Content Menu

● Understanding 40mm x 40mm Aluminum Extrusions

>> Key Specifications

● Essential Accessories for 40mm x 40mm Aluminum Extrusions

>> 1. T-Nuts and Bolts

>> 2. Corner Brackets

>> 3. End Caps

>> 4. Connectors

>> 5. Wheels and Casters

● Additional Components to Consider

>> 6. Sliding Doors and Panels

>> 7. Shelving Brackets

>> 8. Cable Management Accessories

>> 9. Lighting Fixtures

>> 10. Vibration Dampeners

● Visual Examples of Accessories in Use

● Practical Applications of 40mm x 40mm Aluminum Extrusions

>> 1. Workstations

>> 2. Robotics Frames

>> 3. Display Stands

>> 4. Enclosures

● Conclusion

● Related Questions

>> 1. What is the weight capacity of a 40mm x 40mm aluminum extrusion?

>> 2. Can I cut 40mm x 40mm aluminum extrusions to custom lengths?

>> 3. Are there specific tools required for assembling aluminum extrusions?

>> 4. How do I ensure my assembly is square?

>> 5. What types of finishes are available for aluminum extrusions?

Aluminum extrusions, particularly the 40mm x 40mm profiles, are widely recognized for their versatility and strength in various applications. This article delves into the accessories and components that complement these extrusions, enhancing their functionality and enabling users to create robust structures efficiently.

