Content Menu

● Understanding 4060 Aluminum Extrusion

● Benefits of 4060 Aluminum Extrusion

● Applications of 4060 Aluminum Extrusion

>> Industrial Frameworks

>> Automation and Robotics

>> Workstations and Benches

>> Display and Retail Fixtures

>> Transportation and Automotive

>> Furniture Design

>> Custom Machinery

>> Greenhouses and Agricultural Structures

>> Signage and Displays

>> HVAC Systems

● Conclusion

● Frequently Asked Questions

>> 1. What is the weight capacity of 4060 aluminum extrusion?

>> 2. Can 4060 aluminum extrusion be used outdoors?

>> 3. How is 4060 aluminum extrusion assembled?

>> 4. What finishes are available for 4060 aluminum extrusion?

>> 5. Is 4060 aluminum extrusion recyclable?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various profiles available, the 4060 aluminum extrusion is particularly popular due to its versatility and strength. This article explores the applications best suited for 4060 aluminum extrusion, highlighting its benefits, uses in different industries, and why it is a preferred choice for many engineering and construction projects.

Understanding 4060 Aluminum Extrusion

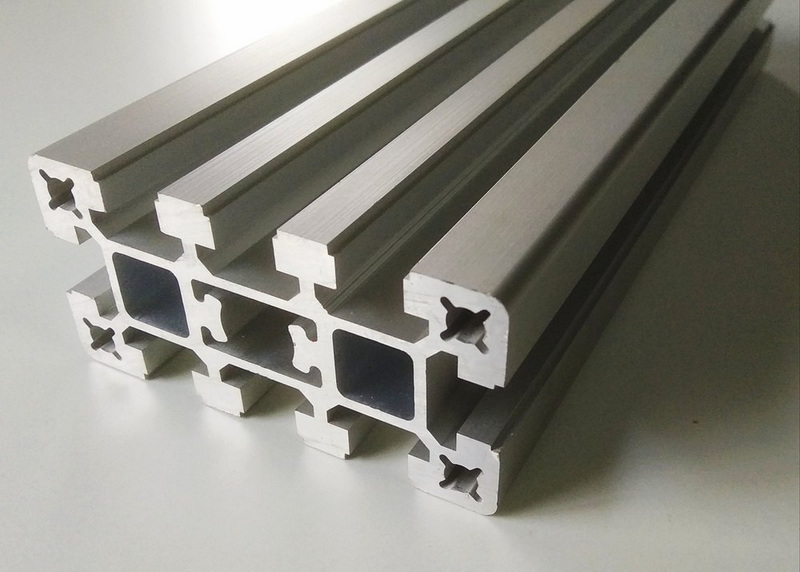

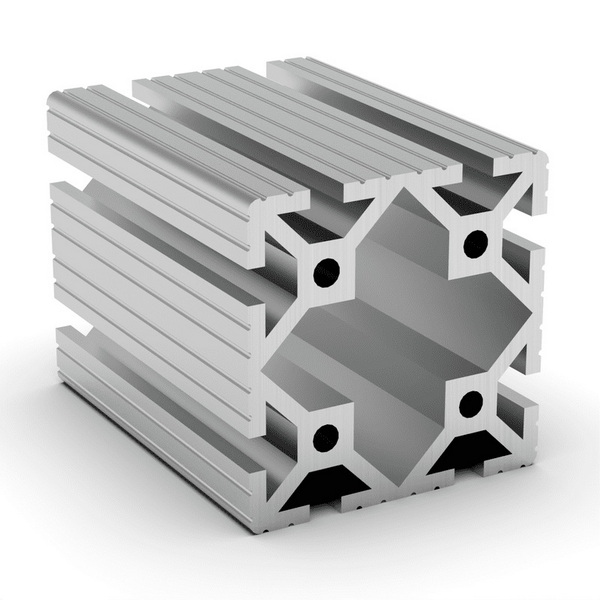

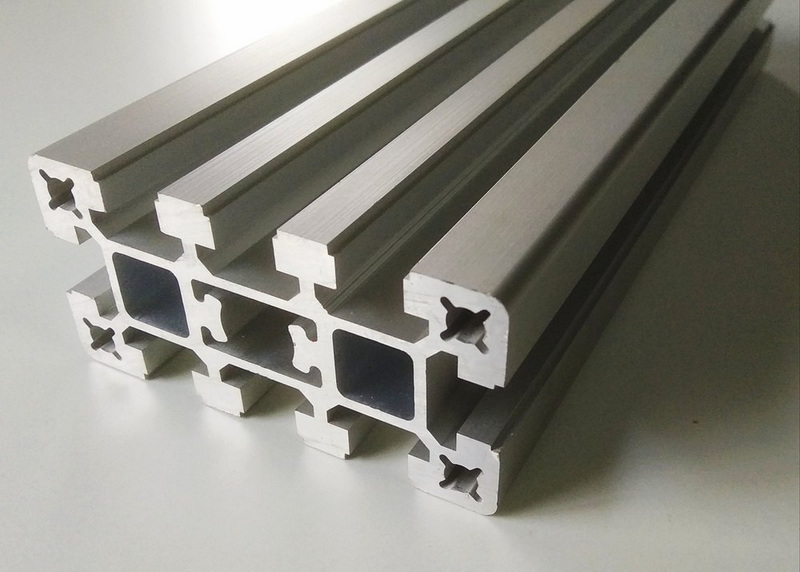

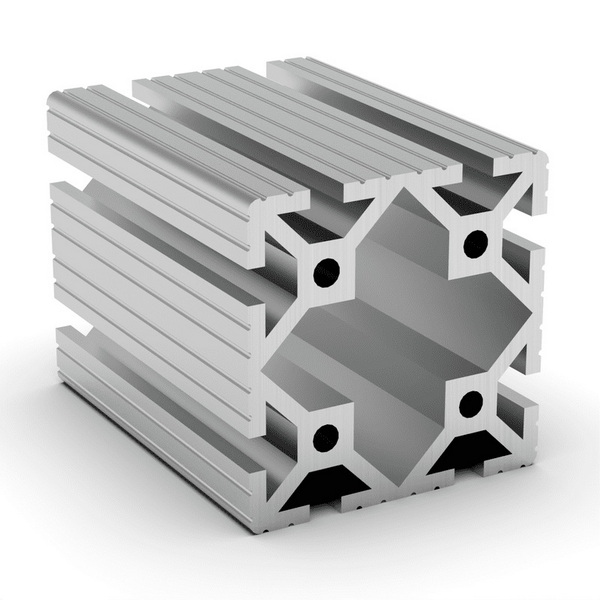

The term "4060" refers to the dimensions of the aluminum profile, specifically 40mm by 60mm. This size makes it ideal for a variety of applications, from structural frameworks to intricate designs. The extrusion process allows for the creation of complex shapes that can be tailored to specific needs, making it a valuable material in many sectors.

Benefits of 4060 Aluminum Extrusion

1. Lightweight and Strong: Aluminum is known for its high strength-to-weight ratio. The 4060 profile is robust enough to support significant loads while remaining lightweight, making it easier to handle and install.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer that helps resist corrosion. This property is particularly beneficial in environments where moisture and chemicals are present.

3. Versatility: The 4060 aluminum extrusion can be used in various applications, from industrial machinery to consumer products. Its adaptability makes it a go-to choice for engineers and designers.

4. Ease of Assembly: The T-slot design of the 4060 profile allows for easy assembly and disassembly. This feature is particularly useful in modular construction and equipment design.

5. Aesthetic Appeal: Aluminum can be finished in various ways, including anodizing and powder coating, allowing for a range of aesthetic options that can enhance the visual appeal of a project.

