Content Menu

● Understanding 90 Degree Aluminum Extrusions

● Benefits of Using 90 Degree Aluminum Extrusions

● Applications of 90 Degree Aluminum Extrusions

>> 1. Architectural Frameworks

>> 2. Industrial Machinery

>> 3. Furniture Design

>> 4. Display Systems

>> 5. Automotive Applications

>> 6. Transportation Solutions

>> 7. Solar Panel Mounting Systems

>> 8. Signage and Displays

● Installation Techniques for 90 Degree Aluminum Extrusions

● Innovations in 90 Degree Aluminum Extrusions

● Case Studies Highlighting Successful Applications

● Conclusion

● Related Questions

>> 1. What materials can be used alongside 90 degree aluminum extrusions?

>> 2. How do you maintain structures made from 90 degree aluminum extrusions?

>> 3. Can you customize 90 degree aluminum extrusions?

>> 4. What is the typical lifespan of products made from 90 degree aluminum extrusions?

>> 5. Are there any environmental benefits to using aluminum?

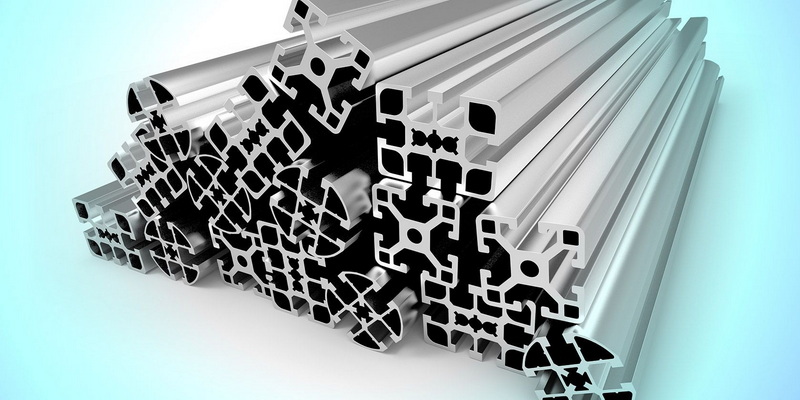

Aluminum extrusions have become a cornerstone in various industries due to their versatility, strength, and lightweight properties. Among these, 90 degree aluminum extrusions play a crucial role in applications that require precise angles and structural integrity. This article explores the best applications suited for 90 degree aluminum extrusions, highlighting their benefits, installation methods, and innovative uses across different sectors.

