Content Menu

● Understanding Extrusion Press Machines

>> Key Components and Working Principle

● Why Italy Excels in Extrusion Press Machine Manufacturing

>> Key Advantages of Italian Extrusion Press Machines

● Top Italian Extrusion Press Machine Manufacturers and Suppliers

>> Presezzi Extrusion S.p.A.

>> Danieli Breda

>> OMAV S.p.A.

>> Estrusione Roccafranca

>> Turla S.r.l.

>> Balconi Presseccentriche

● Detailed Company Profiles and Innovations

>> Presezzi Extrusion S.p.A. – Pioneering Sustainability and Automation

>> Danieli Breda – Integrated Solutions and Precision Engineering

>> OMAV S.p.A. – Complete Lines for Modern Production

>> Estrusione Roccafranca – High-Capacity Production

>> Turla S.r.l. – Energy Efficiency and Process Optimization

>> Balconi Presseccentriche – High-Speed Impact Extrusion

● Technological Innovations in Italian Extrusion Press Machines

>> Energy-Efficient Systems

>> Advanced Automation and Robotics

>> Rapid Die-Change Systems

>> Remote Monitoring and Data Analytics

>> Material Innovations

● Global Market Trends and Italian Leadership

>> Export Markets and International Partnerships

>> OEM and Custom Manufacturing Services

● Applications of Italian Extrusion Press Machines

● How to Choose the Right Extrusion Press Machine Manufacturer

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is an extrusion press machine?

>> 2. Why are Italian extrusion press machine manufacturers highly regarded?

>> 3. What industries use Italian extrusion press machines?

>> 4. How do Italian manufacturers ensure the quality of extrusion presses?

>> 5. What are the latest innovations in extrusion press technology?

Italy has long been recognized as a global leader in the field of extrusion press machine manufacturing, especially for aluminum and other non-ferrous metals. Italian manufacturers are renowned for their engineering excellence, technological innovation, and the ability to deliver high-performance, customized solutions to clients worldwide. This article provides an in-depth overview of the top extrusion press machine manufacturers and suppliers in Italy, exploring their advanced technologies, unique innovations, and the value they bring to international markets.

