Content Menu

● Understanding 30150 Aluminum Extrusion

>> Key Features of 30150 Aluminum Extrusion

● Applications of 30150 Aluminum Extrusion

>> Industrial Machinery

>> Workstations and Workbenches

>> Automation and Robotics

>> Architectural Applications

>> Transportation

>> Furniture Design

>> Display and Exhibition Stands

>> Custom Fabrication

>> Medical Equipment

>> Renewable Energy Systems

● Conclusion

● Frequently Asked Questions

>> 1. What is the weight capacity of 30150 aluminum extrusion?

>> 2. Can 30150 aluminum extrusion be used outdoors?

>> 3. How is 30150 aluminum extrusion assembled?

>> 4. Is 30150 aluminum extrusion customizable?

>> 5. What industries commonly use 30150 aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various profiles available, the 30150 aluminum extrusion stands out due to its versatility and strength. This article explores the applications best suited for 30150 aluminum extrusion, highlighting its benefits, features, and the industries that utilize it.

Understanding 30150 Aluminum Extrusion

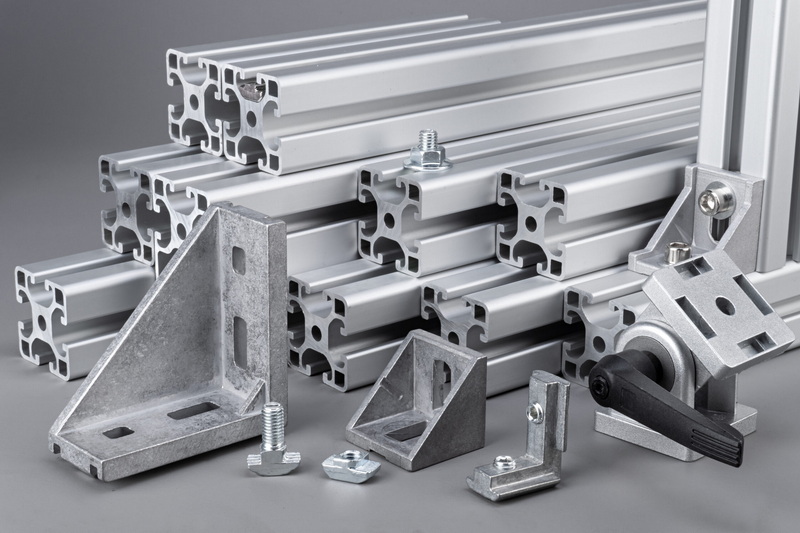

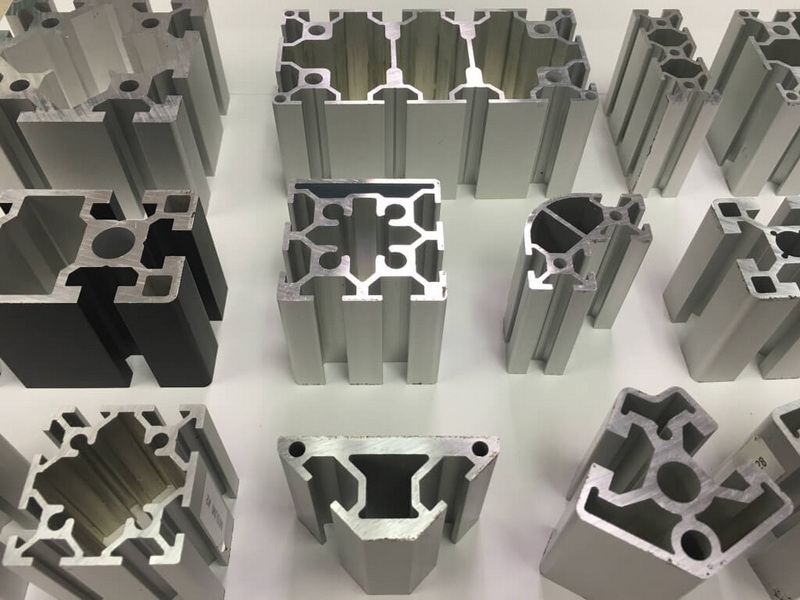

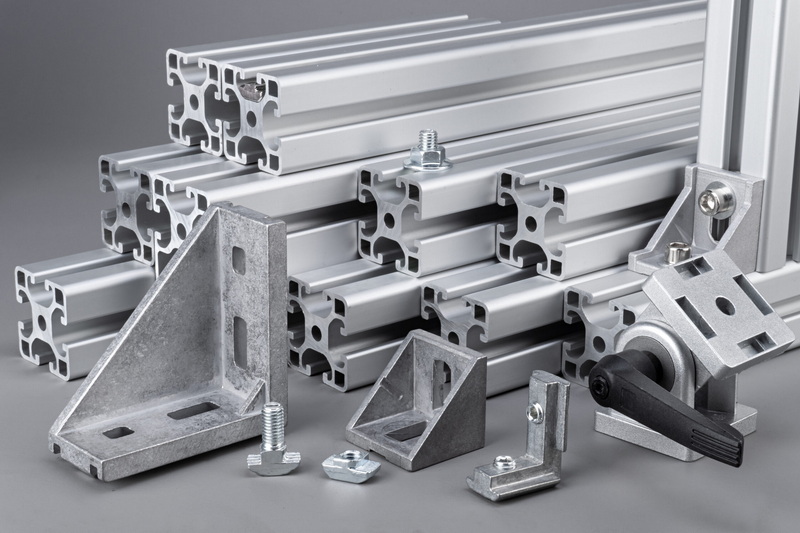

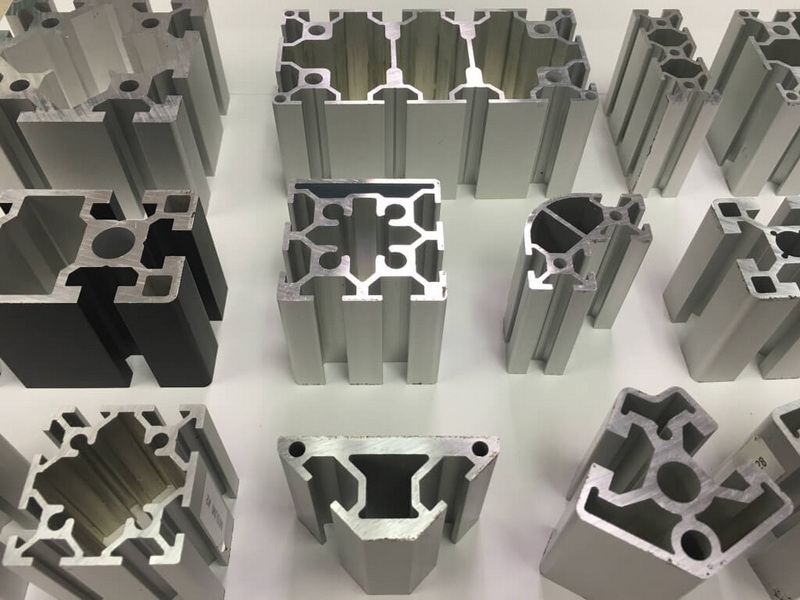

The 30150 aluminum extrusion profile measures 30mm by 150mm, making it one of the larger profiles in the 30 series. Its robust design allows it to support significant loads, making it ideal for various structural applications. The profile features multiple slots, which facilitate easy assembly and integration with other components, enhancing its adaptability in different settings.

Key Features of 30150 Aluminum Extrusion