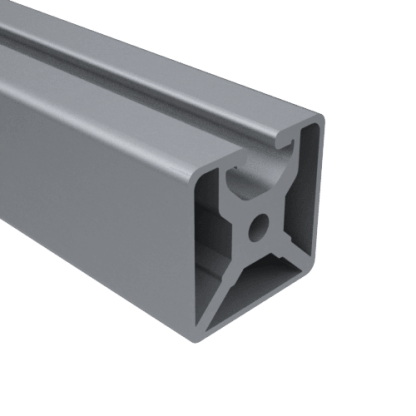

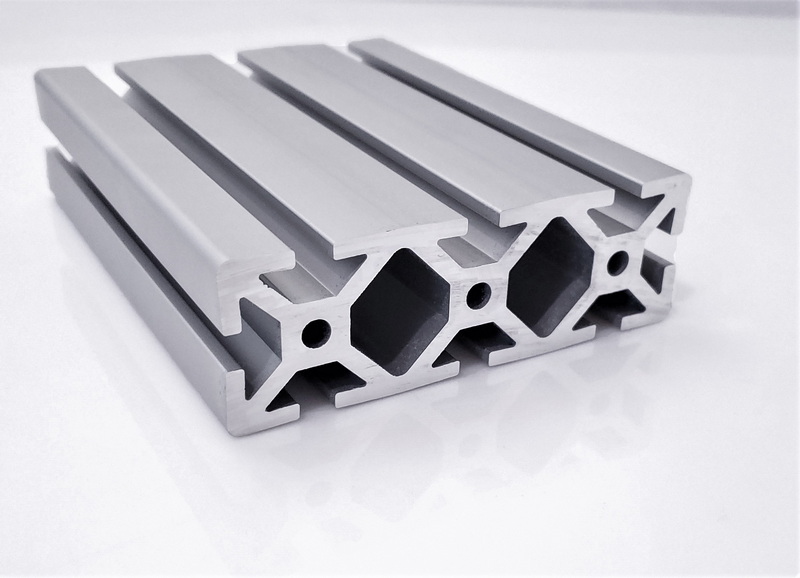

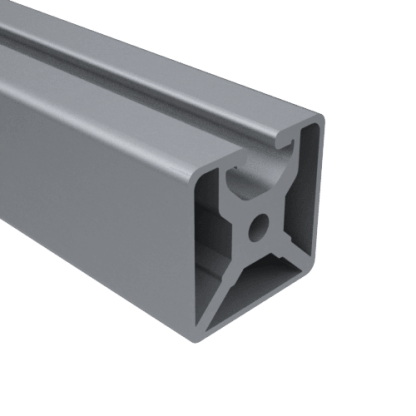

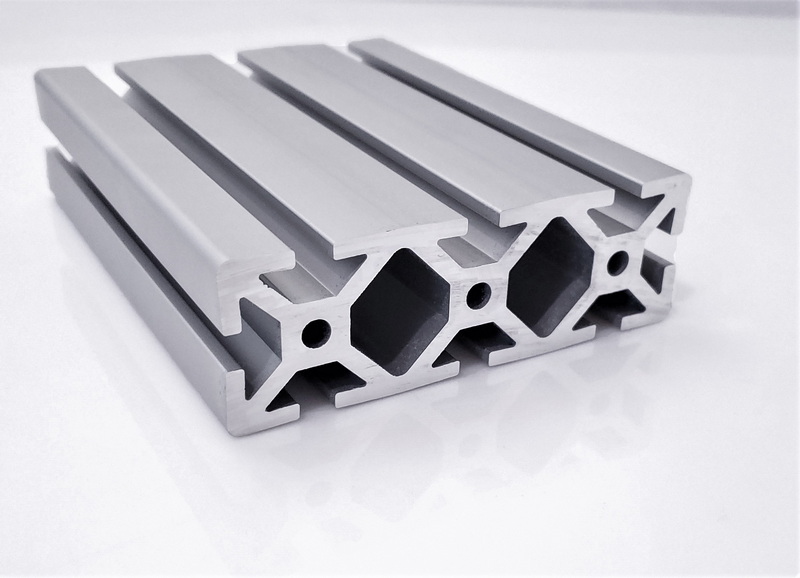

Understanding 40mm x 40mm Aluminum Extrusions

The 40mm x 40mm aluminum extrusion is part of the T-slot framing system, which is characterized by its four open T-slots on each face. This design allows for easy assembly and modification of structures, making it a preferred choice in industries ranging from manufacturing to robotics.

Key Specifications

- Slot Width: 8.2 mm

- Weight: Approximately 1.75 kg/m

- Material: Typically made from high-strength aluminum alloy

- Applications: Used in machine frames, workstations, enclosures, and more

Essential Accessories for 40mm x 40mm Aluminum Extrusions

To maximize the potential of 40mm x 40mm aluminum extrusions, various accessories can be integrated. Here are some of the most effective components:

1. T-Nuts and Bolts

T-nuts are essential for securing components to the extrusion profile. The M8 T-nut is a popular choice for the 40mm x 40mm aluminum extrusion, allowing for a secure connection without compromising the structural integrity.

- M8 T-Bolt: Used in conjunction with T-nuts to create strong joints.

- Flange Nuts: Provide a larger surface area to distribute load and prevent loosening.

T-nuts come in various designs, such as drop-in T-nuts, which allow for easy installation without removing the profile from its mounting position. This feature is particularly advantageous when modifications or additions are necessary after initial assembly.

2. Corner Brackets

Corner brackets are used to create right angles between two extrusion pieces. They enhance stability and rigidity in structures.

- L-Brackets: Ideal for connecting two profiles at a right angle.

- Angle Brackets: Useful for reinforcing joints in larger assemblies.

Using corner brackets not only provides structural integrity but also simplifies assembly processes, allowing for quicker setups of complex frameworks like workstations or display units.

3. End Caps

End caps are used to cover the open ends of aluminum extrusions, providing a finished look while preventing dirt and debris from entering the slots.

- Plastic End Caps: Lightweight and easy to install.

- Metal End Caps: Offer additional durability and protection.

End caps contribute to safety by eliminating sharp edges, making them ideal for environments where personnel may come into contact with the structure frequently.

4. Connectors

Connectors allow multiple profiles to be joined together seamlessly, creating complex structures.

- Joining Plates: Facilitate connections between two or more profiles.

- Hinges: Enable movable connections for doors or panels within a frame.

