Content Menu

● What Is Extrusion Technology?

● Why Choose German Extrusion Production Line Manufacturers and Suppliers?

>> Engineering Precision

>> Integrated Automation and Industry 4.0

>> Advanced Materials Compatibility

>> High Customizability

>> Green Technology and Sustainability

● Top Extrusion Production Line Manufacturers and Suppliers in Germany

>> 1. Reifenhäuser Group

>> 2. Leistritz Extrusionstechnik GmbH

>> 3. Coperion GmbH

>> 4. Battenfeld-Cincinnati

>> 5. Breyer GmbH Maschinenfabrik

>> 6. OKE Group GmbH

>> 7. BWF Profiles GmbH

>> 8. Extrudex Kunststoffmaschinen GmbH

>> 9. Hans Weber Maschinenfabrik GmbH

>> 10. Technoform Kunststoffprofile GmbH

● Applications and Industry Trends

>> Future Trends Driving Innovation:

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What makes German extrusion line manufacturers different from others globally?

>> 2. Can these manufacturers provide customized extrusion lines for niche applications?

>> 3. Do German manufacturers support overseas installation and training?

>> 4. Are German extrusion lines energy-efficient and eco-friendly?

>> 5. How can I evaluate and select the best supplier for my needs?

Germany stands as a global leader in manufacturing and engineering, particularly renowned for innovation, quality, and precision in industrial machinery. One sector where German engineering excellence is especially prominent is in extrusion technology — a transformative process that plays a central role in producing materials used across industries such as automotive, construction, packaging, energy, and consumer electronics.

German extrusion production line manufacturers and suppliers are recognized for delivering highly efficient, tailor-engineered solutions that meet the stringent international standards demanded by modern manufacturing. If you're a stakeholder seeking an OEM partner, a wholesaler, or a brand in search of a reliable extrusion line solution, understanding the capabilities of Germany's top suppliers is essential to your sourcing strategy.

This article offers a deep dive into the most respected extrusion production line manufacturers and suppliers in Germany, highlighting their technologies, innovations, areas of specialization, and value-added services.

What Is Extrusion Technology?

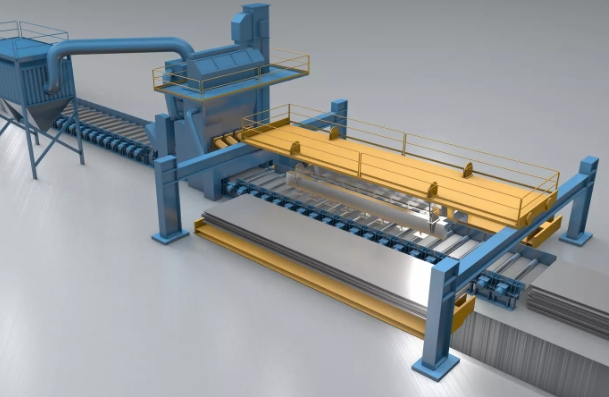

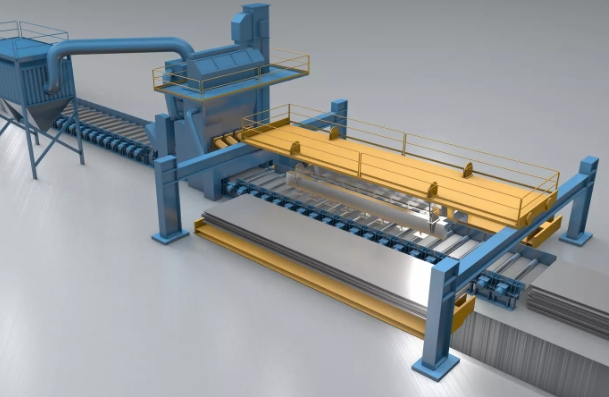

Extrusion is a continuous manufacturing process where raw material is pushed through a shaped die to create objects with a fixed cross-sectional profile. The materials used can range from plastics and metals to ceramics or food-based products. In extrusion production lines, every stage, from material feeding and melting to shaping and cooling, is designed for precision, speed, and versatility.

