Content Menu

● Understanding Extrusion Production Lines

>> What Is Extrusion?

>> Types of Extrusion Production Lines

● Australia's Extrusion Production Line Industry: Industry Overview

>> Key Industry Trends in Australia

● Leading Extrusion Production Line Manufacturers and Suppliers in Australia

>> 1. Capral Aluminium

>> 2. Ullrich Aluminium

>> 3. Aluminium Industries Australia

>> 4. G.James Glass & Aluminium

>> 5. Interfab

>> 6. Local Niche Providers

● Advantages of Partnering with Australian Manufacturers

>> Superior Quality Assurance

>> Comprehensive Customization and OEM Support

>> Innovation-Driven Production

>> Commitment to Sustainability

● How to Choose the Right Manufacturer or Supplier for Extrusion Production Lines

>> 1. Technical Expertise and Experience

>> 2. Quality and Compliance Certifications

>> 3. After-Sales Service and Support

>> 4. Flexibility and Custom Order Capability

>> 5. Cost vs. Value Analysis

● The Global Perspective: Role of Chinese OEM Suppliers for Overseas Buyers

● Common Applications for Extrusion Production Lines

● Future Trends in Extrusion Production Line Technology

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What factors should I consider when selecting an extrusion production line manufacturer in Australia?

>> 2. How does Australian extrusion technology differ from that of other leading countries?

>> 3. Can Chinese OEM extrusion production line suppliers work with overseas buyers for customized solutions?

>> 4. What industries benefit most from Australian extrusion production lines?

>> 5. Is it possible to integrate new extrusion technology into an existing production line?

Extrusion technology stands as a pivotal pillar in modern manufacturing. It enables the creation of consistent, high-quality profiles and components essential in industries ranging from construction and automotive to electronics and furnishings. As Australia's industrial landscape matures, the demand for cutting-edge extrusion production lines has surged, urging manufacturers and suppliers to innovate and expand capabilities to meet global standards.

For companies and OEM clients worldwide, partnering with top-tier Extrusion Production Line Manufacturers and Suppliers in Australia can mean the difference between operational excellence and costly inefficiencies. This article delivers a detailed overview of Australia's leading extrusion producers, examines industry trends, highlights key considerations for collaboration, and uncovers evolving technological advancements shaping the future of extrusion production lines.

Understanding Extrusion Production Lines

What Is Extrusion?

Extrusion is a manufacturing process where material—typically metals like aluminium or plastics—is forced through a specifically shaped die to produce a continuous profile of a fixed cross-section. This process allows for efficient mass manufacturing of complex shapes such as tubes, rods, window frames, and more. The resulting products are integral to machinery, construction, transportation, and countless end-use applications.

Types of Extrusion Production Lines

Extrusion production lines come in various configurations adapted to different materials and output requirements:

- Aluminium Extrusion Lines: Predominantly used within automotive, aerospace, and building industries due to aluminium's lightweight and corrosion-resistant nature.

- Plastic Extrusion Lines: Vital for manufacturing pipes, packaging materials, sheathing, and consumer goods.

- Custom Extrusion Lines: Designed for bespoke applications, these lines offer flexibility in profile shape, output quantity, raw materials, and automation scope, catering perfectly to OEM demands.

Australia's Extrusion Production Line Industry: Industry Overview

Australia has witnessed sustained growth in extrusion manufacturing driven by infrastructure projects, increased demand for sustainable materials, and innovations in lightweight technologies. This growth has created a fertile environment for extrusion machine manufacturers and suppliers to innovate and refine their offerings.

Key Industry Trends in Australia

- Rising Demand for Aluminium Extrusions: The expanding construction and automotive sectors are key drivers.

