Content Menu

● Understanding Quenching Systems

>> What is a Quenching System?

>> Types of Quenching Systems

>> The Importance of Quenching Systems in Modern Manufacturing

● The South Korean Heat Treatment Industry

>> Key Drivers of Growth

● Top Quenching System Manufacturers And Suppliers in South Korea

>> SAMWOO FMC Co., Ltd.

>> Thermvac Inc.

>> Dongkuk Industries Co., Ltd.

>> SAC Co., Ltd.

>> Other Notable Suppliers

● Key Technologies and Innovations

>> Automation and Digital Control

>> Energy Efficiency and Sustainability

>> Customization and Flexibility

>> Advanced Quenching Media

● Applications of Quenching Systems

● Choosing the Right Quenching System Manufacturer or Supplier

● Trends Shaping the Future of Quenching Systems in South Korea

>> Digitalization and Smart Manufacturing

>> Environmental Regulations and Green Manufacturing

>> Global Partnerships and Export Growth

● Conclusion

● Frequently Asked Questions

>> 1. What are the main types of quenching systems offered by South Korean manufacturers?

>> 2. How do South Korean quenching systems ensure energy efficiency?

>> 3. Are South Korean quenching system suppliers experienced in exporting?

>> 4. What industries benefit most from South Korean quenching systems?

>> 5. How can I contact top quenching system manufacturers and suppliers in South Korea?

In today's global manufacturing landscape, the need for high-performance heat treatment solutions is more critical than ever. Quenching systems are at the heart of this demand, providing essential processes that enhance the mechanical properties of metals and alloys. These systems ensure that components used in industries like automotive, aerospace, electronics, and heavy machinery meet the highest standards of durability, strength, and reliability. South Korea, recognized for its technological prowess and advanced manufacturing capabilities, has emerged as a hub for top-tier quenching system manufacturers and suppliers. This article offers a comprehensive look at the leading companies in South Korea, their innovative technologies, and the industries they serve, providing valuable insights for international buyers, OEM partners, and industrial professionals.

Understanding Quenching Systems

What is a Quenching System?

A quenching system is a specialized piece of equipment used in the heat treatment of metals. The primary function of a quenching system is to rapidly cool a heated metal part, such as steel or aluminum, to lock in specific mechanical properties. The process is essential for achieving desired characteristics like hardness, toughness, and resistance to wear.

The quenching process typically involves heating a metal component to a high temperature and then quickly cooling it by immersing it in a quenching medium. The choice of medium—water, oil, polymer solution, or gas—depends on the required cooling rate and the specific properties desired in the final product.

Types of Quenching Systems

- Water Quenching Systems: Provide the fastest cooling rates, ideal for applications that require maximum hardness.

- Oil Quenching Systems: Offer moderate cooling rates, reducing the risk of cracking and distortion in the treated parts.

- Polymer Quenching Systems: Allow for adjustable cooling rates and are more environmentally friendly than oil-based systems.

- Gas Quenching Systems: Used in vacuum furnaces for precise temperature control and minimal oxidation, suitable for high-value components.

The Importance of Quenching Systems in Modern Manufacturing

Quenching systems are indispensable in industries that demand high-performance materials. The ability to control the cooling rate and uniformity directly influences the microstructure and, consequently, the mechanical properties of the metal. This makes quenching systems a cornerstone of quality assurance in metalworking and manufacturing.

The South Korean Heat Treatment Industry

South Korea's manufacturing sector is renowned for its innovation, efficiency, and adherence to international quality standards. The country's heat treatment industry is no exception, with numerous companies investing heavily in research and development to stay ahead of global trends. South Korean manufacturers are known for their ability to deliver customized, energy-efficient, and environmentally responsible quenching solutions to clients worldwide.

Key Drivers of Growth

- Technological Innovation: South Korean companies are at the forefront of automation, digitalization, and smart manufacturing.

- Export Orientation: Many manufacturers focus on serving international markets, offering OEM and ODM services tailored to client needs.

- Sustainability: There is a growing emphasis on energy efficiency and environmentally friendly processes, driven by both regulatory requirements and market demand.

Top Quenching System Manufacturers And Suppliers in South Korea

SAMWOO FMC Co., Ltd.

SAMWOO FMC Co., Ltd. is a leading player among quenching system manufacturers and suppliers in South Korea. The company is known for its comprehensive range of heat treatment equipment, including water, oil, and polymer quenching systems. SAMWOO FMC's solutions are designed for high efficiency, safety, and reliability, making them a preferred choice for demanding industrial applications.

Key Features:

- Customizable quenching systems to meet specific client requirements.

- Advanced automation and process control for consistent quality.

- Strong focus on energy savings and operational safety.

Industries Served:

- Automotive manufacturing

- Steel and metal processing

- Heavy machinery and equipment

Thermvac Inc.

