The sleek lines and customizable shapes allow designers to push creative boundaries while maintaining functionality.

- Bicycle Frames: The cycling community in Denver benefits from lightweight yet durable bicycle frames made from aluminum extrusions. These frames provide cyclists with improved performance without sacrificing strength or safety.

Challenges Faced by Aluminum Extrusion Industry

Despite its many benefits, the aluminum extrusion industry faces several challenges:

- Market Competition: Increased competition from alternative materials such as plastics and composites can impact market share for aluminum products. Manufacturers must continually innovate to maintain relevance.

- Supply Chain Issues: Fluctuations in raw material prices can affect production costs and timelines. Establishing reliable supply chains is crucial for manufacturers operating in Denver's dynamic market environment.

- Technological Advancements: Keeping pace with technological advancements requires ongoing investment in equipment and training. Companies must adapt quickly to incorporate new technologies that improve efficiency and product quality.

Conclusion

Aluminum extrusion offers numerous benefits that make it an ideal choice for many applications in Denver. Its lightweight yet strong properties, combined with corrosion resistance and design flexibility, position it as a leading material in various industries. Additionally, its sustainability credentials further enhance its appeal as businesses increasingly prioritize eco-friendly practices. As industries continue to seek efficient solutions that meet both performance standards and environmental considerations, aluminum extrusion will undoubtedly play a pivotal role in shaping the future of manufacturing and construction in Denver.

Frequently Asked Questions

1. What industries benefit most from aluminum extrusion in Denver?

Aluminum extrusion is widely used in construction, transportation, aerospace, electronics, renewable energy sectors like solar panel manufacturing, and even furniture design due to its lightweight strength and versatility.

2. How does aluminum compare to other materials like steel?

While steel may have a lower initial cost, aluminum offers superior corrosion resistance and lower maintenance costs over time, making it more cost-effective in the long run especially under varying environmental conditions like those found in Denver.

3. Can aluminum extrusions be customized for specific projects?

Yes! The extrusion process allows manufacturers to create custom shapes tailored to meet specific design requirements without significant cost increases or delays compared to traditional manufacturing methods.

4. What environmental benefits does aluminum extrusion offer?

Aluminum is fully recyclable without loss of properties; this significantly reduces energy consumption compared to producing new aluminum from raw materials while also minimizing landfill waste through recycling initiatives.

5. How does the cost of aluminum extrusion affect project budgets?

Although initial costs may be higher than other materials like steel or plastic composites, savings from reduced maintenance needs and transportation costs can make aluminum extrusions more economical over time while also enhancing overall project sustainability efforts.