Content Menu

● Understanding 1/4 Inch Double Angle Aluminum Extrusion

● Key Benefits of 1/4 Inch Double Angle Aluminum Extrusion

● Ideal Applications for 1/4 Inch Double Angle Aluminum Extrusion

>> Structural Support

>> Framing Systems

>> Railing and Fencing

>> Automotive Applications

>> Machinery and Equipment

>> Signage and Displays

>> HVAC Systems

>> Marine Applications

>> Furniture Design

>> Custom Projects

● Additional Applications and Innovations

● Conclusion

● Frequently Asked Questions

>> 1. What is the weight capacity of 1/4 inch double angle aluminum extrusion?

>> 2. Can 1/4 inch double angle aluminum extrusions be painted?

>> 3. How do I cut 1/4 inch double angle aluminum extrusion?

>> 4. Are 1/4 inch double angle aluminum extrusions resistant to corrosion?

>> 5. What tools are needed for assembling projects with aluminum extrusions?

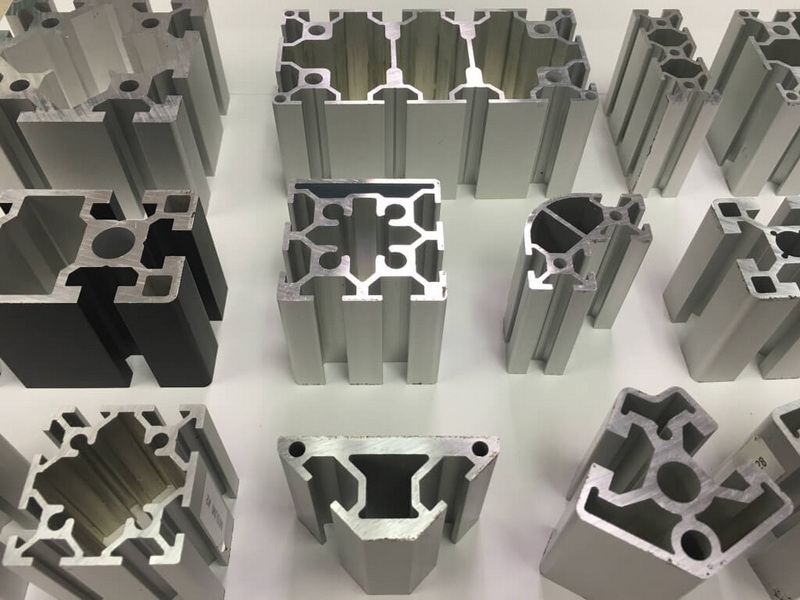

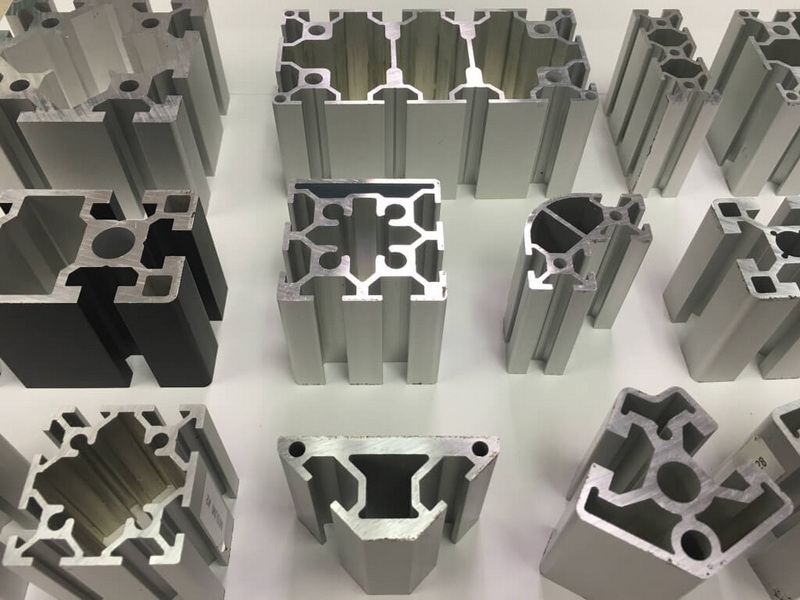

Aluminum extrusions are widely recognized for their versatility and strength, making them a popular choice in various industries. Among the different types of aluminum extrusions, the 1/4 inch double angle aluminum extrusion stands out due to its unique shape and structural properties. This article explores the ideal applications for 1/4 inch double angle aluminum extrusions, highlighting their benefits, uses, and the reasons behind their popularity.

