Content Menu

● Overview of the Portuguese Extrusion Press Machine Market

● Leading Manufacturers and Suppliers in Portugal

>> Exlabesa Portugal: Setting the Benchmark

>>> Facility and Production Capabilities

>>> Advanced Technology and OEM Services

>>> Commitment to Sustainability

>>> Strategic Location and Logistics

>> SMS Group: Technology Provider to the Industry

>>> Technological Innovations

● Technological Advancements in Extrusion Press Machines

● Applications and Market Segments

>> Construction

>> Transportation

>> Infrastructure

>> Renewable Energy

>> Electrical and Electronics

● Sustainability and Certifications

● Market Trends and Future Outlook

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What are the main advantages of sourcing extrusion press machines from Portugal?

>> 2. Which alloys can be processed by top extrusion press machine manufacturers and suppliers in Portugal?

>> 3. How do Portuguese manufacturers ensure the sustainability of their extrusion press machines and products?

>> 4. What technological innovations are implemented in modern extrusion press machines?

>> 5. What is the production capacity of the largest extrusion press machine facilities in Portugal?

Portugal has become a significant hub for the extrusion press machine industry in Europe, offering advanced manufacturing capabilities, innovative technology, and a strong commitment to sustainability. As global demand for high-quality aluminum profiles continues to rise, Portugal's leading extrusion press machine manufacturers and suppliers have positioned themselves as reliable partners for international brands, wholesalers, and OEM customers. This comprehensive article explores the landscape of Portugal's extrusion press machine sector, highlights key players, discusses technological advancements, and examines the market's focus on sustainability and quality.

Overview of the Portuguese Extrusion Press Machine Market

The extrusion press machine market in Portugal has witnessed remarkable growth over the past decade. This expansion is fueled by the country's strategic location within Europe, robust infrastructure, and the increasing demand for aluminum profiles in diverse sectors such as construction, transportation, energy, and electronics. Portugal's extrusion press machine manufacturers and suppliers are known for their ability to deliver customized solutions, high production capacities, and adherence to international standards.

Several factors contribute to the market's dynamism:

- Growing Demand for Aluminum Profiles: Aluminum's lightweight, corrosion-resistant, and recyclable properties make it the material of choice for modern construction, automotive, and renewable energy applications.

- Investment in Technology: Portuguese manufacturers continuously invest in state-of-the-art extrusion press machines and automation, ensuring efficiency, precision, and scalability.

- Sustainability Initiatives: There is a strong emphasis on using recycled materials, reducing energy consumption, and achieving environmental certifications, aligning with global sustainability goals.

Leading Manufacturers and Suppliers in Portugal

Exlabesa Portugal: Setting the Benchmark

Exlabesa is a prominent name among extrusion press machine manufacturers and suppliers in Portugal. With decades of experience in the aluminum industry, Exlabesa has established itself as a leader in innovation, quality, and sustainability.

Facility and Production Capabilities

Exlabesa's Portuguese facility, located in Coimbra, is a testament to the company's commitment to excellence. The factory covers over 86,000 square meters, with 10,000 square meters dedicated to production under roof. Recent investments totaling €25 million have enabled the installation of two advanced 2,800-tonne press lines, giving the facility an annual capacity of 16,000 tonnes of extruded aluminum profiles.

Plans for expansion are already underway, with the factory set to grow to 31,000 square meters and add three more presses (two 3,500-tonne and one 4,500-tonne), which will boost annual production to over 45,000 tonnes. This scale of operation positions Exlabesa as one of the largest extrusion press machine manufacturers and suppliers not only in Portugal but in all of Europe.

