Content Menu

● Understanding 30 Series Aluminum Extrusion

>> What is 30 Series Aluminum Extrusion?

>> Key Characteristics

● Applications of 30 Series Aluminum Extrusion

>> 1. Construction and Architecture

>> 2. Automotive Industry

>> 3. Aerospace Applications

>> 4. Industrial Equipment

>> 5. Furniture and Fixtures

>> 6. Electronics and Technology

>> 7. Transportation and Logistics

● Benefits of Using 30 Series Aluminum Extrusion

>> 1. Cost-Effectiveness

>> 2. Sustainability

>> 3. Design Flexibility

>> 4. Strength and Durability

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between 30 Series and other aluminum extrusions?

>> 2. Can 30 Series aluminum extrusion be used outdoors?

>> 3. How is 30 Series aluminum extrusion fabricated?

>> 4. What are the environmental benefits of using aluminum extrusion?

>> 5. Is 30 Series aluminum extrusion suitable for high-temperature applications?

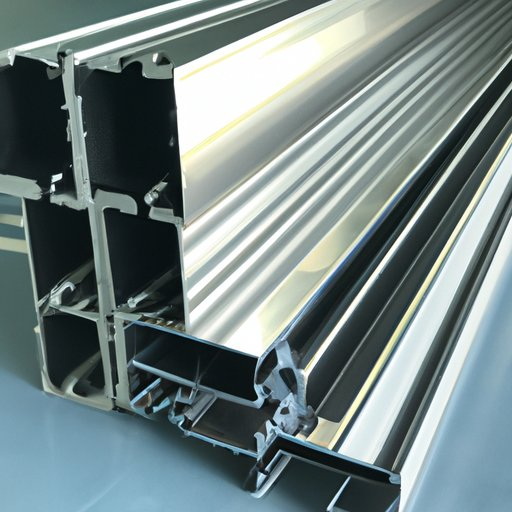

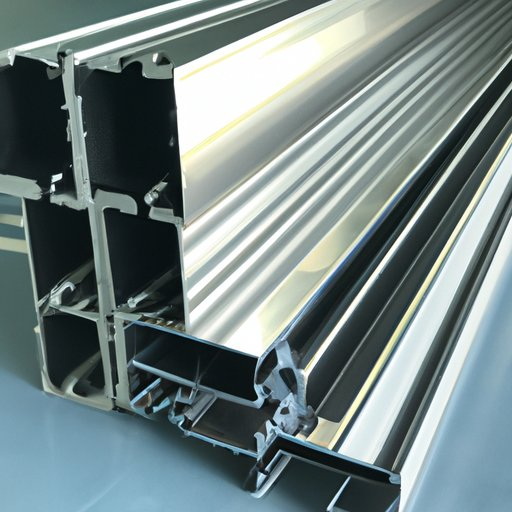

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The 30 Series aluminum extrusion, specifically, is known for its versatility, strength, and lightweight properties, making it an ideal choice for various applications across multiple industries. This article will explore the best applications suited for 30 Series aluminum extrusion, highlighting its benefits, characteristics, and real-world uses.

Understanding 30 Series Aluminum Extrusion

What is 30 Series Aluminum Extrusion?