Thermvac Inc. stands out as a pioneer in vacuum furnace technology and high-performance quenching systems in South Korea. The company has been recognized for its contributions to national infrastructure and is a trusted supplier to industries requiring advanced heat treatment solutions.

Key Features:

- A wide range of vacuum furnaces, including heavy-duty gas quenching systems.

- Ultra-high temperature furnaces capable of reaching up to 3,000°C.

- Two-chamber graphitization furnaces for rapid cooling and energy efficiency.

Industries Served:

- Aerospace and defense

- Advanced materials processing

- Electronics and semiconductor manufacturing

Dongkuk Industries Co., Ltd.

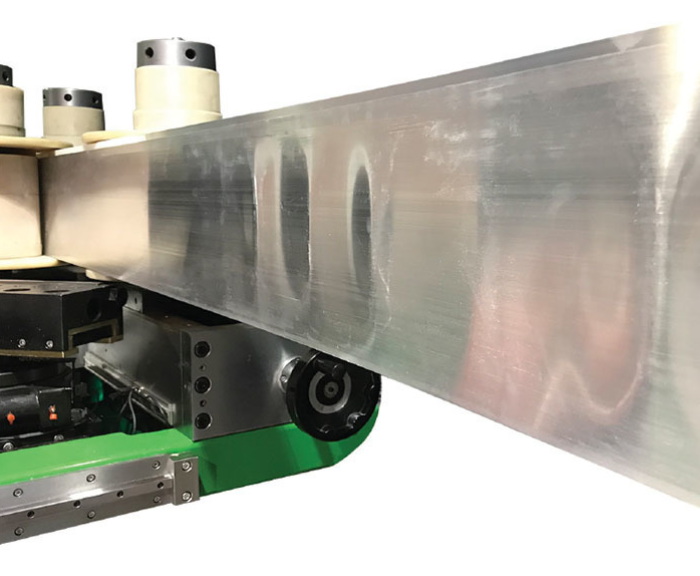

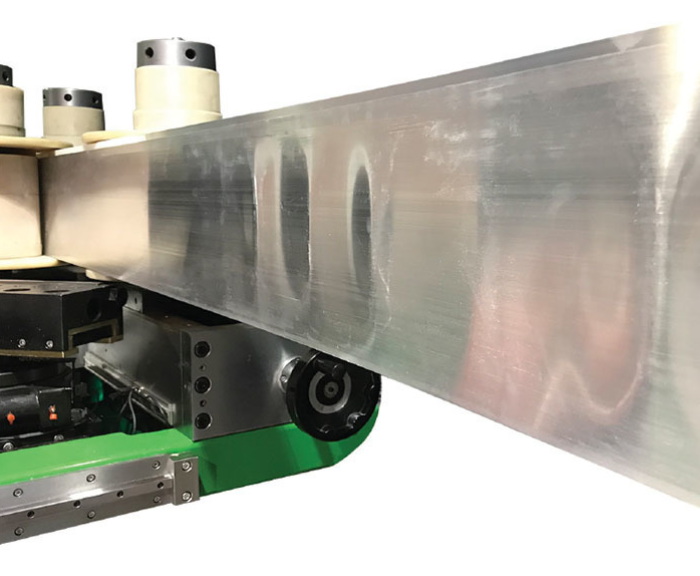

Dongkuk Industries Co., Ltd. is the largest producer of cold-rolled medium and high carbon steel strip in South Korea. The company has made significant investments in cutting-edge quenching technology, notably the EBNER HICON/H2Q hydrogen quenching system, which is the first of its kind in East Asia. This innovation has set new benchmarks for product quality and process efficiency.

Key Features:

- Hydrogen-based quenching for superior metallurgical properties.

- SmartFlat automatic flatness supervision for consistent product quality.

- Integrated hardening and tempering lines for end-to-end processing.

Industries Served:

- Steel strip production

- Automotive and construction materials

SAC Co., Ltd.

SAC Co., Ltd. is a fast-growing manufacturer and exporter specializing in environmentally friendly quenching and low-pressure carburizing systems. The company's product lineup includes oil quenching systems and solutions for a variety of heat treatment applications, catering to both domestic and international clients.

Key Features:

- Environmentally responsible manufacturing processes.

- Export-oriented, with a strong focus on international markets.

- Customizable solutions for diverse industry needs.

Other Notable Suppliers

- APN Co., Ltd.: Specializes in post-weld heat treatment (PWHT) services and advanced heat treatment equipment.

- HSTec: Offers high-precision custom machine parts and industrial automation, including heat treatment processes.

- Samwon Techno Co., Ltd.: Provides comprehensive metal heat treatment contracting services.

- RK Industrial Enterprises: Supplies furnace automation and accessories, supporting the broader heat treatment industry.

