Content Menu

● Introduction

● Understanding T-Slot Aluminum Extrusions

>> Key Features of 2020 T-Slot Aluminum Extrusions

● Applications of 2020 T-Slot Aluminum Extrusions

>> Industrial Automation

>> Workstations and Benches

>> Machine Guards and Safety Enclosures

>> Display and Exhibit Stands

>> Robotics and Prototyping

>> Furniture Design

>> DIY Projects and Home Improvement

>> Agricultural Equipment

>> Transportation and Logistics

>> Educational Projects

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using 2020 T-slot aluminum extrusions?

>> 2. Can T-slot aluminum extrusions be used outdoors?

>> 3. How do I assemble structures using T-slot aluminum extrusions?

>> 4. What industries commonly use 2020 T-slot aluminum extrusions?

>> 5. Are there any limitations to using T-slot aluminum extrusions?

Introduction

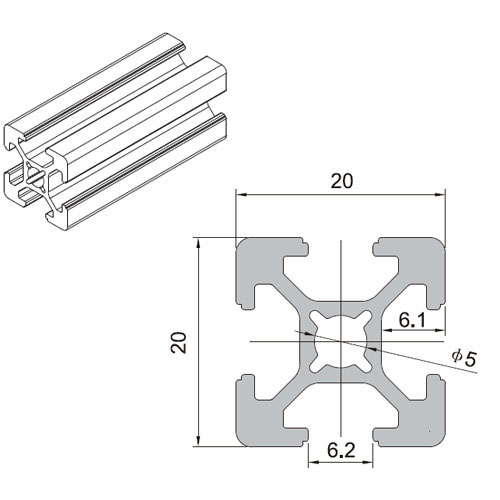

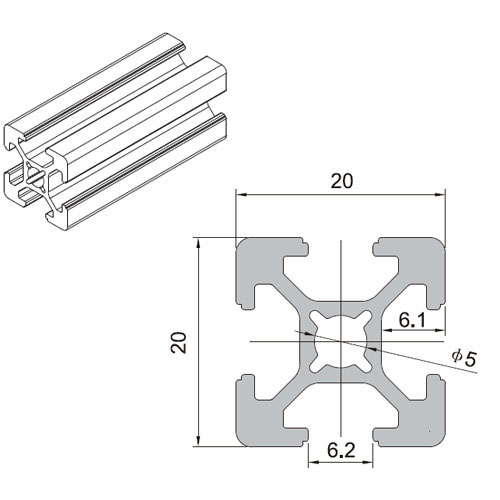

T-slot aluminum extrusions have become a staple in various industries due to their versatility, strength, and ease of use. Among the many sizes available, the 2020 T-slot aluminum extrusion, which measures 20mm x 20mm, is particularly popular. This article explores the numerous applications that benefit from 2020 T-slot aluminum extrusions, highlighting their advantages and providing insights into how they can be utilized effectively.

Understanding T-Slot Aluminum Extrusions

T-slot aluminum extrusions are profiles that feature a "T" shaped slot along their length. This design allows for easy assembly and disassembly of structures without the need for welding or complex fasteners. The 2020 profile is particularly favored for its balance of strength and weight, making it suitable for a wide range of applications.

Key Features of 2020 T-Slot Aluminum Extrusions

1. Modularity: The modular nature of T-slot extrusions allows for the creation of custom structures tailored to specific needs.

2. Lightweight: Aluminum is a lightweight material, making it ideal for portable applications.

3. Corrosion Resistance: Aluminum naturally resists corrosion, ensuring longevity in various environments.

4. Ease of Assembly: The T-slot design allows for quick and easy assembly using standard fasteners and connectors.

Applications of 2020 T-Slot Aluminum Extrusions

Industrial Automation

One of the most significant applications of 2020 T-slot aluminum extrusions is in industrial automation. These extrusions are used to build frames for machines, conveyor systems, and robotic arms. Their lightweight yet sturdy nature allows for the construction of complex systems that can withstand the rigors of industrial environments. The ability to easily modify and expand these structures makes them ideal for rapidly changing production needs.

Workstations and Benches

2020 T-slot aluminum extrusions are commonly used to create custom workstations and benches. The modular design allows for the easy adjustment of height and configuration, making it possible to design workspaces that meet specific ergonomic and functional requirements. This adaptability is particularly beneficial in environments where multiple users may require different setups throughout the day.