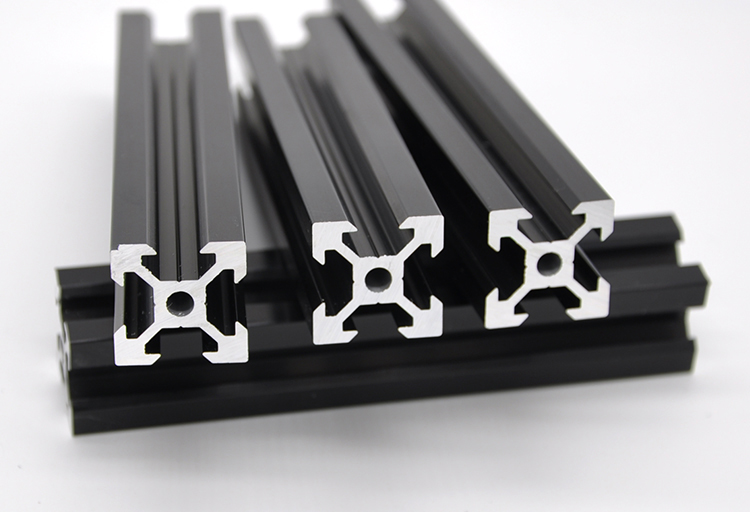

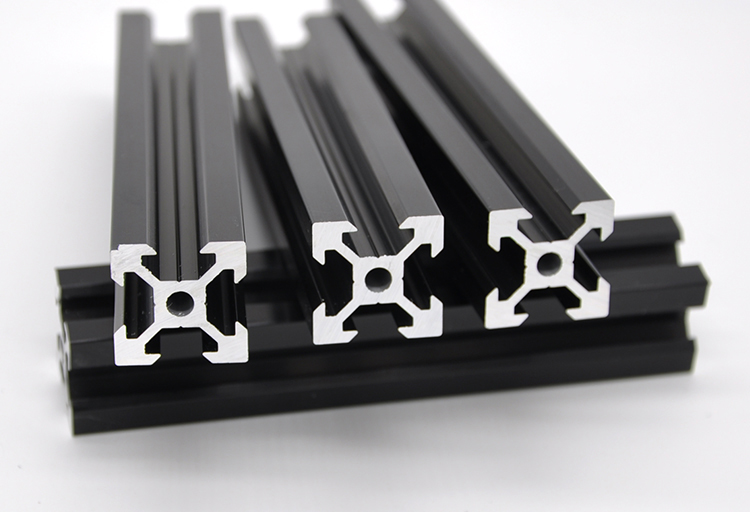

The 30 Series aluminum extrusion refers to a specific range of aluminum profiles that are typically used in structural applications. These profiles are made from aluminum alloys, primarily 6060 and 6061, which are known for their excellent mechanical properties and corrosion resistance. The 30 Series is characterized by its medium strength and is often used in applications where weight savings are crucial without compromising structural integrity.

Key Characteristics

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion.

- Versatility: The extrusion process allows for a wide variety of shapes and sizes, accommodating different design needs.

- Ease of Fabrication: 30 Series profiles can be easily cut, drilled, and assembled, making them suitable for custom applications.

Applications of 30 Series Aluminum Extrusion

1. Construction and Architecture

One of the most prominent applications of 30 Series aluminum extrusion is in the construction and architectural sectors. It is used for:

- Window Frames: The lightweight and durable nature of aluminum makes it an excellent choice for window frames, providing both aesthetic appeal and structural support. Aluminum frames can be designed to accommodate large panes of glass, enhancing natural light in buildings while maintaining energy efficiency.

- Curtain Walls: Aluminum extrusions are commonly used in curtain wall systems, allowing for large glass panels that enhance natural light while maintaining energy efficiency. The flexibility of aluminum allows architects to create innovative designs that are both functional and visually appealing.

- Structural Supports: In commercial buildings, 30 Series profiles can be used as structural supports, providing strength without adding excessive weight. This is particularly important in high-rise buildings where every pound counts.

2. Automotive Industry

The automotive industry has increasingly turned to aluminum extrusions to reduce vehicle weight and improve fuel efficiency. Applications include:

- Chassis Components: 30 Series aluminum profiles are used in the construction of vehicle chassis, providing strength while minimizing weight. This reduction in weight contributes to better fuel economy and improved handling.

- Interior Structures: Aluminum extrusions are also used in the interior of vehicles, such as seat frames and dashboard supports, contributing to overall vehicle performance. The use of aluminum helps manufacturers meet stringent safety standards while keeping the vehicle lightweight.

3. Aerospace Applications

In the aerospace sector, weight reduction is critical for improving fuel efficiency and performance. 30 Series aluminum extrusion is used for:

- Aircraft Frames: The lightweight and high-strength properties of aluminum make it ideal for aircraft frames and components. The aerospace industry relies on aluminum extrusions for their ability to withstand extreme conditions while maintaining structural integrity.

- Support Structures: Various support structures within aircraft, such as bulkheads and stringers, utilize aluminum extrusions for their strength-to-weight ratio. This allows for more efficient designs that can enhance the overall performance of the aircraft.