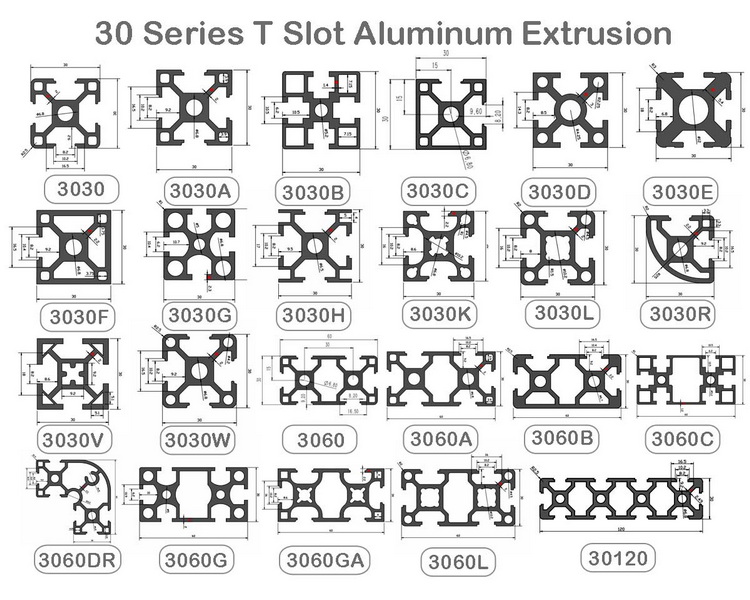

Understanding 90 Degree Aluminum Extrusions

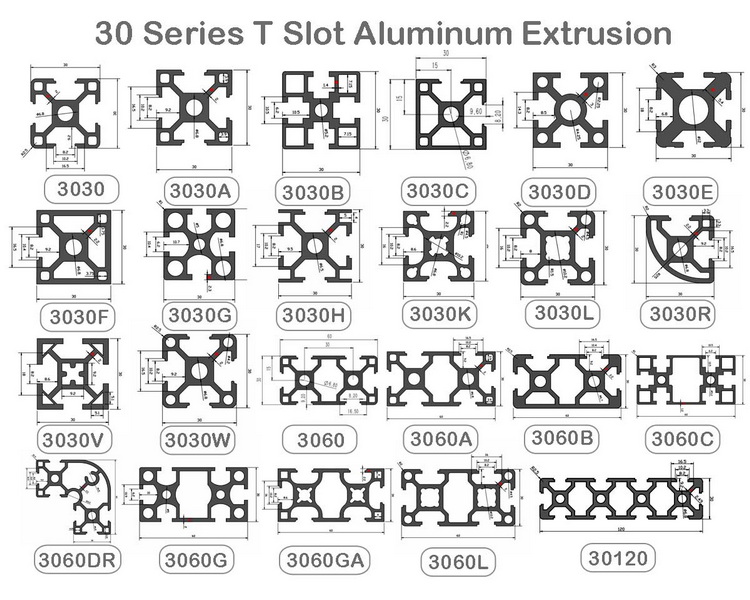

90 degree aluminum extrusions are specifically designed profiles that form a right angle. They can be used in various configurations and are often employed in framing systems, supports, and structural components. The unique properties of aluminum, such as corrosion resistance and ease of fabrication, make these extrusions ideal for both indoor and outdoor applications.

Benefits of Using 90 Degree Aluminum Extrusions

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and install. This feature is particularly beneficial in applications where weight reduction is crucial, such as in automotive and aerospace industries.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents rusting, making it suitable for outdoor use. This property extends the lifespan of structures and reduces maintenance costs.

- Versatility: These extrusions can be easily cut, drilled, or welded to fit specific project requirements. Their adaptability allows for innovative designs that can meet diverse engineering challenges.

- Aesthetic Appeal: The sleek finish of aluminum provides a modern look that enhances the overall design of structures. This aesthetic quality is particularly valued in architectural applications where visual impact is essential.

Applications of 90 Degree Aluminum Extrusions

1. Architectural Frameworks

One of the most common applications of 90 degree aluminum extrusions is in architectural frameworks. These extrusions are used to create window frames, door frames, and structural supports for buildings. Their ability to withstand environmental stress while maintaining aesthetic appeal makes them a popular choice among architects.

In modern architecture, the use of aluminum has expanded beyond traditional frameworks. Architects now utilize 90 degree aluminum extrusions to create intricate designs that incorporate glass elements or mixed materials. This allows for expansive views and natural light while maintaining structural integrity.

2. Industrial Machinery

In industrial settings, 90 degree aluminum extrusions are utilized in the construction of machinery frames and supports. Their strength-to-weight ratio allows for robust designs without adding unnecessary weight to the equipment. This is particularly important in industries where machinery must be mobile or easily reconfigured.

Additionally, the ease of assembly with these extrusions means that maintenance and upgrades can be performed quickly without extensive downtime. Industries such as manufacturing and packaging benefit significantly from this flexibility.

3. Furniture Design

Modern furniture design increasingly incorporates aluminum extrusions due to their sleek appearance and durability. Designers use 90 degree aluminum extrusions to create unique furniture pieces that are both functional and stylish. From minimalist tables to modular shelving units, the possibilities are endless.

The lightweight nature of aluminum also means that furniture can be easily moved or rearranged without compromising stability. Furthermore, the ability to anodize or powder coat these extrusions allows designers to customize colors and finishes to match various interior styles.

4. Display Systems

Retail environments often utilize 90 degree aluminum extrusions in display systems. These extrusions provide a sturdy base for product displays while allowing for easy customization to fit various retail layouts. The clean lines of aluminum enhance product visibility and appeal.

Moreover, the modular nature of these display systems means they can be easily reconfigured for seasonal promotions or new product launches. Retailers appreciate this adaptability as it maximizes space usage while keeping displays fresh and engaging.

5. Automotive Applications

The automotive industry benefits from the lightweight nature of aluminum. 90 degree aluminum extrusions are used in car frames, supports, and even interior components to reduce overall vehicle weight while maintaining safety standards. This weight reduction contributes to improved fuel efficiency and performance.

Additionally, as manufacturers strive to meet stricter environmental regulations, the use of lightweight materials like aluminum becomes increasingly important in vehicle design. Innovations in extrusion technology continue to enhance the performance characteristics of these components.

6. Transportation Solutions

In transportation sectors such as railways and aviation, 90 degree aluminum extrusions are employed in structural components due to their strength and lightweight characteristics. They help enhance fuel efficiency while ensuring safety.