Machine Guards and Safety Enclosures

Safety is paramount in any industrial setting. T-slot aluminum extrusions can be used to construct machine guards and safety enclosures that protect workers from moving parts and hazardous materials. The ability to create transparent panels using polycarbonate or acrylic sheets in conjunction with the aluminum frame enhances visibility while maintaining safety. This combination ensures that operators can monitor machinery without compromising their safety.

Display and Exhibit Stands

In retail and exhibition environments, 2020 T-slot aluminum extrusions are used to create display stands and exhibit booths. Their sleek appearance and customizable nature allow businesses to design attractive displays that can be easily modified for different products or events. This flexibility is crucial for businesses that frequently change their offerings or participate in various trade shows.

Robotics and Prototyping

The robotics industry benefits significantly from the use of 2020 T-slot aluminum extrusions. They are ideal for building prototypes and frames for robotic systems due to their lightweight and strong properties. Engineers can quickly assemble and modify designs, facilitating rapid prototyping and testing. This capability is essential in a field where innovation and speed are critical to staying competitive.

Furniture Design

The furniture industry has also embraced T-slot aluminum extrusions for creating modern, minimalist furniture designs. From tables to shelving units, the ability to customize dimensions and configurations allows designers to create unique pieces that fit specific spaces. This trend towards modular furniture is gaining popularity as consumers seek adaptable solutions for their homes and offices.

DIY Projects and Home Improvement

For DIY enthusiasts, 2020 T-slot aluminum extrusions offer endless possibilities. They can be used to build everything from custom shelving units to home automation systems. The ease of assembly and disassembly makes it simple for hobbyists to experiment with different designs. This accessibility encourages creativity and innovation among individuals looking to personalize their living spaces.

Agricultural Equipment

In agriculture, T-slot aluminum extrusions are used to create frames for various equipment, including greenhouses and irrigation systems. Their resistance to corrosion and lightweight nature make them ideal for outdoor applications. Farmers can construct durable structures that withstand the elements while providing the necessary support for their operations.

Transportation and Logistics

In the transportation sector, 2020 T-slot aluminum extrusions are used to build custom racks and storage solutions for vehicles. Their lightweight design helps reduce overall vehicle weight while providing strong support for cargo. This efficiency is particularly important in logistics, where weight savings can lead to significant cost reductions in fuel and transportation.

Educational Projects

Educational institutions often use 2020 T-slot aluminum extrusions for STEM projects and robotics competitions. The ability to quickly assemble and modify structures encourages creativity and innovation among students. By providing hands-on experience with these materials, educators can foster a deeper understanding of engineering principles and design processes.

Conclusion

The versatility of 2020 T-slot aluminum extrusions makes them an invaluable resource across various industries. From industrial automation to DIY projects, their lightweight, modular design allows for endless possibilities. As technology continues to evolve, the applications for T-slot aluminum extrusions will undoubtedly expand, making them a staple in modern manufacturing and design.

Frequently Asked Questions

1. What are the main advantages of using 2020 T-slot aluminum extrusions?

The main advantages include their lightweight nature, modularity, ease of assembly, and corrosion resistance. These features make them suitable for a wide range of applications across different industries.

2. Can T-slot aluminum extrusions be used outdoors?

Yes, aluminum is naturally resistant to corrosion, making T-slot extrusions suitable for outdoor applications. This durability ensures that structures built with these extrusions can withstand various environmental conditions.

3. How do I assemble structures using T-slot aluminum extrusions?

Structures can be assembled using standard fasteners and connectors, allowing for quick and easy modifications. The T-slot design facilitates the attachment of various components, making it simple to create custom configurations.

4. What industries commonly use 2020 T-slot aluminum extrusions?

Industries such as manufacturing, robotics, furniture design, agriculture, and education commonly utilize T-slot aluminum extrusions. Their versatility allows them to be adapted for numerous applications across these sectors.

5. Are there any limitations to using T-slot aluminum extrusions?

While T-slot extrusions are versatile, they may not be suitable for applications requiring extreme strength or heavy load-bearing without proper design considerations. It is essential to evaluate the specific requirements of each project to ensure that the chosen materials are appropriate.