Advanced Technology and OEM Services

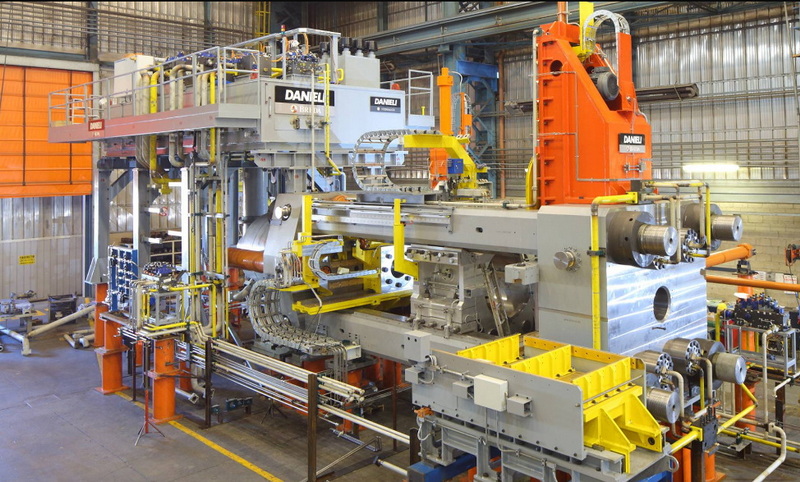

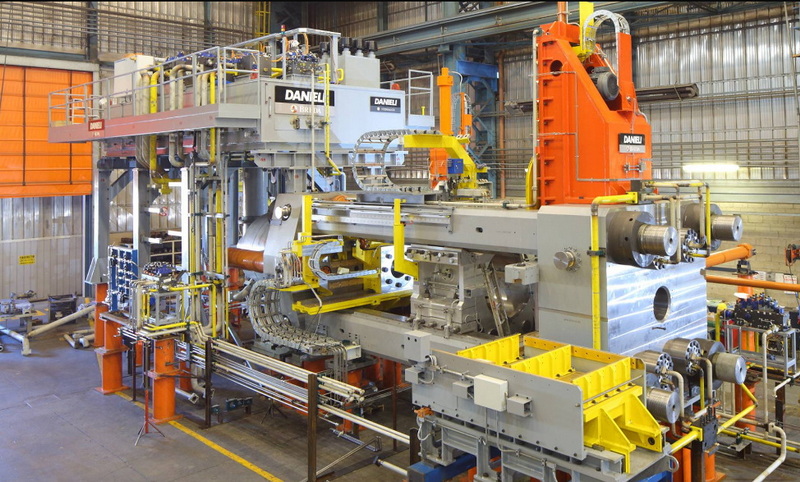

Exlabesa's production lines are equipped with cutting-edge machinery supplied by global technology leaders such as SMS Group. The facility can extrude all 6000 series aluminum alloys, including 6005, 6060, 6061, 6063, 6082, 6101, and 6106, using billets up to 8 inches in diameter. The integration of a vertical powder coating line enables the finishing of profiles up to 7,200 mm in length, meeting the requirements of demanding architectural and industrial applications.

As a trusted OEM partner, Exlabesa provides tailored solutions for international brands, wholesalers, and manufacturers. Their expertise encompasses product design, rapid prototyping, precision extrusion, surface treatment, and logistics, ensuring that clients receive end-to-end support throughout the project lifecycle.

Commitment to Sustainability

Sustainability is at the core of Exlabesa's operations. The company utilizes RE-local recycled aluminum, which boasts a certified carbon footprint of only 2.95 kg CO₂e per kilogram of aluminum—significantly lower than the industry average. Exlabesa's environmental credentials are further reinforced by certifications such as ISO 9001, CE marking, Qualicoat, and the Alu+C- environmental label. These standards guarantee not only product quality but also responsible and eco-friendly manufacturing practices.

Strategic Location and Logistics

Exlabesa's central location in Portugal enables rapid distribution to key markets in Portugal, Spain, and France. The company's integration with a broader European logistics network ensures timely delivery and efficient supply chain management, making it a preferred partner for clients across the continent.

SMS Group: Technology Provider to the Industry

While Exlabesa stands out as a leading manufacturer, SMS Group plays a pivotal role as a technology provider to the Portuguese extrusion press machine industry. SMS Group is renowned for its engineering excellence and innovative solutions, supplying advanced extrusion press machines to manufacturers throughout Europe.

Technological Innovations

SMS Group's extrusion press machines are characterized by:

- Short-Stroke, Front-Loader Design: These presses feature FEM-optimized, pre-stressed frames that deliver high rigidity and long service life, ensuring consistent performance even under demanding production schedules.

- HybrEx® Hybrid Drive Systems: By combining electric servomotors with hydraulic drives, HybrEx® presses achieve up to 55% energy savings and a 20% increase in productivity compared to conventional systems.

- EcoDraulic Control Systems: Intelligent start/stop controls further reduce energy consumption by up to 10%, contributing to lower operational costs and a reduced environmental footprint.

- Automated Quality Control: Integrated systems such as PCAST dotnet enable real-time process monitoring, rapid die changes, and minimal downtime, ensuring high-quality output and operational efficiency.

SMS Group's technology is widely adopted by leading extrusion press machine manufacturers and suppliers in Portugal, underpinning the industry's reputation for quality and innovation.

Technological Advancements in Extrusion Press Machines

The Portuguese extrusion press machine sector is distinguished by its embrace of technological advancements that drive efficiency, precision, and sustainability. Key innovations include:

- Hybrid Drive Technology: Modern presses utilize hybrid systems that combine the best attributes of electric and hydraulic drives, optimizing energy use and enabling precise control over extrusion parameters.

- Automated Process Control: Advanced software and sensors monitor every stage of the extrusion process, from billet heating to profile cooling, ensuring consistent quality and rapid response to any deviations.

- Rapid Tool Change Systems: Quick-change die systems minimize downtime, allowing manufacturers to switch between product lines efficiently and meet the demands of diverse markets.

- Data Analytics and Predictive Maintenance: The integration of IoT devices and data analytics platforms enables predictive maintenance, reducing unplanned outages and optimizing machine performance.