Modern extrusion production line manufacturers and suppliers offer highly specialized systems tailored to specific industries. They deliver complete turnkey machinery including extruders, dies, cooling systems, take-off units, hauling systems, and control interfaces — all integrated under robust automation protocols.

Why Choose German Extrusion Production Line Manufacturers and Suppliers?

German engineering is not driven by mass production alone but by the pursuit of optimized performance, precision, and sustainability. Here's why countless global companies choose German extrusion production line manufacturers and suppliers:

Engineering Precision

Germany boasts some of the most advanced mechanical engineering institutions and manufacturing ecosystems in the world. German extrusion lines are built with meticulous attention to detail, ensuring longevity and exceptional output quality.

Integrated Automation and Industry 4.0

German manufacturers are pioneers in developing intelligent extrusion systems with integrated IoT (Internet of Things) features, remote diagnostics, real-time control dashboards, and automated adjustment capabilities. This dramatically improves efficiency, reduces downtime, and ensures consistency in quality.

Advanced Materials Compatibility

Leading German extrusion production line manufacturers and suppliers develop systems for processing a wide range of materials, including recyclable plastics, advanced composites, multilayer films, and specialty polymers.

High Customizability

Whether you need a compact lab-scale extruder or a full-scale factory line, German producers offer customization down to the component level. This includes screw design, extrusion speed, temperature control, and output formatting.

Green Technology and Sustainability

With environmental regulations becoming stricter worldwide, energy-saving features, eco-friendly material solutions, and low-waste systems offered by German suppliers add important value. Many integrate recycling capabilities directly into the line.

Top Extrusion Production Line Manufacturers and Suppliers in Germany

Below are some of the most respected names in Germany's extrusion equipment sector:

1. Reifenhäuser Group

Founded: 1911 — Headquarters: Troisdorf, Germany

Specialization: Blown and cast film extrusion, nonwoven lines

Reifenhäuser is a global leader in extrusion technology, known for high-speed plastic film and sheet extrusion systems used in medical, packaging, and industrial applications. Their "Reicofil" solutions are internationally recognized for medical-grade nonwovens. Reifenhäuser is synonymous with innovation in multilayer film production, high output rates, and process stability.

Key Innovations:

- Modular line concepts

- Integrated digital control systems (Extrusioneers Platform)

- Energy-optimized layout for better resource usage

2. Leistritz Extrusionstechnik GmbH

Founded: 1905 — Headquarters: Nürnberg, Germany

Specialization: Twin-screw extrusion, compounding, pharma and food industries

Leistritz is a pioneer in co-rotating twin-screw extruders and offers extensive expertise in customized compounding lines. Their machines are widely used in high-performance industries like pharmaceuticals, where consistency and hygiene are vital.

Key Innovations:

- Laboratory to industrial-scale extruders

- Modular configuration for rapid product swaps

- Advanced screw geometries for specialty materials

3. Coperion GmbH

Founded: 1879 — Headquarters: Stuttgart, Germany

Specialization: Compounding, bulk materials handling

Coperion is one of the world's largest and most diversified extrusion production line manufacturers and suppliers. Their ZSK series twin-screw extruders serve sectors ranging from plastics to chemicals and food. Coperion also offers entire turnkey systems with feeding, conveying, and downstream machinery.

Key Innovations:

- Smart line integration with MES compatibility

- Optimized screw profiles for 24/7 industrial operation

- Process analytics for real-time OEE improvement

4. Battenfeld-Cincinnati

Founded: 1943 — Headquarters: Bad Oeynhausen, Germany

Specialization: Plastic pipe, profile, sheets, and WPC extrusion

Battenfeld-Cincinnati delivers custom extrusion lines with a focus on environmental sustainability and premium quality. Their extrusion systems are highly popular in infrastructure, agriculture, and construction segments.

