Content Menu

● Understanding 4545 Aluminum Extrusion

>> Key Characteristics of 4545 Aluminum Extrusion

● Applications of 4545 Aluminum Extrusion

>> 1. Industrial Automation

>> 2. Workstations and Assembly Lines

>> 3. Machine Guards and Safety Barriers

>> 4. Robotics and Automation Systems

>> 5. Display and Exhibit Structures

>> 6. Furniture Design

>> 7. Transportation and Automotive Applications

>> 8. Construction and Architectural Applications

>> 9. Custom Machinery and Equipment

>> 10. 3D Printing and Prototyping

● Benefits of Using 4545 Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is the weight capacity of 4545 aluminum extrusion?

>> 2. Can 4545 aluminum extrusion be used outdoors?

>> 3. How do I cut 4545 aluminum extrusion?

>> 4. Is it easy to assemble structures using 4545 aluminum extrusion?

>> 5. What industries commonly use 4545 aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various profiles available, the 4545 aluminum extrusion is particularly popular due to its versatility and strength. This article explores the applications best suited for 4545 aluminum extrusion, highlighting its benefits, use cases, and the industries that rely on this material.

Understanding 4545 Aluminum Extrusion

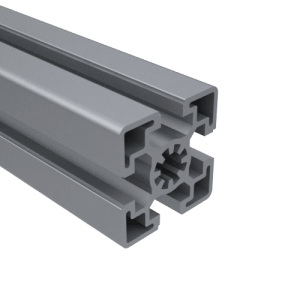

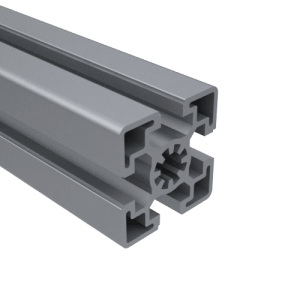

The term 4545 aluminum extrusion refers to a specific profile that measures 45mm by 45mm. This square profile features T-slots on all four sides, allowing for easy assembly and integration with various components. The T-slot design is particularly advantageous for creating modular structures, making it a favorite among engineers and designers.

Key Characteristics of 4545 Aluminum Extrusion

1. Strength and Durability: Aluminum is known for its high strength-to-weight ratio, making it an ideal choice for applications requiring robust materials without excessive weight.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion, making it suitable for both indoor and outdoor applications.

3. Lightweight: The lightweight nature of aluminum allows for easier handling and transportation, reducing overall project costs.

4. Versatility: The 4545 profile can be used in a wide range of applications, from structural frameworks to custom machinery.

Applications of 4545 Aluminum Extrusion

1. Industrial Automation

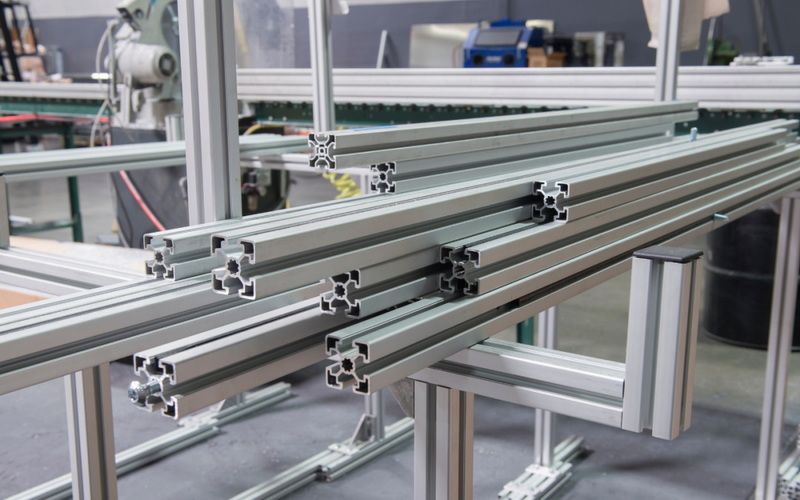

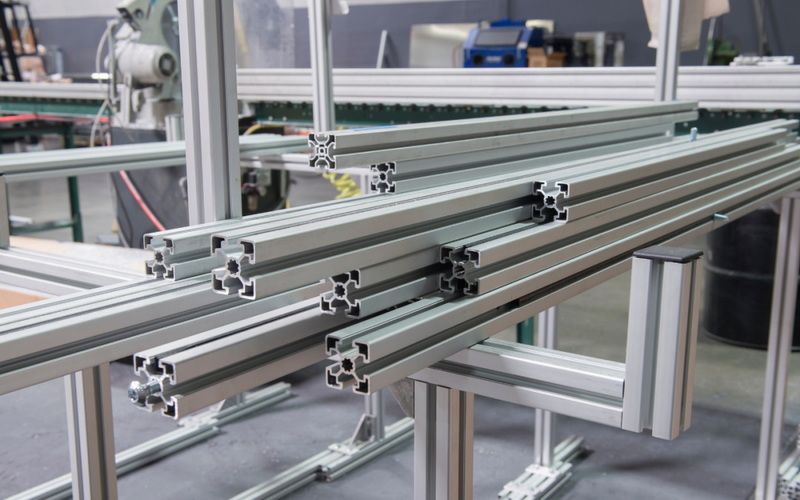

One of the most significant applications of 4545 aluminum extrusion is in industrial automation. The T-slot design allows for the easy assembly of frames, enclosures, and supports for various machinery. This flexibility enables manufacturers to create custom solutions tailored to their specific needs. For instance, companies can quickly adapt their production lines to accommodate new products or processes, enhancing efficiency and productivity.

