Content Menu

● Introduction

● Understanding U Shaped Aluminum Channels

● Key Benefits of U Shaped Aluminum Channels

>> Strength and Durability

>> Lightweight Nature

>> Versatility in Applications

>> Cost-Effectiveness

● Applications of U Shaped Aluminum Channels

>> Residential Construction

>> Commercial Projects

>> Industrial Uses

● Customization and Manufacturing

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using U shaped aluminum channels in construction?

>> 2. How do U shaped aluminum channels compare to other aluminum profiles?

>> 3. Can U shaped aluminum channels be customized for specific applications?

>> 4. What are some common applications of U shaped aluminum channels in commercial projects?

>> 5. How does the lightweight nature of U shaped aluminum channels benefit construction projects?

Introduction

U shaped aluminum channels, also known as U channel aluminum extrusions, are versatile components widely used in various industries due to their unique properties and benefits. These channels are characterized by their U-shaped cross-section, which provides excellent structural integrity and flexibility in design. This article explores the numerous applications that can benefit from U shaped aluminum channels, highlighting their advantages in construction, manufacturing, and other sectors.

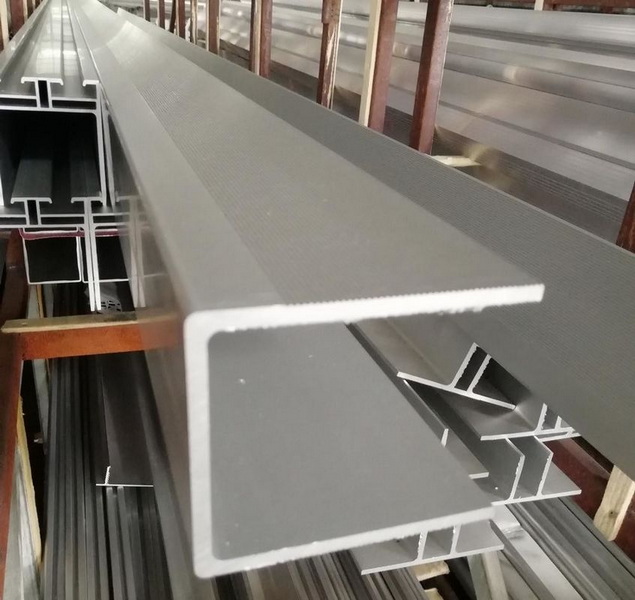

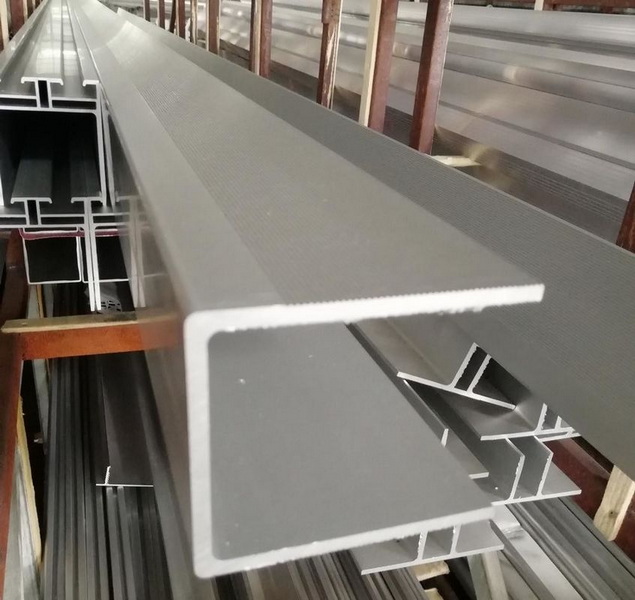

Understanding U Shaped Aluminum Channels

U shaped aluminum channels are produced through the aluminum extrusion process, where aluminum billets are heated and forced through a die to create specific shapes. The U channel design offers a combination of strength and lightweight characteristics, making it an ideal choice for many applications. Compared to other aluminum profiles, such as C-channels and T-channels, U shaped channels provide a greater surface area for attachment and support, enhancing their usability in various projects.

Key Benefits of U Shaped Aluminum Channels

Strength and Durability

One of the primary advantages of U shaped aluminum channels is their strength. Aluminum is known for its high strength-to-weight ratio, which means that U channel aluminum extrusions can support significant loads without adding excessive weight to a structure. This property is particularly beneficial in construction, where structural integrity is paramount. Additionally, aluminum is naturally resistant to corrosion, making U shaped channels suitable for both indoor and outdoor applications.

Lightweight Nature

The lightweight nature of U shaped aluminum channels makes them easy to handle and install. This characteristic is especially important in construction and manufacturing, where reducing labor costs and improving efficiency are critical. Workers can easily transport and manipulate these channels, leading to faster project completion times. The reduced weight also minimizes the need for heavy-duty support structures, further enhancing the overall efficiency of a project.