Understanding 1/4 Inch Double Angle Aluminum Extrusion

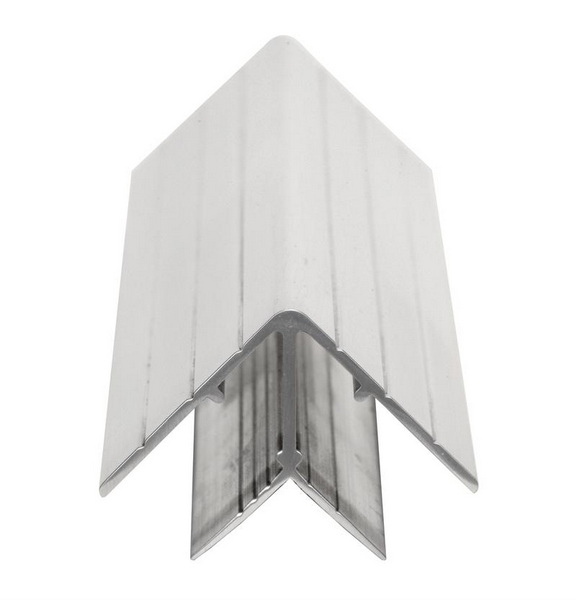

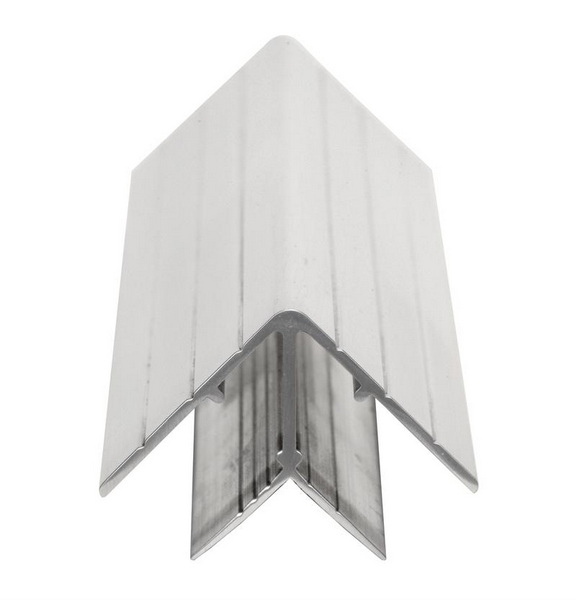

Before diving into specific applications, it's essential to understand what a 1/4 inch double angle aluminum extrusion is. This type of extrusion features two legs that form a right angle, creating an L-shaped profile. The "1/4 inch" designation refers to the thickness of the material, which provides a balance between strength and weight. The double angle design allows for enhanced structural integrity, making it suitable for various applications.

Key Benefits of 1/4 Inch Double Angle Aluminum Extrusion

1. Lightweight and Durable: Aluminum is known for its lightweight properties, which makes it easier to handle and install. Despite its lightness, aluminum is incredibly strong and resistant to corrosion, ensuring longevity in various environments.

2. Versatility: The double angle design allows for multiple configurations, making it suitable for a wide range of applications, from structural support to decorative elements.

3. Ease of Fabrication: Aluminum extrusions can be easily cut, drilled, and shaped, allowing for customization to meet specific project requirements.

4. Cost-Effective: Compared to other materials, aluminum extrusions offer a cost-effective solution for many applications, especially when considering their durability and low maintenance needs.

5. Aesthetic Appeal: The sleek appearance of aluminum extrusions can enhance the visual appeal of a project, making them suitable for both functional and decorative uses.

Ideal Applications for 1/4 Inch Double Angle Aluminum Extrusion

Structural Support

One of the primary applications of 1/4 inch double angle aluminum extrusion is in structural support. Its robust design makes it ideal for use in frameworks, brackets, and supports in various construction projects. Whether used in residential buildings, commercial structures, or industrial facilities, these extrusions provide the necessary strength to support loads while maintaining a lightweight profile.

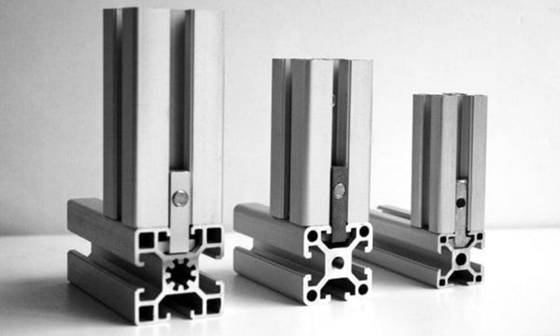

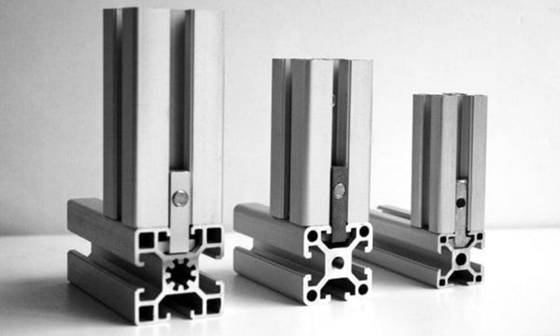

Framing Systems

In the realm of framing systems, 1/4 inch double angle aluminum extrusions are commonly used to create the skeleton of structures. They can be employed in the construction of walls, roofs, and even furniture. The ability to connect multiple extrusions allows for the creation of complex shapes and designs, making them a favorite among architects and designers.