Applications of 4060 Aluminum Extrusion

Industrial Frameworks

One of the most common applications of 4060 aluminum extrusion is in the construction of industrial frameworks. These frameworks can support machinery, workstations, and other equipment. The strength and lightweight nature of aluminum make it an ideal choice for creating robust structures that can withstand heavy loads.

Automation and Robotics

In the field of automation, 4060 aluminum extrusion is frequently used to build frames for robotic systems. The modular nature of the T-slot design allows for easy customization and reconfiguration, which is essential in dynamic manufacturing environments. Robots can be mounted on these frames, providing stability and support for various tasks.

Workstations and Benches

Many industries utilize 4060 aluminum extrusion to create workstations and benches. The ability to customize the height, width, and layout of these workspaces makes aluminum extrusions a popular choice in manufacturing, laboratories, and assembly lines. The lightweight nature of aluminum also allows for easy mobility and adjustments.

Display and Retail Fixtures

In retail environments, 4060 aluminum extrusion is often used to create display fixtures. The sleek design and customizable nature of the profiles allow retailers to create attractive displays that can be easily modified to showcase different products. This flexibility is crucial in a fast-paced retail environment where product lines frequently change.

Transportation and Automotive

The automotive industry also benefits from the use of 4060 aluminum extrusion. It is used in the construction of vehicle frames, components, and even in the assembly of production lines. The lightweight nature of aluminum helps improve fuel efficiency in vehicles, making it a preferred material for modern automotive design.

Furniture Design

In contemporary furniture design, 4060 aluminum extrusion is increasingly popular. Designers appreciate the modern aesthetic and the ability to create lightweight yet sturdy furniture pieces. From office desks to shelving units, aluminum extrusions provide a sleek and functional solution.

Custom Machinery

Many manufacturers use 4060 aluminum extrusion to build custom machinery. The ability to create specific shapes and sizes allows for the design of machines tailored to unique production processes. This customization can lead to increased efficiency and productivity in manufacturing operations.

Greenhouses and Agricultural Structures

In agriculture, 4060 aluminum extrusion is used to construct greenhouses and other agricultural structures. The corrosion resistance of aluminum makes it suitable for outdoor environments, while its lightweight nature allows for easy installation and maintenance.

Signage and Displays

Aluminum extrusions are also used in the creation of signage and display systems. The durability and aesthetic appeal of aluminum make it an excellent choice for both indoor and outdoor signage. The 4060 profile can be used to create frames for signs that are both functional and visually appealing.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, 4060 aluminum extrusion is used to create ductwork and structural supports. The lightweight and corrosion-resistant properties of aluminum make it ideal for these applications, ensuring longevity and efficiency in HVAC systems.

Conclusion

The versatility of 4060 aluminum extrusion makes it an ideal choice for a wide range of applications across various industries. Its lightweight yet strong properties, combined with ease of assembly and aesthetic appeal, allow for innovative designs and efficient manufacturing processes. Whether in industrial frameworks, automation, furniture design, or agricultural structures, 4060 aluminum extrusion continues to be a preferred material for engineers and designers alike.

Frequently Asked Questions

1. What is the weight capacity of 4060 aluminum extrusion?

The weight capacity of 4060 aluminum extrusion depends on the specific design and application. Generally, it can support significant loads, making it suitable for various structural applications.

2. Can 4060 aluminum extrusion be used outdoors?

Yes, 4060 aluminum extrusion is corrosion-resistant, making it suitable for outdoor applications such as greenhouses and signage.

3. How is 4060 aluminum extrusion assembled?

4060 aluminum extrusion features a T-slot design that allows for easy assembly using brackets, fasteners, and connectors.

4. What finishes are available for 4060 aluminum extrusion?

4060 aluminum extrusion can be finished in various ways, including anodizing, powder coating, and natural finishes, allowing for aesthetic customization.

5. Is 4060 aluminum extrusion recyclable?

Yes, aluminum is highly recyclable, and 4060 aluminum extrusion can be recycled without losing its properties, making it an environmentally friendly choice.