1. High Strength-to-Weight Ratio: Aluminum is known for its lightweight properties, and the 30150 profile is no exception. This characteristic allows for easy handling and installation while maintaining structural integrity.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This feature is particularly beneficial in outdoor applications or environments with high humidity.

3. Versatility: The 30150 profile can be used in various applications, from industrial machinery to consumer products. Its adaptability makes it a popular choice among engineers and designers.

4. Ease of Assembly: The T-slot design of the 30150 extrusion allows for quick and easy assembly using standard fasteners. This feature reduces the time and labor required for construction.

5. Customizability: Manufacturers can produce 30150 aluminum extrusions in various lengths and finishes, allowing for customization to meet specific project requirements.

Applications of 30150 Aluminum Extrusion

Industrial Machinery

One of the primary applications of 30150 aluminum extrusion is in the construction of industrial machinery. Its strength and durability make it suitable for frames, supports, and enclosures. The profile can be used to create custom machinery that meets specific operational needs, enhancing productivity and efficiency. For instance, manufacturers can design machines that require specific dimensions and load capacities, ensuring optimal performance in various industrial settings.

Workstations and Workbenches

The 30150 profile is widely used in the design of workstations and workbenches. Its ability to support heavy loads makes it ideal for creating sturdy work surfaces. Additionally, the T-slot design allows for the easy addition of accessories such as shelves, tool holders, and lighting, making it a versatile choice for various work environments. This adaptability is particularly beneficial in manufacturing and assembly lines, where workstations need to be frequently reconfigured to accommodate different tasks.

