Content Menu

● Understanding T-Shaped Aluminum Extrusions

● Key Advantages of T-Shaped Aluminum Extrusions

● Applications of T-Shaped Aluminum Extrusions

>> Construction and Architecture

>> Automotive Industry

>> Aerospace Applications

>> Furniture Design

>> Industrial Equipment

>> Electronics and Telecommunications

>> Signage and Displays

>> Robotics and Automation

>> Marine Applications

>> Home Improvement Projects

● Conclusion

● Frequently Asked Questions

>> 1. What are T-shaped aluminum extrusions used for?

>> 2. What are the advantages of using aluminum extrusions?

>> 3. Can T-shaped aluminum extrusions be customized?

>> 4. How do T-shaped aluminum extrusions compare to other materials?

>> 5. Are T-shaped aluminum extrusions environmentally friendly?

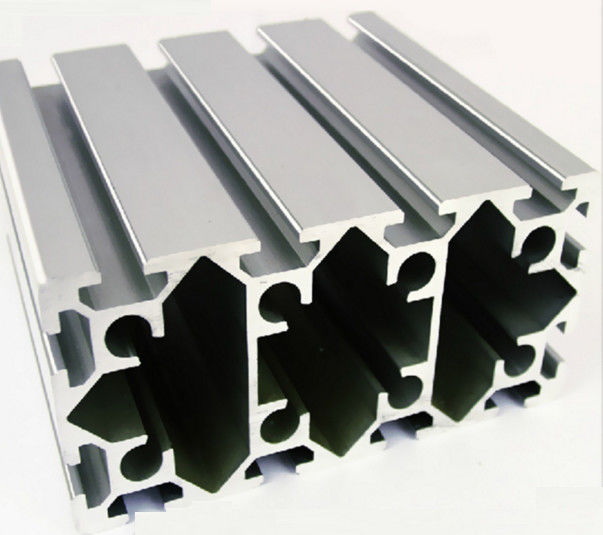

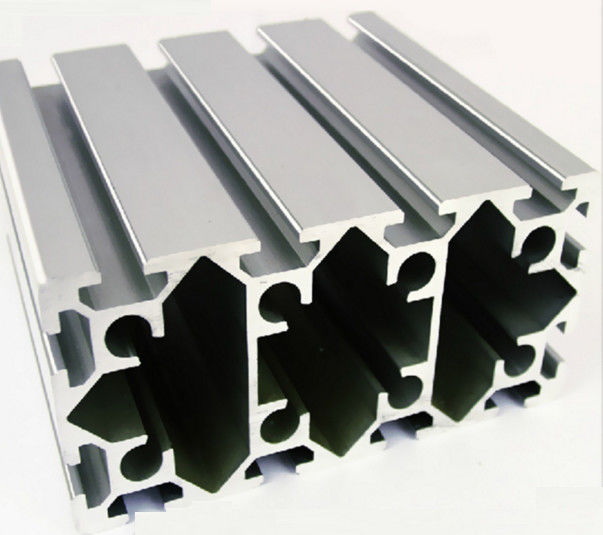

Understanding T-Shaped Aluminum Extrusions

T-shaped aluminum extrusions are versatile structural components widely used across various industries due to their unique shape and properties. This article explores the numerous applications that benefit from T-shaped aluminum extrusions, highlighting their advantages, design flexibility, and the industries that utilize them.

T-shaped aluminum extrusions are formed by pushing aluminum through a die to create a specific cross-sectional shape resembling the letter "T." This design features a vertical stem and a horizontal top, providing excellent structural integrity and load-bearing capabilities. The lightweight nature of aluminum, combined with its strength and resistance to corrosion, makes T-shaped extrusions an ideal choice for many applications.

Key Advantages of T-Shaped Aluminum Extrusions

1. Strength-to-Weight Ratio: Aluminum has a high strength-to-weight ratio, making T-shaped extrusions strong yet lightweight. This property is crucial in applications where reducing weight is essential, such as in aerospace and automotive industries.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This characteristic is particularly beneficial in outdoor applications or environments exposed to moisture.

