Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process

● Benefits of Aluminum Extrusion

● Applications of Aluminum Extrusion in Arizona

>> Case Study: Solar Energy Applications

● Local Manufacturers Leading the Charge

>> APEL Extrusions Facility

● The Future of Aluminum Extrusion in Arizona

>> Emerging Trends

● Conclusion

● FAQ

>> 1. What industries benefit most from aluminum extrusion?

>> 2. How does aluminum extrusion compare to other manufacturing processes?

>> 3. Is aluminum extrusion environmentally friendly?

>> 4. What are some common applications of aluminum extrusions?

>> 5. How do local manufacturers ensure quality in aluminum extrusion?

Aluminum extrusion is a versatile manufacturing process that involves shaping aluminum alloy by forcing it through a die to create a specific cross-sectional profile. This method has gained significant traction in Arizona, where the demand for lightweight, durable materials is on the rise. In this article, we will explore the numerous benefits of aluminum extrusion in Arizona, its applications across various industries, and how local manufacturers are leveraging this technology to meet market needs.

Understanding Aluminum Extrusion

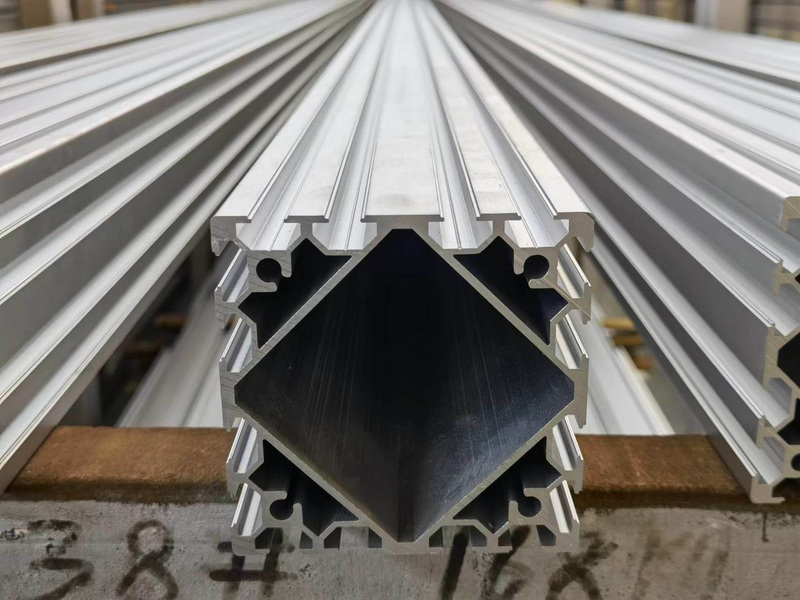

Aluminum extrusion is akin to squeezing toothpaste from a tube; the aluminum is heated until malleable and then pushed through a die to form shapes that can be used in a myriad of applications. The process allows for complex designs and precise dimensions, making it an ideal choice for manufacturers looking to innovate.

The Aluminum Extrusion Process

The aluminum extrusion process consists of several key steps:

1. Billet Preparation: A solid aluminum billet is heated to a specific temperature, making it pliable.

2. Extrusion: The heated billet is forced through a die using a hydraulic press, creating the desired shape.

3. Cooling: The extruded material is cooled, typically using air or water, to solidify its shape.

4. Cutting: Once cooled, the extruded aluminum is cut into specified lengths.

5. Finishing: The final product may undergo additional processes such as anodizing or painting to enhance appearance and durability.

This efficient process not only reduces waste but also allows for high-volume production of complex shapes.

Benefits of Aluminum Extrusion

1. Cost-Effectiveness

One of the primary advantages of aluminum extrusion is its cost-effectiveness. The process minimizes waste and reduces the need for secondary machining operations, which can significantly lower production costs. In Arizona, where manufacturing efficiency is crucial, this benefit is particularly appealing. Moreover, the ability to produce large quantities at once means that manufacturers can enjoy economies of scale.

2. Lightweight Yet Strong

Aluminum is known for its high strength-to-weight ratio. This quality makes it an excellent choice for industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. In Arizona's growing aerospace sector, lightweight materials are essential for innovation. For example, aircraft components made from aluminum extrusions can significantly reduce overall aircraft weight without compromising structural integrity.

3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer that prevents corrosion. This characteristic is especially beneficial in Arizona's arid climate, where materials are often exposed to harsh environmental conditions. Structures made from aluminum extrusions require less maintenance and have a longer lifespan compared to those made from other materials like steel or iron.

