Content Menu

● Understanding Aluminum Extrusion

● Types of Aluminum Extrusion Fasteners

● How Aluminum Extrusion Fasteners Work

● Advantages of Using Aluminum Extrusion Fasteners

● Applications of Aluminum Extrusion Fasteners

● Innovations in Aluminum Extrusion Fastening Technology

● Conclusion

● FAQ

>> 1. What materials are commonly used for aluminum extrusion fasteners?

>> 2. Can aluminum extrusion fasteners be reused?

>> 3. How do T-Nuts work with aluminum extrusions?

>> 4. Are aluminum extrusion fasteners resistant to corrosion?

>> 5. What tools are needed to assemble structures with aluminum extrusion fasteners?

● Citations:

Aluminum extrusion fasteners are essential components in the assembly and construction of structures using aluminum extrusions. These fasteners enable the joining of various aluminum profiles, providing stability and strength to the final assembly. This article will delve into the types of aluminum extrusion fasteners, their applications, how they work, and their advantages in various industries.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create specific shapes or profiles. This process allows for the creation of complex designs that are lightweight yet strong. The extruded aluminum can be used in various applications, from structural frames to decorative elements.

The extrusion process involves several key steps:

- Preparation of the Die: The die is heated to ensure even metal flow.

- Preheating the Aluminum Billet: The billet is heated to make it malleable.

- Extrusion: A powerful ram pushes the heated billet through the die, shaping it.

- Cooling: The extruded shape is cooled to solidify it.

- Cutting: The extruded aluminum is cut to specified lengths.

This method not only allows for efficient production but also enables manufacturers to create custom profiles tailored to specific applications.

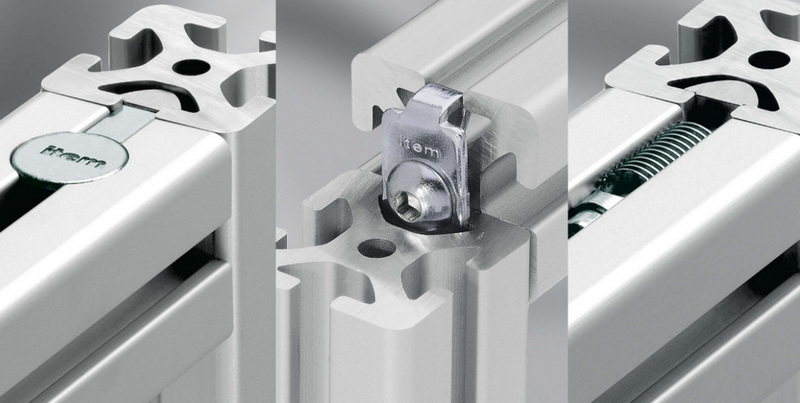

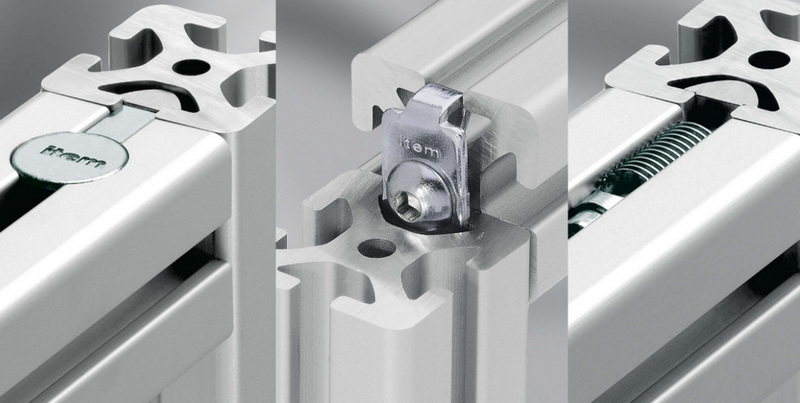

Types of Aluminum Extrusion Fasteners

Aluminum extrusion fasteners come in various forms, each designed for specific applications. Some common types include:

- T-Nuts: These nuts are designed to fit into T-slots of aluminum profiles, allowing for easy attachment of components. They can be easily adjusted along the slot for optimal positioning.

- Bolts and Screws: Various bolts and screws are used to secure connections between extrusions. They can be made from steel or stainless steel for enhanced strength and durability.

- Universal Fasteners: These fasteners connect multiple profiles and are versatile for different configurations. They often feature multiple attachment points.

- Angle Connectors: Used for creating right angles in assemblies, these connectors provide strong joints that enhance structural integrity.

- Clamp Fasteners: These allow for quick assembly without drilling, making them ideal for temporary structures or setups that require frequent adjustments.

How Aluminum Extrusion Fasteners Work

The functionality of aluminum extrusion fasteners is largely based on their design and the principles of mechanical fastening. Here's how they work:

1. Insertion into T-Slots: T-Nuts and other similar fasteners are inserted into the T-slots of the aluminum profile. This design allows for easy adjustment and repositioning, facilitating quick assembly and disassembly.

2. Tightening Mechanism: Once positioned, bolts or screws are tightened using simple hand tools. The tightening creates friction that holds the components securely together, ensuring stability under load.