Key Technologies and Innovations

Automation and Digital Control

South Korean quenching system manufacturers and suppliers are leaders in integrating automation and digital control into their equipment. Features such as programmable logic controllers (PLCs), touch-screen interfaces, and real-time monitoring systems enable precise temperature control, uniform cooling, and enhanced safety.

Energy Efficiency and Sustainability

With increasing global focus on sustainability, South Korean manufacturers have prioritized energy-efficient designs. Innovations include:

- Insulated quench tanks to minimize heat loss.

- Active cooling systems to optimize energy use.

- Heat recovery processes that reduce operational costs and environmental impact.

Customization and Flexibility

The ability to deliver customized solutions is a hallmark of top South Korean quenching system manufacturers and suppliers. Whether it's adjusting cooling rates, integrating with existing production lines, or developing specialized quenching media, these companies are adept at meeting the unique needs of their clients.

Advanced Quenching Media

Research and development efforts have led to the creation of new quenching media, such as advanced polymer solutions and hydrogen-based systems. These innovations offer improved cooling performance, reduced environmental impact, and greater process control.

Applications of Quenching Systems

Quenching systems are essential in a wide range of industries, each with specific requirements:

- Automotive: Hardening gears, shafts, and other critical components to ensure long-term durability and performance.

- Aerospace: Treating high-strength alloys used in aircraft and spacecraft for maximum reliability.

- Electronics: Ensuring the reliability and longevity of metal parts in sensitive electronic devices.

- Construction: Producing robust steel and metal components for infrastructure projects.

- Tool and Die Making: Achieving precise hardness and wear resistance for manufacturing tools and dies.

Choosing the Right Quenching System Manufacturer or Supplier

Selecting the right quenching system manufacturer or supplier is a crucial decision for any industrial operation. Here are key factors to consider:

- Technical Expertise: Assess the company's experience, technological capabilities, and track record in delivering successful projects.

- Product Range: Ensure the supplier offers the specific type of quenching system required for your application.

- Customization: Look for manufacturers who are willing to tailor their solutions to your unique needs.

- After-Sales Support: Reliable maintenance, training, and technical support are essential for long-term success.

- Certifications and Compliance: Verify that the manufacturer adheres to international quality and safety standards, such as ISO certifications.

Trends Shaping the Future of Quenching Systems in South Korea

Digitalization and Smart Manufacturing

The adoption of Industry 4.0 principles is transforming the heat treatment sector in South Korea. Digital twins, IoT-enabled sensors, and predictive maintenance are becoming standard features in modern quenching systems. These technologies enable real-time data collection, process optimization, and reduced downtime.

Environmental Regulations and Green Manufacturing

South Korea's commitment to environmental protection is driving manufacturers to adopt greener processes. This includes the use of environmentally friendly quenching media, waste heat recovery systems, and the reduction of hazardous emissions.

Global Partnerships and Export Growth

South Korean quenching system manufacturers and suppliers are increasingly forming partnerships with international companies, expanding their reach and influence in global markets. Their reputation for quality, reliability, and innovation makes them preferred partners for OEMs, wholesalers, and production companies worldwide.

Conclusion

South Korea has firmly established itself as a global leader in the field of quenching system manufacturing and supply. The country's top manufacturers—such as SAMWOO FMC, Thermvac Inc., Dongkuk Industries, and SAC Co., Ltd.—are renowned for their advanced technologies, commitment to quality, and ability to deliver customized solutions for a wide range of industries. Whether you are seeking high-speed water quenching systems, energy-efficient oil quenching solutions, or cutting-edge hydrogen-based technologies, South Korea offers a wealth of expertise and innovation.

For international buyers, OEM partners, and industrial professionals, partnering with a South Korean quenching system manufacturer or supplier ensures access to world-class products, technical support, and a commitment to continuous improvement. As the industry continues to evolve, South Korea's manufacturers are well-positioned to lead the way in meeting the demands of modern manufacturing.

Frequently Asked Questions

1. What are the main types of quenching systems offered by South Korean manufacturers?

South Korean quenching system manufacturers and suppliers typically offer water, oil, polymer, and gas quenching systems, each designed for specific cooling rates and metallurgical outcomes.

2. How do South Korean quenching systems ensure energy efficiency?

Manufacturers incorporate insulated tanks, active cooling, and heat recovery systems, along with advanced automation, to minimize energy consumption and maximize operational efficiency.

3. Are South Korean quenching system suppliers experienced in exporting?

Yes, many leading suppliers such as SAC Co., Ltd. and SAMWOO FMC have extensive experience exporting to global markets, providing OEM and customized solutions for international clients.

4. What industries benefit most from South Korean quenching systems?

Key industries include automotive, aerospace, electronics, construction, and tool manufacturing, all of which require precise heat treatment for enhanced material properties.

5. How can I contact top quenching system manufacturers and suppliers in South Korea?

Most manufacturers have dedicated export departments and can be contacted through their official websites or via B2B platforms specializing in industrial equipment.