Key Innovations:

- GreenPipe technology for energy-efficient extrusion

- Multi-layer co-extrusion for complex product builds

- Flexible line layouts for small or large batch production

5. Breyer GmbH Maschinenfabrik

Founded: 1949 — Headquarters: Singen, Germany

Specialization: Sheet extrusion, optical films, separator film machines

Breyer focuses on high-speed sheet extrusion equipment suitable for architectural, automotive, and photovoltaic industries. The company has a strong history in fine-tuning surface finishes and dimensional tolerances.

Key Innovations:

- Sheet lines for high-gloss acrylic and polycarbonate

- Advanced calendaring and cooling systems

- Developments in battery separator film

6. OKE Group GmbH

Specialization: Plastic profile extrusion for automotive, furniture, and appliance sectors

OKE Group focuses on high-accuracy profile extrusion using co-extrusion and specialized tooling for high-volume, low-deviation production.

7. BWF Profiles GmbH

Specialization: Technical plastic profiles, LED covers, and transport solutions

Part of the BWF Group, this manufacturer caters to harsh operating conditions with advanced cooling profile designs and recyclable plastic options.

8. Extrudex Kunststoffmaschinen GmbH

Specialization: High-performance single-screw extruders

Extrudex supplies reliable, low-maintenance systems with CE-certified standards. Used broadly in utilities, automotive, and protective sheathing applications.

9. Hans Weber Maschinenfabrik GmbH

Specialization: Tailored profile extrusion solutions

Hans Weber excels at offering integrable lines adapted to customer floor plans and process requirements. Their machines are robust and widely used across SMEs and large OEM organizations.

10. Technoform Kunststoffprofile GmbH

Specialization: High-performance thermoplastic profiles for building and industry

Technoform shines in energy-efficient product innovations, such as insulation plugs for aluminum window systems. Their extrusion lines are designed to enable low-carbon manufacturing.

Applications and Industry Trends

German extrusion production line manufacturers and suppliers serve nearly every industrial sector:

- Automotive: Seals, trims, cable ducts, and lightweight structures.

- Construction: Window frames, insulation panels, luxury cladding, and drainage pipes.

- Medical & Pharma: High-purity tubing, catheter sheaths, biocompatible films.

- Electronics: Precision conduit for wires and fiber optic cable protection.

- Renewable Energy: Solar film panels, battery separators, recycled polymer applications.

Future Trends Driving Innovation:

- Recyclability and Circular Economy: Closed-loop systems integrating in-line granulation and re-extrusion.

- Digital Twins: Virtual modeling of machines for predictive maintenance.

- Material Science Advancements: Growing use of biodegradable, barrier, and conductive materials.

Conclusion

Germany's extrusion production line manufacturers and suppliers offer unmatched quality, engineering sophistication, and innovation. With growing demand across diverse sectors such as automotive, electronics, medical, packaging, and infrastructure, choosing a trusted and experienced German partner could be the key to operational success and sustainability.

Whether you require turnkey solutions, customized systems, or high-efficiency OEM cooperation, German suppliers bring decades of excellence and futuristic capabilities to the table.

Frequently Asked Questions (FAQ)

1. What makes German extrusion line manufacturers different from others globally?

German manufacturers prioritize precision engineering, stringent quality standards, and broad customization options. Their integration of smart technologies and dedication to sustainable solutions make them world leaders.

2. Can these manufacturers provide customized extrusion lines for niche applications?

Yes. Most German extrusion production line manufacturers and suppliers provide tailor-made solutions, including for highly specific applications like battery films, medical tubing, or triple-layer pipes.

3. Do German manufacturers support overseas installation and training?

Absolutely. Global support networks, remote diagnostics, and multilingual training programs are standard offerings from most top-tier suppliers.

4. Are German extrusion lines energy-efficient and eco-friendly?

Yes. Energy savings and sustainable operation are at the heart of German engineering, with many lines featuring integrated recycling, waste minimization, and process optimization technologies.

5. How can I evaluate and select the best supplier for my needs?

Identify your technical needs, production scale, industry requirements, and budget. Then, seek consultations and comparative quotes from multiple manufacturers—ideally those with proven experience in your target market sector.