Connectors come in various types, including flat plates for simple connections and specialized connectors that allow for angled joints, expanding design possibilities significantly.

5. Wheels and Casters

For mobile applications, adding wheels or casters to your structure can enhance mobility.

- Swivel Casters: Allow for easy maneuverability.

- Fixed Wheels: Provide stability when the structure needs to remain stationary.

Choosing the right wheels is crucial; load-bearing capacity should match or exceed that of the entire assembly to ensure safety and functionality during movement.

Additional Components to Consider

In addition to the primary accessories listed above, several other components can further enhance the functionality of your 40mm x 40mm aluminum extrusion projects:

6. Sliding Doors and Panels

Sliding doors made from aluminum extrusions can be integrated into frames for enclosures or cabinets, providing access while maintaining a sleek appearance. These doors can be designed using lightweight panels that glide smoothly along tracks integrated into the extrusion framework.

7. Shelving Brackets

For creating shelving systems using aluminum extrusions, specialized brackets designed to fit within the T-slots can be used. These brackets can support various shelf materials, including wood or metal sheets, allowing customization based on load requirements.

8. Cable Management Accessories

To keep electrical wiring organized within your structures, cable management clips can be attached along the profiles. These clips help maintain a tidy appearance while preventing tangling or damage to wires during operation.

9. Lighting Fixtures

Integrating LED lighting into your aluminum extrusion projects can enhance visibility and aesthetics. Specialized mounting brackets allow you to attach lights directly onto the profiles without compromising structural integrity.

10. Vibration Dampeners

For applications involving machinery or equipment that generates vibrations, vibration dampeners can be attached to minimize noise and wear on connected components. These dampeners are critical in maintaining performance over time in industrial settings.

Visual Examples of Accessories in Use

To better illustrate how these accessories function with 40mm x 40mm aluminum extrusions, consider these images:

- T-Nuts and Bolts

- Corner Brackets

- End Caps

- Connectors

- Wheels and Casters

Practical Applications of 40mm x 40mm Aluminum Extrusions

Understanding how these components work together opens up numerous practical applications:

1. Workstations

In industrial settings, custom workstations can be built using 40mm x 40mm aluminum extrusions, equipped with shelving brackets for tools and cable management systems for electrical devices.

2. Robotics Frames

Robotics often requires lightweight yet sturdy frames that can withstand dynamic loads; thus, using these extrusions allows engineers to create adaptable designs that can evolve as projects progress.

3. Display Stands

Retail environments benefit from modular display stands constructed from aluminum extrusions; these stands can be reconfigured easily based on product layouts or seasonal displays.

4. Enclosures

Custom enclosures for machinery or electronics provide protection while allowing airflow; integrating sliding doors enhances accessibility without compromising security.

Conclusion

The versatility of 40mm x 40mm aluminum extrusions makes them an excellent choice for various construction projects. By integrating compatible accessories such as T-nuts, corner brackets, end caps, connectors, wheels, and more, users can create robust and flexible structures tailored to their specific needs. Whether you're building a workstation, a machine frame, or an enclosure, understanding these components will enhance your design's efficiency and effectiveness.

Related Questions

1. What is the weight capacity of a 40mm x 40mm aluminum extrusion?

The weight capacity largely depends on the specific application and configuration but generally ranges from 100 kg to over 200 kg depending on support conditions.

2. Can I cut 40mm x 40mm aluminum extrusions to custom lengths?

Yes, these extrusions can be easily cut using standard cutting tools designed for aluminum materials.

3. Are there specific tools required for assembling aluminum extrusions?

Basic hand tools such as wrenches and screwdrivers are typically sufficient; however, specialized tools like a miter saw may be beneficial for cutting.

4. How do I ensure my assembly is square?

Using corner brackets during assembly helps maintain square joints; additionally, measuring diagonals can confirm squareness.

5. What types of finishes are available for aluminum extrusions?

Common finishes include anodizing (for corrosion resistance) and powder coating (for aesthetic appeal).