Content Menu

● Understanding Aluminum Extrusion 4040

● Benefits of Aluminum Extrusion 4040

● Applications of Aluminum Extrusion 4040

>> Industrial Automation

>> Workstations and Benches

>> Display Stands and Racks

>> Enclosures and Frames

>> Furniture Design

>> Transportation and Automotive

>> Solar Panel Mounting Systems

>> Robotics and Prototyping

>> Home Improvement Projects

>> Art Installations

● Design Considerations for Aluminum Extrusion 4040

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion 4040?

>> 2. What are the advantages of using aluminum extrusion?

>> 3. Can aluminum extrusion 4040 be used for outdoor applications?

>> 4. How can I cut aluminum extrusion 4040?

>> 5. Is aluminum extrusion 4040 suitable for DIY projects?

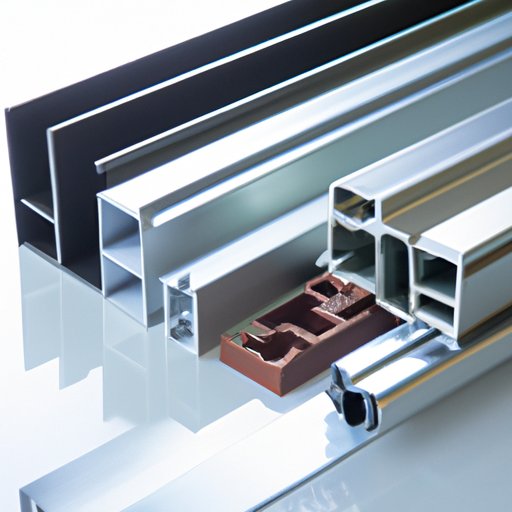

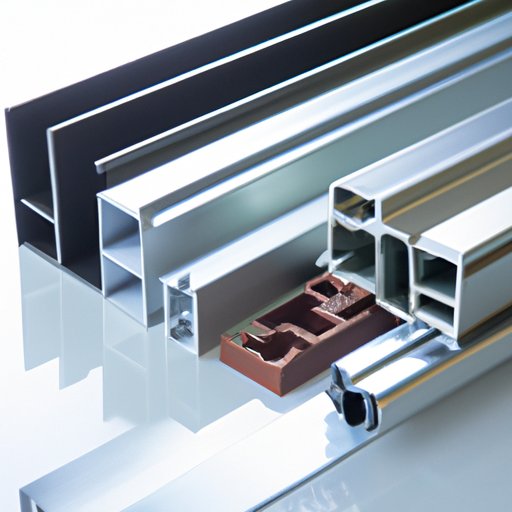

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various profiles available, the 4040 aluminum extrusion is particularly popular due to its versatility and strength. This article explores the applications best suited for aluminum extrusion 4040, highlighting its benefits, design considerations, and practical uses across different industries.

Understanding Aluminum Extrusion 4040

Aluminum extrusion 4040 refers to a specific size of aluminum profile that measures 40mm x 40mm in cross-section. This square profile is part of the T-slot aluminum extrusion family, which features grooves along its length. These grooves allow for easy assembly and integration with other components, making it an ideal choice for a wide range of applications.

Benefits of Aluminum Extrusion 4040

1. Lightweight and Strong: Aluminum is known for its excellent strength-to-weight ratio. The 4040 profile is robust enough to support heavy loads while remaining lightweight, making it suitable for various structural applications.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion. This property is particularly beneficial in environments where moisture or chemicals are present.

3. Ease of Assembly: The T-slot design allows for quick and easy assembly without the need for specialized tools. This feature is advantageous for prototyping and modular construction.

4. Versatility: The 4040 profile can be used in numerous applications, from industrial machinery to DIY projects. Its adaptability makes it a favorite among engineers and hobbyists alike.

5. Customizability: Aluminum extrusion can be easily cut, drilled, and machined to meet specific project requirements. This flexibility allows for tailored solutions in various applications.

Applications of Aluminum Extrusion 4040

Industrial Automation

One of the primary applications of aluminum extrusion 4040 is in industrial automation. The profile is commonly used to construct frames for automated machinery, conveyor systems, and robotic arms. Its strength and lightweight nature make it ideal for supporting moving parts while minimizing energy consumption. The modularity of the 4040 profile allows for easy reconfiguration of systems as production needs change.

Workstations and Benches

Aluminum extrusion 4040 is frequently used to build workstations and benches in manufacturing and assembly environments. The modular design allows for easy customization of the workspace, enabling users to create ergonomic setups tailored to their specific tasks. Adjustable height workstations can be constructed using the 4040 profile, promoting better posture and comfort for workers.

Display Stands and Racks

Retail environments often utilize aluminum extrusion 4040 to create display stands and racks. The sleek appearance of aluminum, combined with its structural integrity, makes it an attractive choice for showcasing products while ensuring stability. The ability to easily modify and expand display setups is a significant advantage for retailers looking to adapt to changing inventory and promotional needs.

