Content Menu

● Understanding H Channel Aluminum Extrusions

>> Key Properties of H Channel Aluminum Extrusions

● Applications of H Channel Aluminum Extrusions

>> 1. Construction and Architecture

>> 2. Automotive Industry

>> 3. Aerospace Applications

>> 4. Industrial Equipment

>> 5. Furniture and Interior Design

>> 6. Signage and Displays

>> 7. Marine Applications

>> 8. Renewable Energy

>> 9. Robotics and Automation

>> 10. HVAC Systems

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using H channel aluminum extrusions?

>> 2. In which industries are H channel aluminum extrusions commonly used?

>> 3. Can H channel aluminum extrusions be customized?

>> 4. How do H channel aluminum extrusions compare to other materials?

>> 5. What is the typical lifespan of H channel aluminum extrusions?

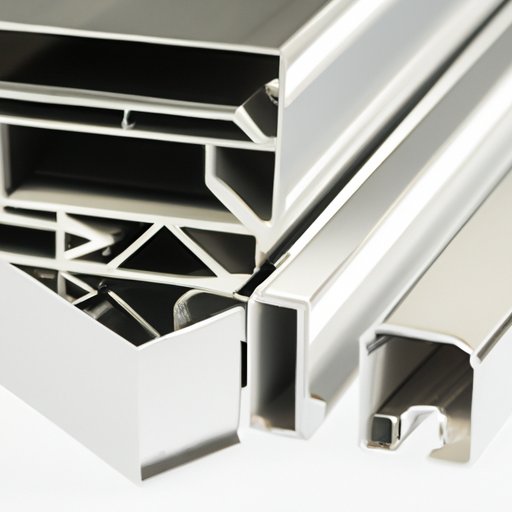

H channel aluminum extrusions are versatile structural components widely used in various industries due to their unique properties and design flexibility. This article explores the applications best suited for H channel aluminum extrusions, highlighting their benefits, characteristics, and the industries that utilize them.

Understanding H Channel Aluminum Extrusions

H channel aluminum extrusions are shaped like the letter "H," providing excellent strength and stability. They are made from aluminum, a lightweight yet durable material that resists corrosion and is easy to work with. The design of H channels allows for efficient load distribution, making them ideal for structural applications.

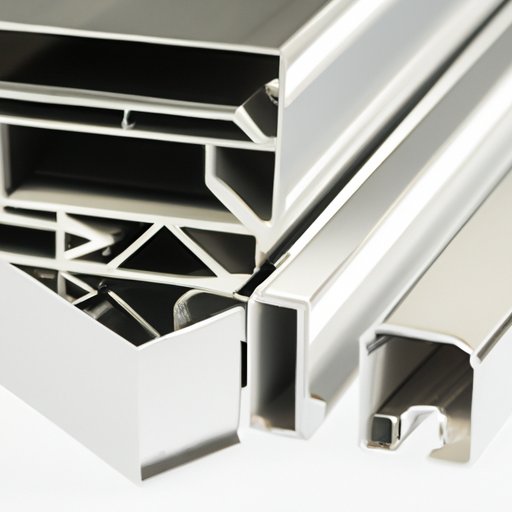

Key Properties of H Channel Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making H channel extrusions easier to handle and install.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, preventing rust and degradation over time.

3. High Strength-to-Weight Ratio: H channel extrusions provide excellent strength while maintaining a low weight, making them suitable for various applications.

4. Versatility: They can be easily cut, shaped, and joined, allowing for customization in design and application.

5. Aesthetic Appeal: The smooth finish of aluminum extrusions can enhance the visual appeal of structures and products.

Applications of H Channel Aluminum Extrusions

1. Construction and Architecture

H channel aluminum extrusions are commonly used in construction and architectural applications. They serve as structural supports in buildings, bridges, and other infrastructures. Their lightweight nature reduces the overall weight of structures, making them easier to transport and install.

In architectural designs, H channels can be used for window frames, curtain walls, and roofing systems. Their ability to withstand environmental factors while maintaining structural integrity makes them a preferred choice for modern buildings. The use of H channel extrusions in construction not only enhances the durability of structures but also contributes to energy efficiency by allowing for better insulation and thermal performance.

2. Automotive Industry

The automotive industry utilizes H channel aluminum extrusions for various components, including chassis, frames, and body panels. The lightweight nature of aluminum helps improve fuel efficiency and performance while reducing emissions.

H channel extrusions are also used in the manufacturing of electric vehicles, where weight reduction is crucial for maximizing battery efficiency and range. The automotive sector benefits from the recyclability of aluminum, making it an environmentally friendly choice. As manufacturers strive to meet stricter emissions regulations, the demand for lightweight materials like H channel aluminum extrusions continues to grow.

3. Aerospace Applications

In the aerospace sector, H channel aluminum extrusions are used in aircraft structures, including fuselages, wings, and support frames. The high strength-to-weight ratio of aluminum is essential for ensuring safety and performance in flight.

The corrosion resistance of aluminum is particularly beneficial in aerospace applications, where components are exposed to harsh environmental conditions. Additionally, the ability to fabricate complex shapes and sizes allows for innovative designs that enhance aerodynamics and fuel efficiency. As the aerospace industry continues to evolve, the use of H channel aluminum extrusions is expected to expand, particularly in the development of lighter and more efficient aircraft.