3. Load Distribution: The design of these fasteners ensures that loads are evenly distributed across the connection points, reducing stress on individual components. This is particularly important in high-stress applications where structural integrity is critical.

4. Modularity: Many aluminum extrusion fasteners allow for modular assembly, meaning structures can be easily modified or expanded as needed without requiring extensive rework or new components.

5. Flexibility in Design: The ability to adjust and reposition fasteners enables designers to create dynamic structures that can evolve over time, accommodating new requirements or changes in use.

Advantages of Using Aluminum Extrusion Fasteners

The use of aluminum extrusion fasteners offers numerous benefits:

- Lightweight: Aluminum fasteners contribute to maintaining a lightweight structure without sacrificing strength. This characteristic is especially valuable in industries like aerospace and automotive.

- Corrosion Resistance: Aluminum naturally resists corrosion, making these fasteners ideal for outdoor applications where exposure to moisture and other elements can lead to degradation.

- Versatility: They can be used in a wide range of applications, from industrial machinery to DIY projects. Their adaptability makes them suitable for both permanent installations and temporary setups.

- Ease of Assembly: Most aluminum extrusion fasteners require minimal tools for assembly, making them user-friendly and accessible even for those with limited experience in construction or fabrication.

- Reusability: Many fasteners can be reused in different configurations or projects, promoting sustainability by reducing waste and material costs.

Applications of Aluminum Extrusion Fasteners

Aluminum extrusion fasteners are utilized across various industries due to their versatility:

- Construction: Used in building frames, scaffolding, and architectural elements such as window frames and facades. Their lightweight nature contributes to energy efficiency in buildings by reducing overall structural weight.

- Manufacturing: Essential in creating machinery frames and equipment supports where strength-to-weight ratios are crucial. They enable manufacturers to build robust systems that can withstand operational stresses while remaining lightweight.

- Automotive: Employed in lightweight vehicle structures and components such as chassis and body panels. The automotive industry increasingly relies on aluminum extrusions to improve fuel efficiency without compromising safety.

- Furniture Design: Used in modular furniture systems that require adjustable configurations, allowing users to customize their spaces easily. This flexibility appeals to both residential and commercial markets where adaptability is key.

- Electronics Enclosures: Fasteners are used in creating enclosures for electronic devices, providing protection while allowing for efficient heat dissipation due to aluminum's thermal conductivity properties.

Innovations in Aluminum Extrusion Fastening Technology

Recent advancements have led to innovative fastening solutions that enhance the performance and usability of aluminum extrusions:

- Self-Locking Mechanisms: Some modern fasteners incorporate self-locking features that prevent loosening over time due to vibrations or thermal expansion, increasing reliability in demanding environments.

- Integrated Systems: New designs combine multiple fastening functions into single units, reducing assembly time and complexity while improving overall structural integrity.

- Smart Fastening Solutions: The integration of sensors into fastening systems allows for real-time monitoring of stress and load conditions, providing valuable data that can inform maintenance schedules or design adjustments.

Conclusion

Aluminum extrusion fasteners play a crucial role in modern construction and manufacturing processes. Their ability to provide strong, lightweight connections makes them an essential component in various applications across multiple industries. With advancements in design and materials, these fasteners continue to evolve, offering even greater benefits in terms of efficiency, sustainability, and adaptability.

As industries move towards more modular designs that require flexibility and ease of assembly, aluminum extrusion fasteners will remain at the forefront of innovative solutions that meet these demands. Their unique properties make them indispensable for engineers, architects, manufacturers, and DIY enthusiasts alike.

FAQ

1. What materials are commonly used for aluminum extrusion fasteners?

Most aluminum extrusion fasteners are made from steel or stainless steel due to their higher strength compared to aluminum while maintaining compatibility with aluminum profiles.

2. Can aluminum extrusion fasteners be reused?

Yes, many types of aluminum extrusion fasteners can be reused in different configurations or projects without losing their effectiveness or structural integrity over time.

3. How do T-Nuts work with aluminum extrusions?

T-Nuts fit into the T-slots of aluminum profiles and allow for easy attachment of other components by tightening bolts or screws into them; this design promotes flexibility in assembly configurations.

4. Are aluminum extrusion fasteners resistant to corrosion?

Yes, aluminum itself has natural corrosion resistance properties due to its oxide layer formation when exposed to air; this makes these fasteners suitable for outdoor use without significant degradation over time.

5. What tools are needed to assemble structures with aluminum extrusion fasteners?

Typically, only basic hand tools such as Allen wrenches and screwdrivers are required for assembly; this simplicity enhances user accessibility during construction projects.

Citations:

[1] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[2] https://www.lametals.co.uk/blog/what-is-aluminium-extrusion/

[3] https://blog.item24.com/en/the-item-building-kit-system/overview-of-aluminium-profile-fasteners-a-solution-for-every-application/

[4] https://www.framingtech.com/products/fasteners

[5] https://www.youtube.com/watch?v=k9j9TRgx1uw

[6] https://www.youtube.com/watch?v=iBoecaVaWkA

[7] https://www.ccmfg.net/what-is-aluminum-extrusion/

[8] https://www.framingtech.com/products/connectors/universal-fasteners

[9] https://www.tslots.com/products/fasteners/

[10] https://www.youtube.com/watch?v=gJIChIs4g6A