Content Menu

● Understanding 1545 Aluminum Extrusion

● Key Properties of 1545 Aluminum

● Applications of 1545 Aluminum Extrusion

>> 1. Aerospace Industry

>> 2. Automotive Industry

>> 3. Construction and Architecture

>> 4. Electrical and Electronics

>> 5. Marine Applications

>> 6. Industrial Equipment

>> 7. Furniture and Fixtures

● Advantages of Using 1545 Aluminum Extrusion

● Conclusion

● Related Questions

>> 1. What are the benefits of using aluminum extrusion over other manufacturing processes?

>> 2. How does the corrosion resistance of 1545 aluminum compare to other materials?

>> 3. Can 1545 aluminum extrusion be used in high-temperature applications?

>> 4. What is the typical lifespan of products made from 1545 aluminum extrusion?

>> 5. Is 1545 aluminum extrusion recyclable?

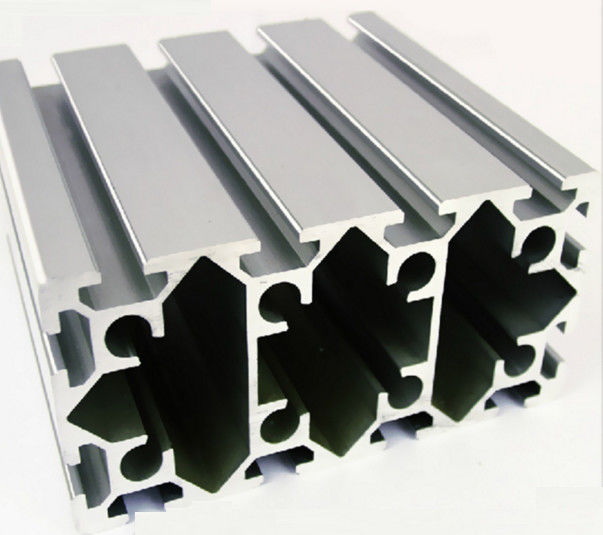

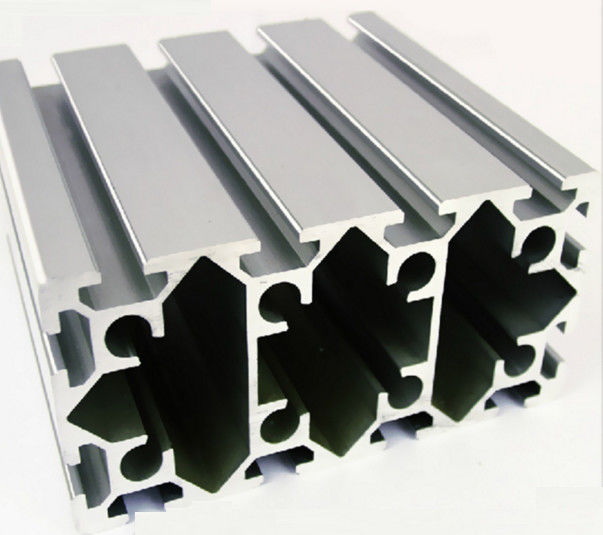

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. Among the various aluminum alloys available, 1545 aluminum extrusion is particularly notable for its unique properties and versatility. This article explores the applications best suited for 1545 aluminum extrusion, highlighting its advantages, characteristics, and the industries that benefit from its use.

Understanding 1545 Aluminum Extrusion

1545 aluminum is a heat-treatable alloy primarily composed of aluminum, copper, and small amounts of other elements. This alloy is known for its excellent mechanical properties, including high strength-to-weight ratio, good corrosion resistance, and excellent machinability. The extrusion process allows for the creation of complex shapes and profiles, making it ideal for various applications.

Key Properties of 1545 Aluminum

Before delving into its applications, it is essential to understand the key properties that make 1545 aluminum extrusion a preferred choice in many industries:

- Strength: 1545 aluminum exhibits high tensile strength, making it suitable for structural applications where load-bearing capacity is crucial.

- Lightweight: Aluminum is significantly lighter than steel, which is advantageous in applications where weight reduction is essential, such as in aerospace and automotive industries.

- Corrosion Resistance: The alloy's natural oxide layer provides excellent resistance to corrosion, making it suitable for outdoor and marine applications.