2. Workstations and Assembly Lines

4545 aluminum extrusions are widely used to construct workstations and assembly lines. The modular nature of the T-slot profile allows for quick adjustments and reconfigurations, accommodating changes in workflow or product design. This adaptability is crucial in fast-paced manufacturing environments where efficiency is key. Workstations can be designed to fit specific tasks, ensuring that workers have the tools and space they need to perform their jobs effectively.

3. Machine Guards and Safety Barriers

Safety is paramount in industrial settings, and 4545 aluminum extrusion provides an effective solution for creating machine guards and safety barriers. The strength of the aluminum ensures that these structures can withstand impacts while maintaining visibility for operators. This is particularly important in environments where heavy machinery is in use, as it helps prevent accidents and injuries.

4. Robotics and Automation Systems

In the field of robotics, 4545 aluminum extrusion is often used to build frames and supports for robotic arms and automated systems. The lightweight yet sturdy nature of aluminum allows for precise movements and reduces the overall weight of the robotic systems, enhancing efficiency. This is especially beneficial in applications where speed and accuracy are critical, such as in assembly lines or packaging operations.

5. Display and Exhibit Structures

The versatility of 4545 aluminum extrusion makes it an excellent choice for creating display and exhibit structures. Whether for trade shows, retail environments, or museums, the ability to customize the design and easily assemble and disassemble the structures is a significant advantage. This flexibility allows businesses to create eye-catching displays that can be quickly set up and taken down, maximizing their investment in marketing and promotions.

6. Furniture Design

In recent years, aluminum extrusion has gained popularity in furniture design. The sleek appearance of 4545 aluminum profiles allows designers to create modern, minimalist furniture that is both functional and aesthetically pleasing. The modularity of the profiles also enables easy customization, allowing for unique designs that can adapt to different spaces and uses. This trend is particularly evident in office furniture, where adaptability and style are essential.

7. Transportation and Automotive Applications

The automotive industry utilizes 4545 aluminum extrusion for various components, including chassis, frames, and structural supports. The lightweight nature of aluminum contributes to fuel efficiency while maintaining the necessary strength for safety and performance. As the automotive industry moves towards lighter materials to improve fuel economy and reduce emissions, aluminum extrusion is becoming increasingly important.

8. Construction and Architectural Applications

In construction, 4545 aluminum extrusion is used for window frames, curtain walls, and other architectural elements. The corrosion resistance of aluminum makes it suitable for outdoor applications, ensuring longevity and durability. Architects and builders appreciate the aesthetic appeal of aluminum, which can be finished in various ways to match the design of a building.

9. Custom Machinery and Equipment

Many manufacturers rely on 4545 aluminum extrusion to create custom machinery and equipment. The ability to design and build specific components tailored to unique processes is a significant advantage in industries such as food processing, packaging, and pharmaceuticals. Custom solutions can enhance efficiency and productivity, allowing businesses to meet specific operational needs.

10. 3D Printing and Prototyping

The rise of 3D printing has also led to increased use of aluminum extrusion in prototyping. Designers can create frames and supports for 3D printers, ensuring stability and precision during the printing process. This application is particularly valuable in industries where rapid prototyping is essential for product development, allowing companies to bring new products to market faster.

Benefits of Using 4545 Aluminum Extrusion

- Cost-Effective: The modular nature of aluminum extrusion reduces material waste and labor costs, making it a cost-effective solution for various applications.

- Easy to Work With: The T-slot design allows for easy assembly and disassembly, enabling quick modifications and repairs.

- Aesthetic Appeal: The sleek appearance of aluminum profiles enhances the visual appeal of products and structures, making them suitable for public-facing applications.

Conclusion

The 4545 aluminum extrusion profile is a versatile and robust solution for a wide range of applications across various industries. Its strength, lightweight nature, and adaptability make it an ideal choice for everything from industrial automation to furniture design. As technology continues to advance, the applications for aluminum extrusion will likely expand, further solidifying its place as a critical material in modern manufacturing and design.

Frequently Asked Questions

1. What is the weight capacity of 4545 aluminum extrusion?

The weight capacity depends on the specific design and application, but 4545 aluminum extrusion is known for its high strength-to-weight ratio, making it suitable for heavy-duty applications.

2. Can 4545 aluminum extrusion be used outdoors?

Yes, aluminum has excellent corrosion resistance, making it suitable for outdoor applications.

3. How do I cut 4545 aluminum extrusion?

4545 aluminum extrusion can be cut using standard metal cutting tools, such as miter saws or band saws, equipped with appropriate blades for aluminum.

4. Is it easy to assemble structures using 4545 aluminum extrusion?

Yes, the T-slot design allows for easy assembly and disassembly, making it user-friendly for various applications.

5. What industries commonly use 4545 aluminum extrusion?

Industries such as manufacturing, automotive, construction, and robotics frequently utilize 4545 aluminum extrusion for its versatility and strength.