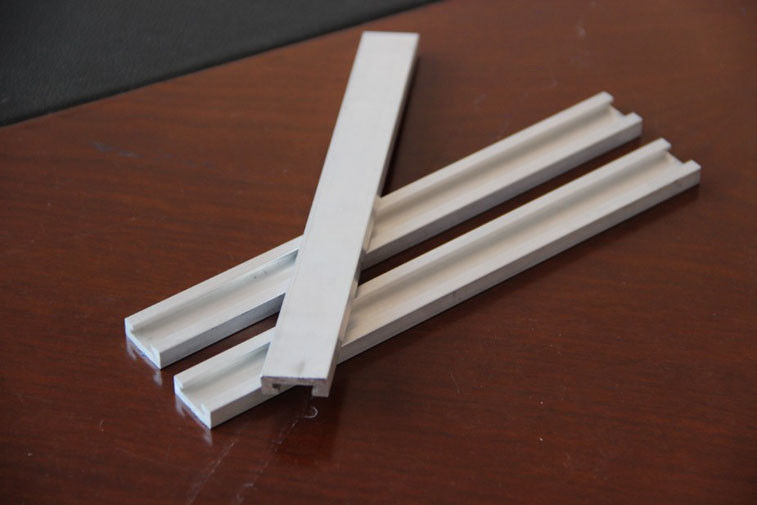

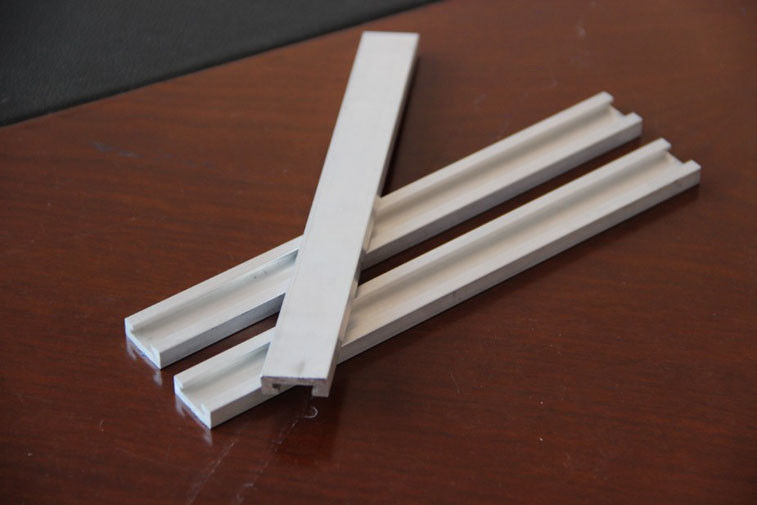

3. Design Flexibility: T-shaped extrusions can be easily customized to meet specific design requirements. They can be cut, drilled, and machined to fit various applications, allowing for creative and innovative designs.

4. Ease of Assembly: T-shaped aluminum extrusions can be easily assembled using standard fasteners and connectors. This ease of assembly reduces labor costs and time during construction or manufacturing processes.

5. Recyclability: Aluminum is 100% recyclable without losing its properties. This sustainability aspect makes T-shaped aluminum extrusions an environmentally friendly choice for many applications.

Applications of T-Shaped Aluminum Extrusions

Construction and Architecture

T-shaped aluminum extrusions are widely used in the construction industry for framing, supports, and structural components. Their strength and lightweight nature make them ideal for building facades, window frames, and curtain walls. Architects and builders appreciate the aesthetic appeal of aluminum, as it can be finished in various colors and textures. The ability to create intricate designs while maintaining structural integrity makes T-shaped extrusions a preferred choice in modern architecture.

In addition to their aesthetic benefits, T-shaped aluminum extrusions contribute to energy efficiency in buildings. They can be integrated into thermal break systems, which help reduce heat transfer, thereby improving insulation and reducing energy costs. This feature is particularly important in regions with extreme temperatures, where maintaining a comfortable indoor environment is essential.

Automotive Industry

In the automotive sector, T-shaped aluminum extrusions are used for various components, including chassis, body panels, and structural reinforcements. The lightweight nature of aluminum helps improve fuel efficiency while maintaining safety standards. Additionally, aluminum's resistance to corrosion enhances the longevity of automotive parts.

The automotive industry is increasingly focusing on sustainability, and aluminum plays a crucial role in this shift. T-shaped aluminum extrusions can be recycled at the end of a vehicle's life cycle, reducing waste and promoting a circular economy. Manufacturers are also exploring innovative designs that utilize aluminum extrusions to create lighter and more efficient vehicles, contributing to lower emissions and better performance.

Aerospace Applications

The aerospace industry benefits significantly from T-shaped aluminum extrusions due to their high strength-to-weight ratio. These extrusions are used in aircraft frames, wing structures, and other critical components. The lightweight properties of aluminum contribute to fuel efficiency and overall performance in aviation.

Moreover, T-shaped aluminum extrusions are essential in the manufacturing of satellite structures and components. Their ability to withstand extreme temperatures and pressures makes them suitable for aerospace applications where reliability is paramount. As the aerospace industry continues to evolve, the demand for lightweight materials like aluminum will only increase, driving innovation in T-shaped extrusion designs.