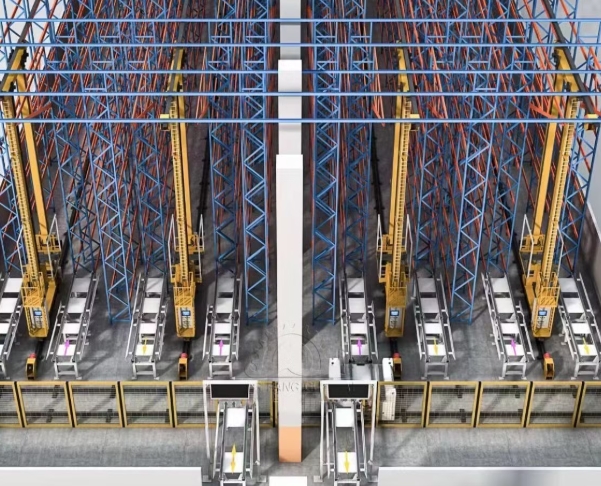

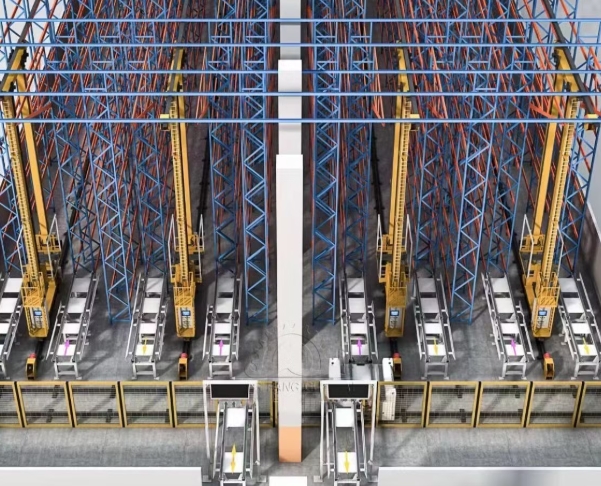

- Shift Toward Automation: Smart extrusion lines featuring automated handling, sensing, and control are becoming industry standards.

- Sustainability Focus: Australian manufacturers embrace eco-friendly practices, incorporating energy-efficient processes and recyclable materials.

- OEM and Customization Services: Suppliers increasingly provide full-service OEM solutions, including design, prototyping, tooling, and after-sales support to meet specific client needs.

Leading Extrusion Production Line Manufacturers and Suppliers in Australia

Below, we explore several key players that define Australia's extrusion manufacturing landscape.

1. Capral Aluminium

A titan in the Australian aluminium extrusion arena, Capral Aluminium leads with extensive manufacturing capacity complemented by advanced extrusion equipment. Its nationwide manufacturing centers ensure dynamic supply to diverse sectors.

- Leveraging innovative R&D for profile customization.

- Providing technical assistance and comprehensive customer support.

- Maintaining strict quality control across extrusion processes.

2. Ullrich Aluminium

Ullrich Aluminium is known for its flexibility in serving both SMEs and large-scale contracts, emphasizing custom profile extrusion and broad product variety. Their expertise supports domestic and international clients with dependable delivery timelines.

- Offers a vast profile catalogue suitable for varying industrial requirements.

- Provides scalable production batches.

- Shows a commitment to technical service excellence.

3. Aluminium Industries Australia

Focusing heavily on bespoke extrusion solutions, Aluminium Industries Australia stands out for its end-to-end project management ability — from design engineering to delivery.

- Skilled at handling complex alloy mixes and specialized finishes.

- Implements rigorous quality assurance protocols.

- Offers comprehensive OEM services.

4. G.James Glass & Aluminium

With roots dating back over a century, G.James excels in combining extrusion, fabrication, and finishing. It supplies architectural and construction sectors with integrated solutions.

- Employs vertically integrated operational practices.

- Designs in-house dies and tooling systems.

- Meets international standards with a focus on durability and aesthetics.

5. Interfab

Interfab focuses on precision extrusion and custom metalworking solutions. Their strengths lie in combining automation with flexible project scales from prototyping to full production.

- Utilizes high automation levels to increase efficiency.

- Offers prototyping and small-batch manufacturing.

- Provides strong project oversight and integrated service.

6. Local Niche Providers

Apart from major suppliers, Australia hosts many specialized manufacturers focusing on niche alloys, rapid prototyping, or green extrusion technologies. These smaller enterprises offer agility and focus unmatched by larger corporations, particularly useful for innovative product development or low-volume needs.

Advantages of Partnering with Australian Manufacturers

Superior Quality Assurance

Australia's strict manufacturing and environmental standards guarantee extrusion products and machines that meet or exceed global requirements, assuring customers of reliability and consistency.

Comprehensive Customization and OEM Support

Australian extrusion line suppliers provide extensive customization options and support OEM operations, delivering solutions tailored to brand requirements and product specifications.

Innovation-Driven Production

Investments in high-efficiency, automated extrusion lines enable faster turnaround and higher throughput. These advancements improve production accuracy and reduce material waste.

Commitment to Sustainability

Environmental responsibility is key, with manufacturers adopting renewable energy, recycling scrap material, and optimizing processes for lower carbon footprints.