4. Industrial Equipment

30 Series aluminum extrusion is widely used in the manufacturing of industrial equipment due to its durability and ease of fabrication. Applications include:

- Machine Frames: Many industrial machines utilize aluminum extrusions for their frames, providing a robust structure that can withstand heavy use. The lightweight nature of aluminum also allows for easier mobility and installation of machinery.

- Conveyor Systems: Aluminum profiles are often used in conveyor systems, allowing for lightweight and efficient material handling solutions. The flexibility of aluminum extrusions enables the design of custom conveyor systems tailored to specific operational needs.

5. Furniture and Fixtures

The furniture industry has embraced aluminum extrusion for its modern aesthetic and functional properties. Applications include:

- Office Furniture: Aluminum frames are used in desks, chairs, and partitions, offering a sleek and contemporary look. The durability of aluminum ensures that office furniture can withstand daily use while maintaining its appearance.

- Display Fixtures: Retail environments often use aluminum extrusions for display fixtures, providing a durable and attractive way to showcase products. The versatility of aluminum allows for creative designs that can enhance the shopping experience.

6. Electronics and Technology

In the electronics sector, 30 Series aluminum extrusion is used for:

- Heat Sinks: Aluminum's excellent thermal conductivity makes it ideal for heat sinks in electronic devices, helping to dissipate heat effectively. This is crucial for maintaining the performance and longevity of electronic components.

- Enclosures: Many electronic enclosures are made from aluminum extrusions, providing protection while maintaining a lightweight design. The use of aluminum helps manufacturers create products that are both functional and aesthetically pleasing.

7. Transportation and Logistics

The transportation industry benefits from the lightweight nature of aluminum extrusions, which can enhance efficiency. Applications include:

- Railway Components: Aluminum profiles are used in various railway components, including carriages and support structures. The lightweight nature of aluminum helps improve fuel efficiency in rail transport.

- Shipping Containers: Lightweight aluminum extrusions are increasingly used in shipping containers, reducing overall transport costs. The durability of aluminum also ensures that containers can withstand harsh shipping conditions.

Benefits of Using 30 Series Aluminum Extrusion

1. Cost-Effectiveness

While aluminum can be more expensive than other materials like steel, the long-term savings from reduced weight and improved fuel efficiency often outweigh initial costs. The ability to create complex shapes and designs can also lead to reduced manufacturing costs.

2. Sustainability

Aluminum is highly recyclable, making it an environmentally friendly choice. The use of aluminum extrusions can contribute to sustainable building practices and reduce the carbon footprint of various applications. Many manufacturers are now focusing on using recycled aluminum, further enhancing the sustainability of their products.

3. Design Flexibility

The extrusion process allows for complex shapes and designs, enabling engineers and designers to create innovative solutions tailored to specific needs. This flexibility is particularly beneficial in industries where customization is key to meeting client demands.

4. Strength and Durability

30 Series aluminum profiles offer excellent strength-to-weight ratios, making them suitable for demanding applications where durability is essential. The inherent properties of aluminum ensure that structures remain robust over time, even in challenging environments.

Conclusion

30 Series aluminum extrusion is a versatile and valuable material used across various industries, from construction and automotive to aerospace and electronics. Its lightweight, durable, and corrosion-resistant properties make it an ideal choice for applications requiring strength without added weight. As industries continue to seek sustainable and efficient solutions, the demand for aluminum extrusions is likely to grow, further solidifying their role in modern manufacturing and design.

Frequently Asked Questions

1. What is the difference between 30 Series and other aluminum extrusions?

The 30 Series is specifically designed for medium-strength applications, while other series may offer higher strength or different properties suited for specific uses.

2. Can 30 Series aluminum extrusion be used outdoors?

Yes, 30 Series aluminum is corrosion-resistant and can be used in outdoor applications, although proper finishing may enhance its durability.

3. How is 30 Series aluminum extrusion fabricated?

It can be easily cut, drilled, and assembled, allowing for customization in various applications.

4. What are the environmental benefits of using aluminum extrusion?

Aluminum is highly recyclable, reducing waste and energy consumption in manufacturing processes.

5. Is 30 Series aluminum extrusion suitable for high-temperature applications?

While aluminum has good thermal properties, it may not be suitable for extremely high-temperature applications without proper design considerations.