Furniture Design

T-shaped aluminum extrusions are increasingly popular in modern furniture design. They are used in the construction of tables, chairs, and shelving units, providing a sleek and contemporary look. The ability to customize the length and finish of the extrusions allows designers to create unique and functional pieces.

In addition to aesthetics, T-shaped aluminum extrusions offer durability and stability in furniture applications. They can support heavy loads while maintaining their shape, making them ideal for both residential and commercial furniture. Designers appreciate the versatility of aluminum, as it can be combined with other materials, such as glass or wood, to create striking contrasts and innovative designs.

Industrial Equipment

In industrial settings, T-shaped aluminum extrusions are used for machine frames, conveyor systems, and workstations. Their strength and durability make them suitable for heavy-duty applications, while their lightweight nature allows for easy mobility and reconfiguration of equipment.

The modularity of T-shaped aluminum extrusions is a significant advantage in industrial applications. They can be easily assembled and disassembled, allowing for quick changes in layout or design. This flexibility is particularly beneficial in manufacturing environments where efficiency and adaptability are crucial.

Electronics and Telecommunications

T-shaped aluminum extrusions are utilized in the electronics industry for housing and supporting electronic components. Their thermal conductivity helps dissipate heat, ensuring the longevity and reliability of electronic devices. Additionally, they are used in telecommunications for mounting antennas and other equipment.

As technology advances, the demand for efficient heat management in electronic devices increases. T-shaped aluminum extrusions provide an effective solution for thermal management, helping to prevent overheating and prolonging the lifespan of electronic components. Their lightweight nature also makes them ideal for portable devices, where weight reduction is essential.

Signage and Displays

T-shaped aluminum extrusions are commonly used in signage and display systems. Their structural integrity allows for the creation of sturdy and visually appealing signs, while the lightweight nature makes installation easy. They can be finished in various colors to match branding requirements.

In retail environments, T-shaped aluminum extrusions are often used to create eye-catching displays that attract customers. Their versatility allows for the design of custom signage that can be easily updated or modified, making them a popular choice for businesses looking to enhance their marketing efforts.

Robotics and Automation

In robotics and automation, T-shaped aluminum extrusions are used to build frames and structures for robotic arms and automated systems. Their strength and flexibility allow for the creation of complex designs that can withstand the rigors of industrial applications.

The use of T-shaped aluminum extrusions in robotics is growing as industries seek to automate processes for increased efficiency. These extrusions provide a lightweight yet robust framework for robotic systems, enabling precise movements and reliable performance. As automation technology continues to advance, the role of T-shaped aluminum extrusions will become even more significant.

Marine Applications

T-shaped aluminum extrusions are also used in marine applications, such as boat frames and supports. Their corrosion resistance makes them ideal for use in saltwater environments, ensuring the longevity and durability of marine vessels.

In the boating industry, T-shaped aluminum extrusions are favored for their lightweight properties, which contribute to improved fuel efficiency and performance on the water. Additionally, their ability to withstand harsh marine conditions makes them a reliable choice for boat manufacturers and owners alike.

Home Improvement Projects

DIY enthusiasts often use T-shaped aluminum extrusions in home improvement projects. They can be used for creating custom shelving, frames, and supports, allowing homeowners to personalize their spaces with unique designs.

The versatility of T-shaped aluminum extrusions makes them suitable for a wide range of home improvement applications. Whether building a custom closet system or designing a unique piece of furniture, these extrusions provide the strength and flexibility needed to bring creative ideas to life.

Conclusion

T-shaped aluminum extrusions are a vital component in various industries, offering numerous benefits such as strength, lightweight properties, and design flexibility. Their applications range from construction and automotive to electronics and home improvement, showcasing their versatility and adaptability. As industries continue to innovate, the demand for T-shaped aluminum extrusions is expected to grow, making them an essential material for future projects.

Frequently Asked Questions

1. What are T-shaped aluminum extrusions used for?

T-shaped aluminum extrusions are used in construction, automotive, aerospace, furniture design, industrial equipment, electronics, signage, robotics, marine applications, and home improvement projects.

2. What are the advantages of using aluminum extrusions?

Aluminum extrusions offer a high strength-to-weight ratio, corrosion resistance, design flexibility, ease of assembly, and recyclability.

3. Can T-shaped aluminum extrusions be customized?

Yes, T-shaped aluminum extrusions can be easily customized in terms of length, finish, and machining to meet specific design requirements.

4. How do T-shaped aluminum extrusions compare to other materials?

T-shaped aluminum extrusions are lighter and more corrosion-resistant than steel, making them ideal for applications where weight reduction is crucial.

5. Are T-shaped aluminum extrusions environmentally friendly?

Yes, aluminum is 100% recyclable, making T-shaped aluminum extrusions an environmentally friendly choice for various applications.