How to Choose the Right Manufacturer or Supplier for Extrusion Production Lines

Selecting the ideal extrusion production line partner affects product quality, operational efficiency, and cost-effectiveness. Consider these factors carefully:

1. Technical Expertise and Experience

Choose firms with proven experience in your application field — whether it's automotive parts, building materials, or consumer products. Review case studies and previous projects for confidence.

2. Quality and Compliance Certifications

Look for ISO 9001 for quality management, ISO 14001 for environmental standards, and any industry-specific certifications depending on your project's needs.

3. After-Sales Service and Support

Robust after-sales support ensures smooth installation, training, troubleshooting, and maintenance services, minimizing downtime and safeguarding productivity.

4. Flexibility and Custom Order Capability

Verify whether suppliers can accommodate custom dies, profile variations, and branding needs, especially when volume or design changes occur frequently.

5. Cost vs. Value Analysis

Evaluate not just initial purchase price but total cost of ownership, including energy consumption, maintenance, yield rates, and equipment lifespan.

The Global Perspective: Role of Chinese OEM Suppliers for Overseas Buyers

While Australian manufacturers deliver premium extrusion lines, many foreign brands engage Chinese OEMs for affordable, scalable solutions. Chinese extrusion equipment suppliers, seasoned in OEM partnerships, offer:

- Competitive pricing with no compromise on engineering.

- Quick scalability for bulk manufacturing.

- Global logistics expertise.

- Familiarity with international standards and export compliance.

For overseas buyers, blending Australia's advanced technology insights with China's manufacturing capacity can deliver optimized solutions tailored to budget and quality demands.

Common Applications for Extrusion Production Lines

Australia and global markets rely on extrusion lines for diverse industrial sectors:

- Construction: Fabrication of window frames, curtain walls, partitions, and structural components.

- Automotive: Lightweight chassis, engine components, and interior/exterior panels.

- Electronics: Heat sinks, connectors, casings.

- Transportation: Rail and marine body frames.

- Renewable Energy: Solar panel supports and wind turbine parts.

The versatility of extrusion platforms makes them indispensable across these and many emerging industries.

Future Trends in Extrusion Production Line Technology

The next decade promises significant developments:

- Advanced Automation: Robotics and AI enhance precision and throughput while reducing human error.

- Smart Monitoring and IoT Integration: Sensors and cloud systems enable predictive maintenance and production optimization in real-time.

- Sustainability Gains: Zero-waste manufacturing, renewable energy use, and enhanced recycling of extrusion scrap become standard.

- Material Innovations: Development of hybrid alloys and composite extrusion pushes boundaries for performance and design flexibility.

Manufacturers and suppliers at the forefront embrace these shifts, ensuring clients maintain market competitiveness.

Conclusion

Australia's extrusion production line sector exemplifies high-quality manufacturing supported by innovation, adaptability, and sustainability. Leading manufacturers such as Capral, Ullrich, Aluminium Industries Australia, G.James, and Interfab, among others, collectively offer a breadth of expertise capable of delivering tailored solutions for global OEMs, wholesalers, and brands.

Choosing the right extrusion production line supplier goes beyond cost, emphasizing technical proficiency, flexible customization, strong after-sales service, and compliance with rigorous quality standards. Additionally, exploring integrated sourcing strategies involving both Australian and Chinese OEM suppliers can enhance cost efficiency and global reach.

As industry demands evolve with automation, sustainability, and smart manufacturing, partnering with top-tier extrusion line manufacturers and suppliers in Australia ensures ongoing production excellence, reliability, and growth opportunities.

Frequently Asked Questions (FAQ)

1. What factors should I consider when selecting an extrusion production line manufacturer in Australia?

Focus on the manufacturer's technical expertise for your application, quality and environmental certifications, customization offerings, after-sales support, and cost versus overall value.

2. How does Australian extrusion technology differ from that of other leading countries?

Australian manufacturers emphasize stringent quality and environmental standards, innovate automation capabilities, and integrate sustainability deeply into production practices, often surpassing some global norms.

3. Can Chinese OEM extrusion production line suppliers work with overseas buyers for customized solutions?

Yes. Reputable Chinese OEM suppliers have extensive experience providing tailored designs and meeting various international compliance standards, supporting global brand requirements effectively.

4. What industries benefit most from Australian extrusion production lines?

Construction, automotive, electronics, transportation, and renewable energy sectors predominantly benefit, each relying on quality profiles and reliable supply chains.

5. Is it possible to integrate new extrusion technology into an existing production line?

Most leading suppliers offer retrofit and upgrade services, enabling clients to enhance existing lines with modern automation, control systems, and tooling technologies without full replacement.