4. Industrial Equipment

H channel aluminum extrusions are widely used in the manufacturing of industrial equipment and machinery. They provide structural support for conveyor systems, workstations, and assembly lines.

Their versatility allows for easy customization, enabling manufacturers to create equipment tailored to specific operational needs. The lightweight nature of H channel extrusions also contributes to improved efficiency in manufacturing processes, as it reduces the overall weight of machinery and equipment. Furthermore, the ease of assembly and disassembly makes maintenance and upgrades more manageable, enhancing productivity in industrial settings.

5. Furniture and Interior Design

In furniture design, H channel aluminum extrusions are used for creating modern and sleek furniture pieces. They can be found in tables, chairs, and shelving units, providing both structural support and aesthetic appeal.

The lightweight nature of aluminum makes it easy to move and rearrange furniture, while the durability ensures longevity. Designers appreciate the clean lines and contemporary look that H channel extrusions offer, allowing for innovative designs that can fit various interior styles. Additionally, the ability to anodize or powder-coat aluminum provides endless possibilities for color and finish, further enhancing the visual appeal of furniture.

6. Signage and Displays

H channel aluminum extrusions are commonly used in signage and display systems. Their strength and stability make them ideal for supporting large signs, banners, and promotional displays.

The ability to customize H channels allows for creative designs that enhance visibility and attract attention. In retail environments, effective signage is crucial for guiding customers and promoting products. H channel extrusions provide a reliable framework for illuminated signs, ensuring they remain secure and visually appealing.

7. Marine Applications

In the marine industry, H channel aluminum extrusions are used in boat construction and marine equipment. Their corrosion resistance is crucial for withstanding exposure to saltwater and harsh weather conditions.

H channels can be found in boat frames, railings, and other structural components, ensuring safety and durability on the water. The lightweight nature of aluminum also contributes to improved fuel efficiency in marine vessels, making it a preferred choice for boat builders. As the demand for recreational and commercial boating continues to rise, the use of H channel aluminum extrusions in marine applications is expected to grow.

8. Renewable Energy

H channel aluminum extrusions play a role in renewable energy applications, particularly in solar panel mounting systems. Their lightweight and durable nature allows for efficient installation and support of solar panels.

The use of aluminum in renewable energy systems contributes to sustainability efforts by reducing the overall weight and improving efficiency. As the world shifts towards cleaner energy sources, the demand for reliable and efficient mounting solutions will continue to increase. H channel extrusions provide a robust framework for solar installations, ensuring they can withstand environmental stresses while maximizing energy capture.

9. Robotics and Automation

In robotics and automation, H channel aluminum extrusions are used to create frames and structures for robotic systems. Their strength and lightweight properties allow for precise movements and stability.

The ability to customize H channels enables engineers to design robotic systems tailored to specific tasks and environments. As automation becomes increasingly prevalent in various industries, the demand for lightweight and durable materials like H channel aluminum extrusions will continue to rise. These extrusions provide the necessary support for complex robotic systems, enhancing their performance and reliability.

10. HVAC Systems

H channel aluminum extrusions are utilized in heating, ventilation, and air conditioning (HVAC) systems. They provide structural support for ductwork and other components, ensuring efficient airflow and temperature control.

The lightweight nature of aluminum makes installation easier, while its durability ensures long-lasting performance. In modern buildings, efficient HVAC systems are essential for maintaining comfort and energy efficiency. H channel extrusions contribute to the overall effectiveness of these systems by providing a reliable framework for ductwork and ventilation components.

Conclusion

H channel aluminum extrusions are essential components in various industries, offering a combination of strength, lightweight properties, and versatility. Their applications range from construction and automotive to aerospace and renewable energy, making them a popular choice for engineers and designers. As technology advances, the use of H channel aluminum extrusions is expected to grow, further enhancing their role in modern manufacturing and design.

Frequently Asked Questions

1. What are the advantages of using H channel aluminum extrusions?

H channel aluminum extrusions offer lightweight properties, corrosion resistance, high strength-to-weight ratio, versatility, and aesthetic appeal. These advantages make them suitable for a wide range of applications across various industries.

2. In which industries are H channel aluminum extrusions commonly used?

They are commonly used in construction, automotive, aerospace, industrial equipment, furniture design, signage, marine applications, renewable energy, robotics, and HVAC systems. Their versatility allows them to meet the needs of diverse sectors.

3. Can H channel aluminum extrusions be customized?

Yes, H channel aluminum extrusions can be easily cut, shaped, and joined to meet specific design and application requirements. This customization capability makes them ideal for tailored solutions in various projects.

4. How do H channel aluminum extrusions compare to other materials?

H channel aluminum extrusions are lighter and more corrosion-resistant than steel, making them a preferred choice for many applications. Their high strength-to-weight ratio also contributes to improved performance in structural applications.

5. What is the typical lifespan of H channel aluminum extrusions?

With proper maintenance and care, H channel aluminum extrusions can last for many years, often exceeding the lifespan of other materials in similar applications. Their durability and resistance to environmental factors contribute to their longevity.