Enclosures and Frames

Aluminum extrusion 4040 is ideal for constructing enclosures and frames for electronic equipment, machinery, and sensitive components. The profile can be easily fitted with panels or glass, providing protection while allowing for ventilation and visibility. This application is particularly important in environments where dust and moisture can damage sensitive equipment.

Furniture Design

In the realm of furniture design, aluminum extrusion 4040 is increasingly popular for creating modern, minimalist furniture pieces. Its clean lines and ability to support various materials make it a favorite among designers looking to create functional yet stylish furniture. The lightweight nature of aluminum also allows for easy mobility of furniture pieces, making them suitable for dynamic spaces.

Transportation and Automotive

The transportation industry benefits from aluminum extrusion 4040 in the construction of lightweight frames for vehicles, trailers, and other transport equipment. The reduced weight contributes to improved fuel efficiency without compromising strength. Additionally, aluminum's resistance to corrosion makes it an ideal material for components exposed to the elements.

Solar Panel Mounting Systems

Aluminum extrusion 4040 is also used in solar panel mounting systems. Its corrosion resistance and strength make it suitable for outdoor applications, ensuring that solar panels are securely mounted and can withstand environmental stresses. The modular nature of the 4040 profile allows for easy adjustments and expansions of solar installations as energy needs grow.

Robotics and Prototyping

In robotics, aluminum extrusion 4040 is often used to build frames for robotic arms and mobile platforms. Its ease of assembly and customization allows engineers to quickly prototype and iterate designs. The ability to create lightweight yet strong structures is crucial in robotics, where performance and efficiency are paramount.

Home Improvement Projects

DIY enthusiasts frequently use aluminum extrusion 4040 for home improvement projects. Whether building custom shelving, creating a greenhouse frame, or designing unique furniture, the profile's versatility makes it a go-to choice for many projects. The ease of assembly and modification allows hobbyists to experiment with different designs and functionalities.

Art Installations

Artists and designers are increasingly incorporating aluminum extrusion 4040 into their work. Its modern aesthetic and structural capabilities allow for innovative art installations that challenge traditional forms. The ability to create complex shapes and structures with aluminum extrusion opens up new avenues for artistic expression.

Design Considerations for Aluminum Extrusion 4040

When working with aluminum extrusion 4040, several design considerations should be taken into account:

1. Load Requirements: Determine the load-bearing requirements of your application to ensure the 4040 profile can adequately support the intended weight. This is crucial in industrial applications where safety and reliability are paramount.

2. Environmental Factors: Consider the environment in which the aluminum extrusion will be used. If exposed to harsh conditions, additional protective coatings may be necessary. For outdoor applications, anodizing or powder coating can enhance corrosion resistance.

3. Assembly Method: Plan the assembly method in advance. The T-slot design allows for various joining techniques, including brackets, fasteners, and connectors. Understanding the best assembly method can streamline the construction process.

4. Customization Needs: Assess whether the profile needs to be cut or machined to fit specific dimensions. Aluminum extrusion can be easily modified to meet project requirements, allowing for precise fits in complex designs.

5. Aesthetic Preferences: Consider the visual impact of the aluminum extrusion in your design. The natural finish of aluminum can be enhanced with anodizing or powder coating for added color and protection. This is particularly important in applications where appearance is a key factor, such as furniture and display stands.

Conclusion

Aluminum extrusion 4040 is a versatile and robust solution for a wide range of applications across various industries. Its lightweight nature, strength, and ease of assembly make it an ideal choice for everything from industrial automation to furniture design. As technology advances and the demand for innovative solutions grows, the applications of aluminum extrusion 4040 will continue to expand, offering endless possibilities for engineers, designers, and DIY enthusiasts alike.

Frequently Asked Questions

1. What is aluminum extrusion 4040?

Aluminum extrusion 4040 is a specific aluminum profile measuring 40mm x 40mm, commonly used in various applications due to its strength and versatility.

2. What are the advantages of using aluminum extrusion?

Aluminum extrusion offers benefits such as lightweight strength, corrosion resistance, ease of assembly, and customizability.

3. Can aluminum extrusion 4040 be used for outdoor applications?

Yes, aluminum extrusion 4040 is suitable for outdoor applications due to its corrosion resistance, making it ideal for structures exposed to the elements.

4. How can I cut aluminum extrusion 4040?

Aluminum extrusion can be cut using standard saws, such as miter saws or band saws, equipped with appropriate blades for aluminum.

5. Is aluminum extrusion 4040 suitable for DIY projects?

Absolutely! Aluminum extrusion 4040 is popular among DIY enthusiasts for its versatility and ease of assembly, making it perfect for various home improvement projects.