Content Menu

● Understanding 3x3 Aluminum Extrusions

>> Benefits of Using 3x3 Aluminum Extrusions

● Applications of 3x3 Aluminum Extrusions

>> 1. Construction and Architecture

>> 2. Manufacturing and Industrial Applications

>> 3. Automotive Industry

>> 4. Transportation Sector

>> 5. Furniture Manufacturing

>> 6. Renewable Energy Solutions

>> 7. DIY Projects and Home Improvement

● Innovations in Aluminum Extrusion Technology

● Conclusion

● Related Questions

>> 1. What Are the Advantages of Using Aluminum Extrusion?

>> 2. How Are Aluminum Extrusions Manufactured?

>> 3. Can You Weld Aluminum Extrusions?

>> 4. What Tools Are Needed for Working with Aluminum Extrusions?

>> 5. How Do You Maintain Aluminum Extrusion Products?

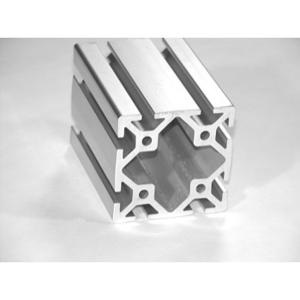

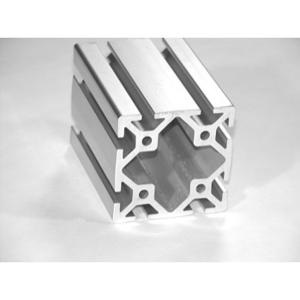

Aluminum extrusions have become a staple in various industries due to their lightweight, strength, and versatility. Among the different sizes and profiles available, the 3x3 aluminum extrusion stands out for its unique applications and benefits. This article will explore the numerous applications of 3x3 aluminum extrusions, highlighting their significance in construction, manufacturing, automotive, and more.

Understanding 3x3 Aluminum Extrusions

Before diving into specific applications, it's essential to understand what 3x3 aluminum extrusions are. These extrusions are made from aluminum alloy and feature a square profile with dimensions of 3 inches by 3 inches. The extrusion process involves forcing heated aluminum through a die to create a specific shape, allowing for efficient production of long sections with consistent cross-sections.

Benefits of Using 3x3 Aluminum Extrusions

- Lightweight: Aluminum is significantly lighter than steel or other metals, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents rust and corrosion.

- Versatility: The square profile allows for various configurations and applications across industries.

- Ease of Fabrication: 3x3 aluminum extrusions can be easily cut, drilled, and welded, enabling custom solutions.

- Aesthetic Appeal: The clean lines and modern look of aluminum extrusions make them an attractive choice for architectural designs.

- Recyclability: Aluminum is highly recyclable without losing its properties, making it an environmentally friendly choice.

Applications of 3x3 Aluminum Extrusions

1. Construction and Architecture

One of the most significant applications of 3x3 aluminum extrusions is in construction and architecture. They are used in:

- Structural Frameworks: The strength-to-weight ratio of aluminum makes it ideal for building frames, supports, and scaffolding systems. For instance, many modern buildings utilize aluminum frameworks to reduce overall weight while maintaining structural integrity.

- Window Frames: 3x3 aluminum extrusions provide durable frames for windows that require minimal maintenance. Their resistance to corrosion ensures that they remain functional and visually appealing over time.

- Facades and Cladding: They can be used in the exterior cladding of buildings, offering both aesthetic appeal and structural support. The versatility in design allows architects to create innovative facades that enhance the building's appearance while providing insulation.

2. Manufacturing and Industrial Applications

In manufacturing, 3x3 aluminum extrusions are utilized for:

- Assembly Line Structures: They can create modular assembly line setups that are flexible and easy to modify as production needs change. This adaptability is crucial in industries where production processes frequently evolve.

- Workstations: Custom workstations can be built using these extrusions, providing ergonomic solutions for workers. The ability to adjust height and configuration makes them suitable for various tasks.

- Machine Guards: The robustness of 3x3 aluminum extrusions makes them suitable for creating protective barriers around machinery. This enhances workplace safety by preventing accidents while allowing visibility.