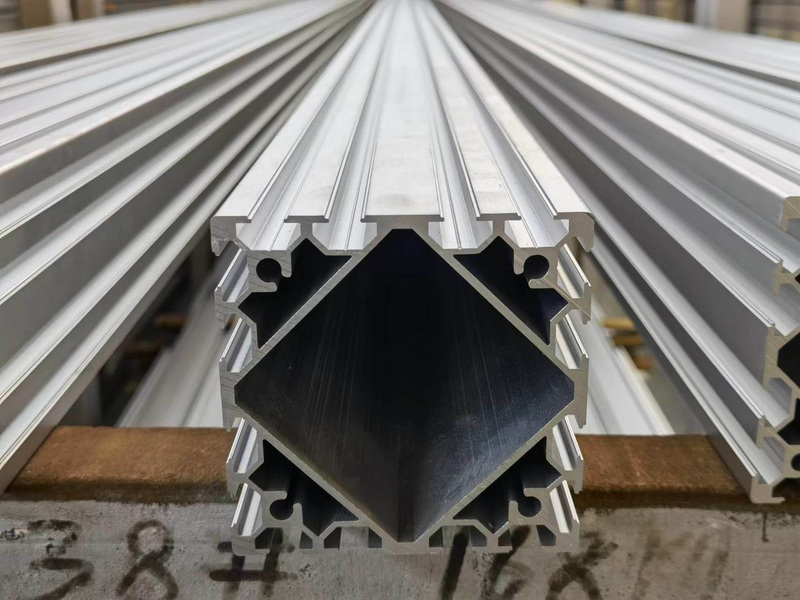

4. Design Flexibility

The extrusion process allows for the creation of intricate shapes that would be difficult or impossible to achieve with other manufacturing methods. This design flexibility enables engineers and designers in Arizona to push the boundaries of innovation in product development. Whether it's custom profiles for architectural applications or specialized components for machinery, aluminum extrusion offers unparalleled versatility.

5. Sustainability

Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice for manufacturers. In Arizona, where sustainability initiatives are increasingly prioritized, using recycled aluminum can enhance a company's green credentials. The recycling process requires only about 5% of the energy needed to produce new aluminum from ore, significantly reducing carbon footprints.

Applications of Aluminum Extrusion in Arizona

Aluminum extrusions find applications across various sectors in Arizona:

- Construction: Used in window frames, doors, and structural components due to their durability and aesthetic appeal.

- Transportation: Lightweight components for vehicles and public transport systems contribute to improved fuel efficiency.

- Electronics: Heat sinks and enclosures benefit from aluminum's thermal conductivity while providing lightweight protection.

- Consumer Goods: Products ranging from furniture to appliances utilize aluminum extrusions for their modern look and functionality.

- Renewable Energy: Aluminum extrusions are used in solar panel frames and mounting systems due to their lightweight nature and resistance to corrosion.

Case Study: Solar Energy Applications

In recent years, Arizona has become a leader in solar energy production. Aluminum extrusions play a critical role in this industry by providing lightweight yet sturdy frames for solar panels. These frames not only support the panels but also withstand harsh weather conditions typical of the region. As more companies invest in renewable energy solutions, the demand for aluminum extrusions in this sector continues to grow.

Local Manufacturers Leading the Charge

Arizona is home to several leading manufacturers specializing in aluminum extrusion. Companies like APEL Extrusions have established state-of-the-art facilities that produce high-quality extruded products tailored to various industries. Their commitment to innovation and efficiency sets them apart in the competitive landscape.

APEL Extrusions Facility

APEL Extrusions operates advanced manufacturing lines equipped with cutting-edge technology that ensures precision and quality control throughout the production process. Their team works closely with clients to develop custom solutions that meet specific needs while adhering to stringent industry standards.

Additionally, local manufacturers are increasingly adopting sustainable practices by utilizing recycled materials in their production processes, further enhancing their appeal in environmentally conscious markets.

The Future of Aluminum Extrusion in Arizona

As industries evolve and new technologies emerge, the demand for aluminum extrusions is expected to grow. Local manufacturers are investing in advanced equipment and processes to meet this demand while maintaining high standards of quality and sustainability.

Emerging Trends

Several trends are shaping the future of aluminum extrusion in Arizona:

- Increased Automation: Manufacturers are integrating automation into their processes to enhance efficiency and reduce labor costs.

- Advanced Alloys: Research into new aluminum alloys with improved properties will expand application possibilities across various sectors.

- Customization: As industries seek tailored solutions, manufacturers will focus on providing highly customized products that meet specific client needs.

- Sustainable Practices: Continued emphasis on sustainability will drive innovations in recycling processes and eco-friendly manufacturing techniques.

Conclusion

In summary, aluminum extrusion offers numerous benefits that make it an attractive option for manufacturers in Arizona. From cost-effectiveness and lightweight strength to corrosion resistance and design flexibility, the advantages are clear. As local companies continue to innovate and expand their capabilities while prioritizing sustainability, the future looks bright for aluminum extrusion in the Grand Canyon State.

FAQ

1. What industries benefit most from aluminum extrusion?

Aluminum extrusion benefits various industries including construction, transportation, electronics, consumer goods, and renewable energy due to its versatility and strength.

2. How does aluminum extrusion compare to other manufacturing processes?

Aluminum extrusion is generally more cost-effective than other methods because it minimizes waste and reduces the need for secondary machining operations.

3. Is aluminum extrusion environmentally friendly?

Yes, aluminum is 100% recyclable without losing its properties, making it an environmentally sustainable choice for manufacturing.

4. What are some common applications of aluminum extrusions?

Common applications include window frames, vehicle components, heat sinks in electronics, solar panel frames, and various consumer products.

5. How do local manufacturers ensure quality in aluminum extrusion?

Local manufacturers invest in advanced technology and adhere to strict quality control measures throughout the production process to ensure high-quality products.