Content Menu

● Understanding Aluminum Extrusions

● Key Properties of 2-Inch Aluminum Extrusions

● Applications of 2-Inch Aluminum Extrusions

>> 1. Construction and Architecture

>> 2. Automotive Industry

>> 3. Aerospace Applications

>> 4. Furniture Manufacturing

>> 5. Electronics and Electrical Enclosures

>> 6. Marine Applications

>> 7. Signage and Display Systems

● Advantages of Using 2-Inch Aluminum Extrusions

● Conclusion

● Related Questions

>> 1. What are the typical costs associated with 2-inch aluminum extrusions?

>> 2. How do different alloys of aluminum affect the properties of 2-inch extrusions?

>> 3. What are the environmental impacts of producing 2-inch aluminum extrusions?

>> 4. Can 2-inch aluminum extrusions be used in 3D printing applications?

>> 5. What maintenance is required for 2-inch aluminum extrusions?

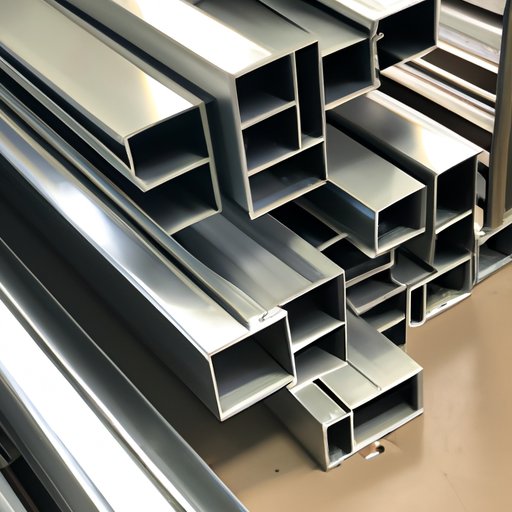

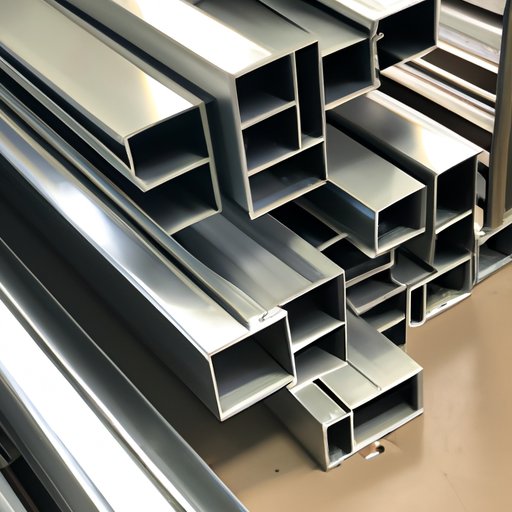

Aluminum extrusions are a versatile and widely used material in various industries due to their lightweight, strength, and corrosion resistance. Among the different sizes available, 2-inch aluminum extrusions stand out for their adaptability and functionality. This article explores the applications best suited for 2-inch aluminum extrusions, highlighting their benefits and providing insights into their use across various sectors.

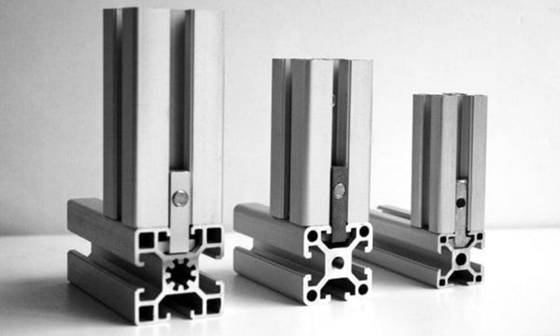

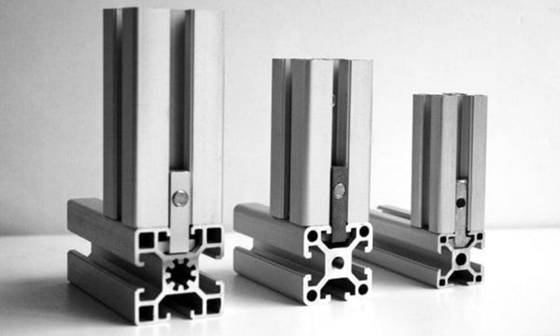

Understanding Aluminum Extrusions

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. The process begins with heating aluminum billets until they become malleable, followed by forcing the heated aluminum through a die to create the desired shape. This method allows for the production of complex shapes with precise dimensions, making aluminum extrusions ideal for a wide range of applications.

Key Properties of 2-Inch Aluminum Extrusions

2-inch aluminum extrusions possess several key properties that make them particularly suitable for various applications:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Strength: Despite its lightweight nature, aluminum has a high strength-to-weight ratio, providing durability and structural integrity.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for outdoor applications.