3. Automotive Industry

The automotive industry benefits from the use of 3x3 aluminum extrusions in several ways:

- Chassis Components: Lightweight yet strong, these extrusions are used in vehicle chassis to improve fuel efficiency without sacrificing safety. Many electric vehicles leverage aluminum components to offset battery weight.

- Interior Frameworks: They can be used in the construction of vehicle interiors, such as frames for seats or dashboards. This not only reduces weight but also allows for innovative design solutions.

4. Transportation Sector

In transportation, particularly in railways and public transport systems:

- Rail Car Construction: 3x3 aluminum extrusions are used to build lightweight rail cars that enhance energy efficiency. Their strength allows for larger passenger capacities without increasing energy consumption.

- Bus Frames: They provide structural integrity while keeping the overall weight low for buses and other public transport vehicles. This results in lower fuel costs and reduced emissions.

5. Furniture Manufacturing

The furniture industry has also embraced the use of 3x3 aluminum extrusions:

- Modular Furniture Systems: These extrusions allow for the design of versatile modular furniture that can be easily reconfigured. This flexibility caters to changing consumer needs in both residential and commercial spaces.

- Outdoor Furniture: Their corrosion resistance makes them perfect for outdoor settings where exposure to elements is a concern. Aluminum outdoor furniture is not only durable but also lightweight for easy rearrangement.

6. Renewable Energy Solutions

With the rise in renewable energy initiatives:

- Solar Panel Mounting Systems: 3x3 aluminum extrusions are commonly used to create frames for solar panels due to their durability and lightweight nature. These mounting systems ensure stability while allowing easy installation and maintenance.

- Wind Turbine Towers: They can also be utilized in constructing components for wind turbines, contributing to sustainable energy solutions by enhancing the efficiency of wind energy capture.

7. DIY Projects and Home Improvement

For enthusiasts engaged in DIY projects:

- Custom Shelving Units: Homeowners can use 3x3 aluminum extrusions to build custom shelving units that fit their specific needs. The ability to design according to personal taste adds a unique touch to home decor.

- Garden Structures: From trellises to raised garden beds, these extrusions offer a modern touch to outdoor spaces while ensuring durability against weather conditions.

Innovations in Aluminum Extrusion Technology

The advancements in extrusion technology have led to even more possibilities with 3x3 aluminum extrusions:

- Advanced Alloys: Newer aluminum alloys provide enhanced strength and corrosion resistance, making them suitable for even more demanding applications across various industries.

- Surface Treatments: Techniques such as anodizing or powder coating improve aesthetics while adding an extra layer of protection against environmental factors.

- Customization Options: Manufacturers now offer customizable lengths, finishes, and even pre-drilled holes or slots which simplify assembly processes for end-users.

Conclusion

The versatility of 3x3 aluminum extrusions makes them an invaluable asset across various industries. Their lightweight nature combined with strength and resistance to corrosion allows them to be utilized in construction, manufacturing, automotive applications, transportation, furniture design, renewable energy solutions, and even DIY projects at home. As technology advances and industries evolve, the demand for such adaptable materials will likely continue to grow.

Related Questions

1. What Are the Advantages of Using Aluminum Extrusion?

Aluminum extrusion offers numerous advantages including lightweight properties, corrosion resistance, versatility in design, ease of fabrication, and cost-effectiveness over time due to its durability.

2. How Are Aluminum Extrusions Manufactured?

Aluminum extrusions are manufactured by heating aluminum billets until they become malleable and then forcing them through a die that shapes them into desired profiles like the 3x3 square shape.

3. Can You Weld Aluminum Extrusions?

Yes, you can weld aluminum extrusions; however, it requires specific techniques such as TIG or MIG welding due to the unique properties of aluminum compared to other metals.

4. What Tools Are Needed for Working with Aluminum Extrusions?

Common tools include saws (for cutting), drills (for making holes), welding equipment (for joining), and measuring tools (for ensuring precision).

5. How Do You Maintain Aluminum Extrusion Products?

Maintenance typically involves regular cleaning with mild detergents to remove dirt or debris and inspecting for any signs of wear or corrosion over time.