For instance, in rail systems, these extrusions can be found in train carriages where they provide necessary structural support without adding excessive weight. In aviation, they contribute to aircraft fuselage designs where every ounce counts towards fuel efficiency.

7. Solar Panel Mounting Systems

With the rise of renewable energy sources, 90 degree aluminum extrusions are increasingly used in solar panel mounting systems. Their durability ensures that solar panels remain securely positioned even under harsh weather conditions.

Aluminum's resistance to corrosion makes it an ideal choice for outdoor installations where exposure to moisture and varying temperatures can affect other materials' integrity over time. This reliability enhances the longevity of solar energy systems.

8. Signage and Displays

Outdoor signage often utilizes 90 degree aluminum extrusions due to their resistance to weathering and corrosion. They provide a robust framework for signs that need to withstand the elements while remaining visually appealing.

Businesses rely on durable signage not only for branding but also for safety information along highways or construction sites. The ability to customize these signs with various finishes adds further value.

Installation Techniques for 90 Degree Aluminum Extrusions

Proper installation is crucial for maximizing the benefits of 90 degree aluminum extrusions. Here are some key techniques:

- Cutting: Use a miter saw with a fine-tooth blade specifically designed for cutting aluminum to ensure clean edges. Accurate cuts are essential for achieving tight joints at right angles.

- Joining: Employ corner brackets or welding techniques to securely join pieces at right angles. For applications requiring disassembly or reconfiguration, using mechanical fasteners may be preferable over welding.

- Finishing: Anodizing or powder coating can enhance the appearance and corrosion resistance of the finished product. These treatments not only protect against wear but also allow for color customization that aligns with design aesthetics.

Innovations in 90 Degree Aluminum Extrusions

The industry continues to innovate with new designs and manufacturing techniques for 90 degree aluminum extrusions. Advances in technology have led to:

- Improved extrusion processes that allow for more complex shapes without compromising strength.

- Enhanced surface treatments that increase durability and aesthetics.

- Customization options that cater specifically to client needs; this includes bespoke lengths, shapes, and finishes tailored for unique projects.

Moreover, advancements in computer-aided design (CAD) software enable engineers to visualize how these components will fit into larger systems before production begins, reducing waste and optimizing material usage.

Case Studies Highlighting Successful Applications

To illustrate the versatility of 90 degree aluminum extrusions, consider some notable case studies:

1. High-Rise Residential Buildings: In several urban developments, architects have utilized these extrusions extensively in curtain wall systems due to their lightweight yet strong properties which allow for expansive glass facades without compromising structural integrity.

2. Modular Office Furniture Solutions: A leading office furniture manufacturer integrated custom-designed 90 degree aluminum extrusions into their modular workstations allowing businesses flexibility as they grow or change layouts over time while maintaining a modern aesthetic appeal.

3. Renewable Energy Projects: A solar farm project utilized these extrusions not only for mounting solar panels but also as part of its tracking system which adjusts panel angles throughout the day maximizing energy absorption efficiently across varying geographic locations.

Conclusion

The applications of 90 degree aluminum extrusions are vast and varied, spanning across architecture, industrial machinery, furniture design, transportation solutions, renewable energy systems, signage displays, and more. Their lightweight nature combined with exceptional strength makes them an ideal choice for numerous projects requiring precision and durability.

As industries continue to evolve towards more sustainable practices while demanding higher performance from materials used within their projects—such as reducing overall weight without sacrificing safety—aluminum remains at the forefront due its unique properties including recyclability which further enhances its environmental credentials compared against traditional materials like steel or plastics.

With ongoing innovations shaping future designs alongside increasing demand across diverse sectors—ranging from construction through automotive engineering—the potential uses for 90 degree aluminum extrusions will undoubtedly expand further solidifying their role as essential components within modern manufacturing processes today.

Related Questions

1. What materials can be used alongside 90 degree aluminum extrusions?

Aluminum can be combined with materials such as glass, wood, or plastics depending on the application requirements.

2. How do you maintain structures made from 90 degree aluminum extrusions?

Regular cleaning with mild soap and water is recommended; avoid harsh chemicals that may damage the finish.

3. Can you customize 90 degree aluminum extrusions?

Yes, many manufacturers offer custom extrusion services tailored to specific project needs.

4. What is the typical lifespan of products made from 90 degree aluminum extrusions?

With proper maintenance, products can last several decades due to aluminum's corrosion-resistant properties.

5. Are there any environmental benefits to using aluminum?

Yes, aluminum is recyclable without losing quality, making it an environmentally friendly material choice compared to others like steel or plastic.