Versatility in Applications

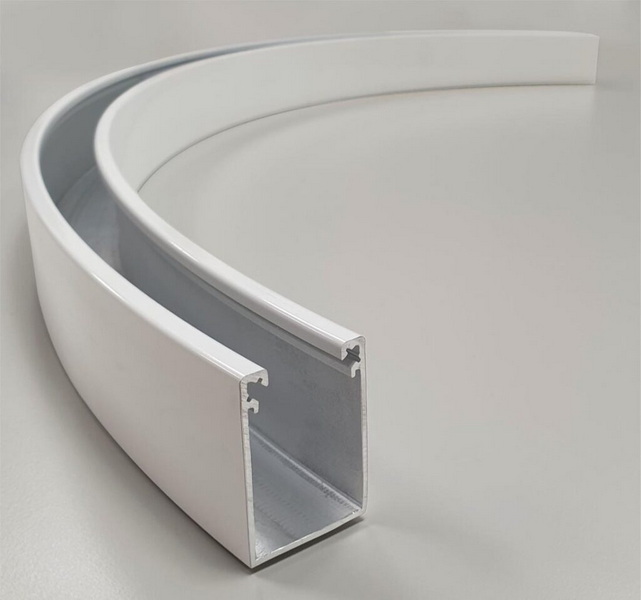

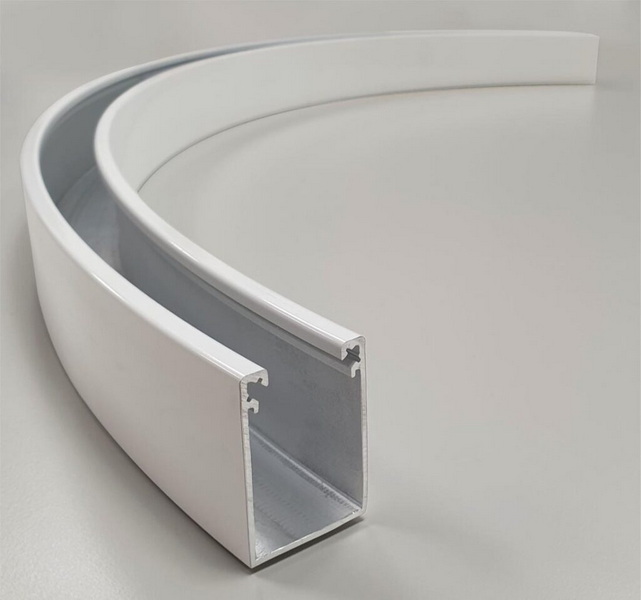

U shaped aluminum channels are incredibly versatile and can be used in a wide range of applications. Their design allows for easy integration into various systems, making them suitable for both structural and decorative purposes. From framing and supports to custom fixtures and displays, U shaped channels can adapt to meet the specific needs of different projects.

Cost-Effectiveness

Using U shaped aluminum channels can lead to significant cost savings in the long run. Their durability and resistance to corrosion reduce maintenance and replacement costs, while their lightweight nature can lower transportation and installation expenses. Additionally, the ability to customize U channel aluminum extrusions means that businesses can create tailored solutions that fit their exact requirements, further enhancing cost efficiency.

Applications of U Shaped Aluminum Channels

Residential Construction

In residential construction, U shaped aluminum channels are commonly used in window frames, door frames, and railings. Their strength and durability make them an excellent choice for supporting structures that require stability and safety. For instance, U shaped channels can be used to create sturdy window frames that withstand the elements while providing an aesthetically pleasing finish.

Commercial Projects

U shaped aluminum channels are also widely used in commercial projects. They can be found in signage, display fixtures, and structural supports. For example, retail stores often utilize U shaped channels to create eye-catching displays that showcase products effectively. The channels can be easily integrated into various designs, allowing for creative and functional solutions that enhance the shopping experience.

Industrial Uses

In industrial settings, U shaped aluminum channels play a crucial role in machinery, equipment, and custom fabrication. Their strength and lightweight properties make them ideal for constructing frames and supports for heavy machinery. Additionally, U shaped channels can be used to create custom solutions for specific industrial applications, such as conveyor systems and assembly lines.

Customization and Manufacturing

One of the significant advantages of U shaped aluminum channels is the ability to customize them according to specific project requirements. Many manufacturers offer custom aluminum extrusion services, allowing businesses to create unique profiles that meet their needs. This customization can include variations in size, thickness, and surface finish, ensuring that the final product aligns perfectly with the intended application.

When selecting a supplier for U channel aluminum extrusions, it is essential to consider factors such as quality assurance, production capabilities, and delivery times. A reliable supplier can provide high-quality products that meet industry standards, ensuring that projects are completed successfully and on time.

Conclusion

U shaped aluminum channels are invaluable components in various applications, offering strength, durability, and versatility. Their lightweight nature and cost-effectiveness make them an ideal choice for construction, commercial projects, and industrial uses. As businesses continue to seek innovative solutions, U shaped aluminum channels will undoubtedly play a significant role in shaping the future of design and manufacturing.

Frequently Asked Questions

1. What are the primary benefits of using U shaped aluminum channels in construction?

U shaped aluminum channels offer strength, durability, lightweight properties, versatility, and cost-effectiveness, making them ideal for various construction applications.

2. How do U shaped aluminum channels compare to other aluminum profiles?

U shaped aluminum channels provide a greater surface area for attachment and support compared to other profiles like C-channels and T-channels, enhancing their usability in different projects.

3. Can U shaped aluminum channels be customized for specific applications?

Yes, many manufacturers offer custom aluminum extrusion services, allowing businesses to create U shaped channels tailored to their specific project requirements.

4. What are some common applications of U shaped aluminum channels in commercial projects?

U shaped aluminum channels are commonly used in signage, display fixtures, and structural supports in retail and commercial environments.

5. How does the lightweight nature of U shaped aluminum channels benefit construction projects?

The lightweight nature of U shaped aluminum channels makes them easy to handle and install, reducing labor costs and improving overall project efficiency.