- Machinability: 1545 aluminum can be easily machined, allowing for precise fabrication of components.

Applications of 1545 Aluminum Extrusion

1. Aerospace Industry

The aerospace industry is one of the primary sectors that benefit from 1545 aluminum extrusion. The lightweight nature of aluminum is critical in aircraft design, where reducing weight can lead to improved fuel efficiency and performance. Components such as wing structures, fuselage frames, and support brackets are often made from 1545 aluminum due to its strength and durability.

2. Automotive Industry

In the automotive sector, 1545 aluminum extrusion is used to manufacture various components, including chassis, frames, and body panels. The alloy's lightweight properties contribute to overall vehicle efficiency, enhancing fuel economy and reducing emissions. Additionally, the corrosion resistance of 1545 aluminum ensures longevity and reliability in automotive applications.

3. Construction and Architecture

The construction industry utilizes 1545 aluminum extrusion for structural applications, such as window frames, doors, and curtain walls. The alloy's strength allows for the creation of slender profiles that can support significant loads while maintaining aesthetic appeal. Furthermore, the corrosion resistance of aluminum makes it an ideal choice for outdoor applications, ensuring durability in various weather conditions.

4. Electrical and Electronics

1545 aluminum extrusion is also prevalent in the electrical and electronics industry. It is used to create heat sinks, enclosures, and structural components for electronic devices. The excellent thermal conductivity of aluminum helps dissipate heat effectively, ensuring the longevity and performance of electronic components.

5. Marine Applications

In marine environments, 1545 aluminum extrusion is favored for its resistance to corrosion and lightweight properties. It is commonly used in the construction of boat frames, masts, and other structural components. The ability to withstand harsh marine conditions makes it a reliable choice for boat manufacturers.

6. Industrial Equipment

Industrial equipment manufacturers often use 1545 aluminum extrusion for creating frames, supports, and housings for machinery. The strength and lightweight nature of the alloy allow for the design of robust yet portable equipment, enhancing operational efficiency in various industrial applications.

7. Furniture and Fixtures

The furniture industry has also embraced 1545 aluminum extrusion for creating modern and stylish designs. Aluminum's versatility allows for innovative furniture designs that are both functional and aesthetically pleasing. From office furniture to outdoor seating, 1545 aluminum provides durability and style.

Advantages of Using 1545 Aluminum Extrusion

The use of 1545 aluminum extrusion offers several advantages across various applications:

- Cost-Effectiveness: While the initial cost of aluminum may be higher than some materials, its lightweight nature can lead to significant savings in transportation and installation costs.

- Sustainability: Aluminum is highly recyclable, making it an environmentally friendly choice. The use of recycled aluminum in extrusion processes reduces energy consumption and environmental impact.

- Design Flexibility: The extrusion process allows for the creation of complex shapes and profiles, enabling designers to innovate and create unique products.

Conclusion

1545 aluminum extrusion is a versatile and valuable material used across multiple industries. Its unique properties, including strength, lightweight, and corrosion resistance, make it ideal for applications in aerospace, automotive, construction, electronics, marine, industrial equipment, and furniture. As industries continue to seek lightweight and durable materials, the demand for 1545 aluminum extrusion is likely to grow, further solidifying its place in modern manufacturing.

Related Questions

1. What are the benefits of using aluminum extrusion over other manufacturing processes?

Aluminum extrusion offers several benefits, including the ability to create complex shapes, reduced waste, and improved material properties. It also allows for faster production times and lower costs in many applications.

2. How does the corrosion resistance of 1545 aluminum compare to other materials?

1545 aluminum has excellent corrosion resistance due to its natural oxide layer, making it superior to many steel alloys in environments prone to moisture and corrosion.

3. Can 1545 aluminum extrusion be used in high-temperature applications?

While 1545 aluminum has good thermal properties, it is not recommended for high-temperature applications exceeding its melting point. For such applications, other materials or aluminum alloys with higher temperature resistance may be more suitable.

4. What is the typical lifespan of products made from 1545 aluminum extrusion?

The lifespan of products made from 1545 aluminum extrusion can vary based on environmental conditions and usage. However, with proper care and maintenance, aluminum products can last for decades.

5. Is 1545 aluminum extrusion recyclable?

Yes, 1545 aluminum extrusion is highly recyclable. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, making it an environmentally friendly choice.