These technological advancements empower Portuguese extrusion press machine manufacturers and suppliers to offer superior products, shorter lead times, and enhanced value to their customers.

Applications and Market Segments

Extrusion press machine manufacturers and suppliers in Portugal serve a wide array of industries, each with unique requirements and specifications. The versatility of aluminum profiles produced using advanced extrusion presses makes them indispensable in the following sectors:

Construction

Aluminum profiles are extensively used in the construction industry for windows, doors, curtain walls, structural frames, and decorative elements. The ability to extrude complex shapes with tight tolerances allows architects and builders to realize innovative designs while ensuring strength and durability.

Transportation

The transportation sector benefits from lightweight aluminum profiles in automotive, railway, and commercial vehicle applications. Extruded components contribute to weight reduction, fuel efficiency, and improved safety without compromising structural integrity.

Infrastructure

Custom extrusions are essential for infrastructure projects, including bridges, tunnels, and public works. The adaptability of extrusion press machines enables the production of profiles tailored to specific engineering requirements, enhancing the longevity and performance of infrastructure assets.

Renewable Energy

The renewable energy industry relies on high-quality aluminum profiles for solar panel frames, mounting systems, and wind turbine components. Portuguese manufacturers' commitment to sustainability aligns with the green energy sector's focus on reducing carbon emissions and promoting circularity.

Electrical and Electronics

Aluminum's excellent conductivity and corrosion resistance make it ideal for electrical transmission, distribution, and electronic enclosures. Precision-extruded profiles ensure reliable performance in demanding environments.

Sustainability and Certifications

Sustainability is a defining characteristic of Portugal's extrusion press machine industry. Leading manufacturers and suppliers are committed to minimizing their environmental impact through:

- Use of Recycled Materials: The adoption of recycled aluminum billets reduces the carbon footprint of finished products and supports the circular economy.

- Energy-Efficient Production: Hybrid drive systems, heat recovery, and process optimization contribute to lower energy consumption and reduced greenhouse gas emissions.

- Environmental Certifications: Compliance with ISO 9001, CE, Qualicoat, and Alu+C- standards demonstrates a commitment to quality, safety, and environmental stewardship.

These initiatives not only enhance the reputation of Portuguese manufacturers but also appeal to environmentally conscious customers worldwide.

Market Trends and Future Outlook

As the global economy transitions towards sustainability and digitalization, the extrusion press machine industry in Portugal is poised for continued growth. Several trends are shaping the future of the market:

- Increased Automation: The adoption of robotics and smart manufacturing technologies will further improve efficiency and reduce labor costs.

- Customization and Flexibility: Manufacturers are investing in flexible production systems that can quickly adapt to changing customer requirements and market trends.

- Expansion of Export Markets: Portugal's strategic location and reputation for quality position it as a key supplier to European and international markets.

- Research and Development: Ongoing R&D efforts are focused on developing new alloys, surface treatments, and process innovations to meet evolving industry needs.

By embracing these trends, Portuguese extrusion press machine manufacturers and suppliers are well-equipped to maintain their leadership in the global market.

Conclusion

Portugal has firmly established itself as a leading center for extrusion press machine manufacturing and supply in Europe. Companies like Exlabesa, supported by technology providers such as SMS Group, exemplify the industry's commitment to quality, innovation, and sustainability. With advanced production facilities, cutting-edge technology, and a focus on environmental responsibility, Portuguese manufacturers offer reliable OEM services and customized solutions for a wide range of industries. As the demand for aluminum profiles continues to grow, Portugal's extrusion press machine sector is set to play an increasingly important role in the global supply chain.

Frequently Asked Questions (FAQs)

1. What are the main advantages of sourcing extrusion press machines from Portugal?

Portugal offers advanced manufacturing capabilities, a strategic location for European distribution, and a strong focus on sustainability. Leading manufacturers provide OEM services and high-quality profiles for various industries.

2. Which alloys can be processed by top extrusion press machine manufacturers and suppliers in Portugal?

Most leading suppliers can extrude all 6000 series aluminum alloys, including 6005, 6060, 6061, 6063, 6082, 6101, and 6106, in billets up to 8 inches.

3. How do Portuguese manufacturers ensure the sustainability of their extrusion press machines and products?

They use recycled aluminum billets, energy-efficient machinery, and maintain certifications such as ISO 9001, CE, Qualicoat, and Alu+C- to guarantee quality and environmental responsibility.

4. What technological innovations are implemented in modern extrusion press machines?

Innovations include hybrid drive systems for energy savings, automated quality control, intelligent process management, and rapid die change systems for increased productivity.

5. What is the production capacity of the largest extrusion press machine facilities in Portugal?

Exlabesa's facility in Portugal currently has a capacity of 16,000 tonnes per year, with plans to expand to over 45,000 tonnes annually, making it one of the largest in Europe.