Automation and Robotics

In the field of automation and robotics, the 30150 aluminum extrusion is often used to build frames and structures for robotic systems. Its lightweight nature allows for the creation of agile robots that can perform tasks efficiently. The profile's modular design enables easy modifications and upgrades, making it a favorite among engineers in the robotics industry. For example, robotic arms and automated guided vehicles (AGVs) can be constructed using 30150 profiles, allowing for quick assembly and reconfiguration as technology evolves.

Architectural Applications

The aesthetic appeal of aluminum makes the 30150 extrusion suitable for architectural applications. It can be used in the construction of facades, window frames, and other structural elements. The corrosion resistance of aluminum ensures that these components maintain their appearance and functionality over time, even in harsh weather conditions. Architects and designers appreciate the ability to create visually striking structures while benefiting from the durability and low maintenance of aluminum.

Transportation

The transportation industry also benefits from the use of 30150 aluminum extrusion. It can be used in the construction of vehicle frames, trailers, and other components where weight reduction is crucial. The strength of aluminum allows for the creation of lightweight yet durable structures that enhance fuel efficiency and performance. For instance, manufacturers of trucks and trailers often use aluminum extrusions to reduce overall vehicle weight, leading to improved fuel economy and payload capacity.

Furniture Design

The versatility of the 30150 aluminum extrusion extends to furniture design. Designers can create modern, minimalist furniture pieces that are both functional and aesthetically pleasing. The ability to customize lengths and finishes allows for unique designs that cater to various tastes and preferences. From office furniture to home decor, the 30150 profile can be used to create stylish and durable pieces that stand the test of time.

Display and Exhibition Stands

In the retail and exhibition sectors, the 30150 profile is often used to construct display stands and exhibition booths. Its lightweight nature makes it easy to transport and set up, while its strength ensures that it can support various display items. The modular design allows for quick reconfiguration, making it ideal for changing displays. Retailers and exhibitors appreciate the flexibility that aluminum extrusions provide, enabling them to adapt their displays to different products and marketing strategies.

Custom Fabrication

Many manufacturers utilize 30150 aluminum extrusion for custom fabrication projects. The ability to create unique profiles and components tailored to specific needs makes it a valuable resource in various industries. Whether for prototyping or large-scale production, the 30150 profile can be adapted to meet diverse requirements. This customizability is particularly important in industries where specific dimensions and performance characteristics are critical.

Medical Equipment

In the medical field, the 30150 aluminum extrusion is used to construct equipment and devices that require precision and reliability. Its lightweight and corrosion-resistant properties make it suitable for various medical applications, from hospital furniture to diagnostic equipment. Manufacturers of medical devices often choose aluminum extrusions for their ability to meet stringent regulatory standards while providing the necessary strength and durability.

Renewable Energy Systems

The renewable energy sector also benefits from the use of 30150 aluminum extrusion. It can be used in the construction of solar panel frames, wind turbine structures, and other components that require durability and resistance to environmental factors. The lightweight nature of aluminum helps improve the efficiency of these systems. For example, solar panel mounting systems made from 30150 profiles can be easily installed and adjusted, maximizing energy capture while minimizing installation time.

Conclusion

The 30150 aluminum extrusion profile is a versatile and robust solution for a wide range of applications. Its strength, lightweight nature, and ease of assembly make it an ideal choice for industries such as manufacturing, construction, transportation, and more. As technology advances and the demand for custom solutions increases, the use of 30150 aluminum extrusion is likely to expand further, solidifying its place as a key material in modern engineering and design.

Frequently Asked Questions

1. What is the weight capacity of 30150 aluminum extrusion?

The weight capacity of 30150 aluminum extrusion depends on the specific design and application. However, it is generally capable of supporting significant loads due to its robust construction.

2. Can 30150 aluminum extrusion be used outdoors?

Yes, 30150 aluminum extrusion is resistant to corrosion, making it suitable for outdoor applications. It can withstand various environmental conditions without deteriorating.

3. How is 30150 aluminum extrusion assembled?

The T-slot design of the 30150 profile allows for easy assembly using standard fasteners. Components can be quickly connected and adjusted as needed.

4. Is 30150 aluminum extrusion customizable?

Yes, manufacturers can produce 30150 aluminum extrusions in various lengths and finishes, allowing for customization to meet specific project requirements.

5. What industries commonly use 30150 aluminum extrusion?

Industries such as manufacturing, construction, transportation, robotics, and medical equipment frequently utilize 30150 aluminum extrusion for various applications.