Railing and Fencing

Aluminum extrusions are also popular in the manufacturing of railings and fencing. The 1/4 inch double angle design provides a sturdy framework for safety railings in commercial buildings, balconies, and staircases. Additionally, they can be used in decorative fencing applications, offering both security and aesthetic appeal.

Automotive Applications

In the automotive industry, weight reduction is crucial for improving fuel efficiency. 1/4 inch double angle aluminum extrusions are used in various automotive components, including frames, brackets, and supports. Their lightweight nature helps manufacturers create vehicles that are both strong and efficient.

Machinery and Equipment

Many types of machinery and equipment utilize 1/4 inch double angle aluminum extrusions for structural components. These extrusions can be found in conveyor systems, assembly lines, and other industrial applications where strength and durability are essential. Their resistance to corrosion also makes them suitable for use in environments where exposure to moisture is a concern.

Signage and Displays

The advertising and retail industries often use 1/4 inch double angle aluminum extrusions for signage and display systems. Their ability to be easily cut and shaped allows for the creation of custom signs that can withstand outdoor conditions. Additionally, their sleek appearance enhances the overall look of promotional displays.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, aluminum extrusions are used for ductwork and framing. The lightweight nature of 1/4 inch double angle aluminum extrusions makes them easy to install, while their strength ensures that they can handle the necessary airflow and pressure.

Marine Applications

The marine industry benefits from the use of aluminum extrusions due to their resistance to corrosion and lightweight properties. 1/4 inch double angle aluminum extrusions can be found in boat frames, railings, and other structural components, providing strength without adding excessive weight.

Furniture Design

In modern furniture design, aluminum extrusions are increasingly popular for creating sleek and contemporary pieces. The 1/4 inch double angle design can be used in the construction of tables, chairs, and shelving units, providing both strength and aesthetic appeal.

Custom Projects

Finally, one of the most significant advantages of 1/4 inch double angle aluminum extrusions is their adaptability for custom projects. Whether for DIY enthusiasts or professional fabricators, these extrusions can be tailored to meet specific needs, making them ideal for a wide range of applications.

Additional Applications and Innovations

As industries evolve, the applications for 1/4 inch double angle aluminum extrusions continue to expand. Innovations in manufacturing processes and design techniques have led to new uses in various fields. For instance, in the renewable energy sector, these extrusions are being utilized in the construction of solar panel frames and wind turbine supports. Their lightweight and durable nature makes them an excellent choice for supporting renewable energy technologies.

In the realm of robotics and automation, 1/4 inch double angle aluminum extrusions are increasingly used to create frames for robotic arms and automated systems. Their ability to be easily assembled and modified allows engineers to design and build complex systems that can adapt to various tasks.

Moreover, the rise of modular construction techniques has further increased the demand for aluminum extrusions. The 1/4 inch double angle design is particularly well-suited for modular building systems, where components can be prefabricated and assembled on-site, reducing construction time and costs.

Conclusion

The versatility of 1/4 inch double angle aluminum extrusions makes them an excellent choice for various applications across multiple industries. From structural support to decorative elements, their lightweight yet durable nature allows for innovative designs and solutions. As industries continue to seek materials that offer both strength and efficiency, aluminum extrusions will undoubtedly remain a popular choice.

Frequently Asked Questions

1. What is the weight capacity of 1/4 inch double angle aluminum extrusion?

The weight capacity depends on the specific design and application. Generally, they are strong enough to support significant loads, making them suitable for structural applications.

2. Can 1/4 inch double angle aluminum extrusions be painted?

Yes, aluminum extrusions can be painted or anodized to enhance their appearance and provide additional protection against corrosion.

3. How do I cut 1/4 inch double angle aluminum extrusion?

You can use a miter saw or a band saw with a fine-toothed blade designed for cutting metal. Ensure to wear safety gear while cutting.

4. Are 1/4 inch double angle aluminum extrusions resistant to corrosion?

Yes, aluminum is naturally resistant to corrosion, making it an excellent choice for outdoor and marine applications.

5. What tools are needed for assembling projects with aluminum extrusions?

Common tools include a drill, saw, measuring tape, and fasteners such as screws or bolts designed for aluminum.