- Versatility: The extrusion process allows for a wide range of shapes and sizes, enabling customization for specific needs.

Applications of 2-Inch Aluminum Extrusions

1. Construction and Architecture

In the construction industry, 2-inch aluminum extrusions are commonly used for window frames, door frames, and curtain walls. Their lightweight nature reduces the overall weight of structures, while their strength ensures stability. Additionally, aluminum's resistance to corrosion makes it an ideal choice for buildings exposed to harsh weather conditions.

2. Automotive Industry

The automotive sector utilizes 2-inch aluminum extrusions for various components, including chassis, structural supports, and trim pieces. The lightweight properties of aluminum contribute to improved fuel efficiency in vehicles, making it a preferred material for manufacturers aiming to reduce emissions and enhance performance.

3. Aerospace Applications

In aerospace, weight reduction is critical for performance and fuel efficiency. 2-inch aluminum extrusions are used in aircraft frames, wing structures, and interior components. The high strength-to-weight ratio of aluminum allows for the design of lightweight yet robust structures that can withstand the rigors of flight.

4. Furniture Manufacturing

Aluminum extrusions are increasingly popular in furniture design, particularly for modern and minimalist styles. 2-inch extrusions are used in the construction of tables, chairs, and shelving units. Their sleek appearance and durability make them an attractive choice for both residential and commercial furniture.

5. Electronics and Electrical Enclosures

In the electronics industry, 2-inch aluminum extrusions are often used to create enclosures for electronic devices. The material's excellent thermal conductivity helps dissipate heat, protecting sensitive components. Additionally, aluminum's non-magnetic properties make it suitable for various electronic applications.

6. Marine Applications

The marine industry benefits from the corrosion resistance of aluminum, making 2-inch extrusions ideal for boat frames, railings, and other structural components. Aluminum's lightweight nature also contributes to improved performance and fuel efficiency in marine vessels.

7. Signage and Display Systems

2-inch aluminum extrusions are widely used in the signage industry for creating frames and supports for signs and displays. Their durability and ability to withstand outdoor conditions make them a reliable choice for both permanent and temporary signage solutions.

Advantages of Using 2-Inch Aluminum Extrusions

The use of 2-inch aluminum extrusions offers several advantages across various applications:

- Cost-Effectiveness: While the initial cost of aluminum may be higher than some materials, its durability and low maintenance requirements lead to long-term savings.

- Sustainability: Aluminum is 100% recyclable, making it an environmentally friendly choice. The recycling process requires only a fraction of the energy needed to produce new aluminum, reducing the overall carbon footprint.

- Customization: The extrusion process allows for the creation of custom shapes and sizes, enabling manufacturers to meet specific design requirements.

Conclusion

2-inch aluminum extrusions are a versatile and valuable material across multiple industries. Their lightweight, strength, and corrosion resistance make them suitable for applications in construction, automotive, aerospace, furniture, electronics, marine, and signage. As industries continue to seek sustainable and efficient materials, the demand for aluminum extrusions is likely to grow, further solidifying their place in modern manufacturing.

Related Questions

1. What are the typical costs associated with 2-inch aluminum extrusions?

The cost of 2-inch aluminum extrusions can vary based on factors such as the alloy used, the complexity of the design, and the quantity ordered. Generally, aluminum extrusions are competitively priced compared to other materials, especially when considering their durability and low maintenance costs.

2. How do different alloys of aluminum affect the properties of 2-inch extrusions?

Different aluminum alloys offer varying properties, such as strength, corrosion resistance, and workability. For example, 6061 aluminum is known for its good mechanical properties and weldability, making it suitable for structural applications, while 6063 is often used for architectural applications due to its excellent finish and extrudability.

3. What are the environmental impacts of producing 2-inch aluminum extrusions?

The production of aluminum extrusions has environmental impacts, primarily related to energy consumption and greenhouse gas emissions. However, aluminum is highly recyclable, and recycling aluminum uses significantly less energy than producing new aluminum from ore, making it a more sustainable option in the long run.

4. Can 2-inch aluminum extrusions be used in 3D printing applications?

Yes, 2-inch aluminum extrusions can be used in 3D printing applications, particularly in the construction of 3D printer frames and supports. Their lightweight and sturdy nature makes them ideal for creating stable structures that can support the weight of the printer and its components.

5. What maintenance is required for 2-inch aluminum extrusions?

Aluminum extrusions require minimal maintenance due to their corrosion resistance. Regular cleaning with mild soap and water is usually sufficient to maintain their appearance. In harsh environments, additional protective coatings may be applied to enhance durability.