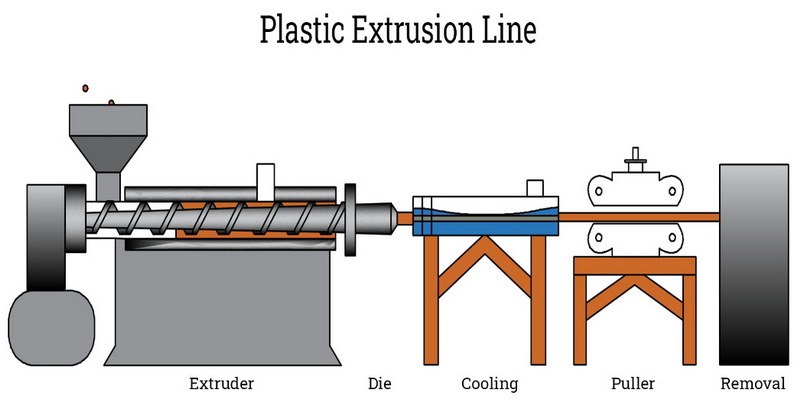

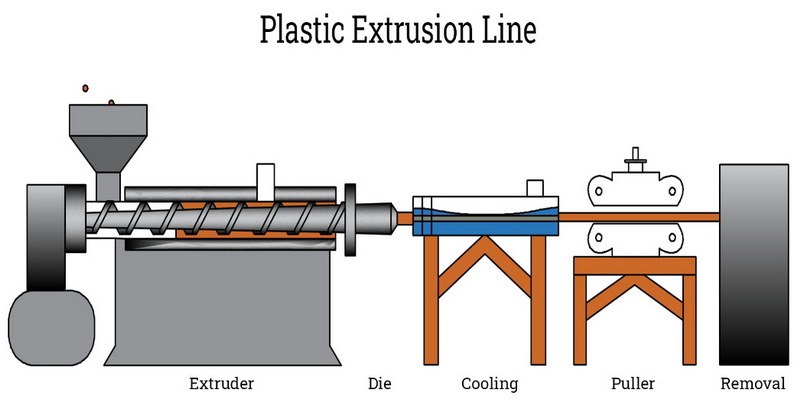

Understanding Extrusion Press Machines

Extrusion press machines are vital in shaping metals such as aluminum, copper, and brass by forcing them through a die to create complex profiles and products. These machines are widely used across industries including construction, automotive, aerospace, packaging, and consumer goods. The efficiency, precision, and reliability of the extrusion process are heavily dependent on the quality and design of the press machine used.

Key Components and Working Principle

An extrusion press machine typically consists of the following main components:

- Hydraulic or mechanical press: Provides the force needed to push the billet through the die.

- Die: The tool that shapes the material into the desired cross-section.

- Billet loader: Loads the raw material into the press.

- Heating system: Prepares the billet for extrusion by bringing it to the optimal temperature.

- Handling systems: Move the extruded product away from the press for cooling, stretching, and cutting.

The process begins with heating the metal billet, which is then loaded into the press. The press applies immense pressure, forcing the billet through the die, resulting in a continuous profile with the desired shape. The extruded product is then cooled, stretched, and cut to length.

Why Italy Excels in Extrusion Press Machine Manufacturing

Italy's dominance in the extrusion press machine sector is rooted in its rich tradition of mechanical engineering and industrial innovation. Italian manufacturers have built a reputation for producing high-quality extrusion press machines that blend advanced automation, energy efficiency, and robust construction. Their ability to customize solutions for specific client needs makes them preferred partners for OEMs, brand owners, and industrial producers worldwide.

Key Advantages of Italian Extrusion Press Machines

1. Engineering Expertise: Italian manufacturers benefit from decades of experience and a strong engineering culture.

2. Customization: They offer tailor-made solutions to address unique production requirements.

3. Innovation: Continuous investment in research and development leads to cutting-edge technologies.

4. Global Reach: Italian companies export their machines to markets all over the world, supporting a wide range of industries.

5. After-Sales Support: Comprehensive maintenance and support services ensure long-term reliability.

Top Italian Extrusion Press Machine Manufacturers and Suppliers

Presezzi Extrusion S.p.A.

Founded in 1994, Presezzi Extrusion has become a leader in the design and production of aluminum extrusion presses. The company offers a wide range of standard and custom extrusion presses, advanced automation technologies, and energy-efficient solutions. Presezzi Extrusion is known for its robust R&D efforts and commitment to sustainability, making its machines popular in automotive, construction, and industrial applications.

Danieli Breda

With over half a century of experience, Danieli Breda is recognized globally for its expertise in designing and manufacturing extrusion presses for non-ferrous metals. Danieli Breda offers a broad range of presses for aluminum, copper, and brass, focusing on maximizing productivity and product quality. The company is known for integrated plant solutions, advanced automation, closed-loop feedback control, rapid die-change systems, and remote access platforms.

OMAV S.p.A.

Established in 1952, OMAV specializes in complete aluminum extrusion lines and handling systems. The company provides full-service offerings from design to installation, robust automation, and material handling solutions. OMAV's integration with SMS Group has further enhanced its technological capabilities, with a strong focus on energy efficiency and productivity.

Estrusione Roccafranca

Part of the Extral Technology Group, Estrusione Roccafranca operates one of the largest extrusion presses in Europe. The company offers high-capacity extrusion presses for large-scale production, state-of-the-art technology, and customized solutions for specific client requirements. Estrusione Roccafranca is known for its focus on quality and ability to deliver tailored solutions for demanding applications.

Turla S.r.l.

With more than 50 years of experience, Turla manufactures complete aluminum extrusion lines with a focus on energy efficiency, quality control, and process optimization. Their machines are valued for their durability, reliability, and efficiency in continuous production environments. Turla also provides comprehensive support services, including maintenance and spare parts.

Balconi Presseccentriche

Balconi specializes in impact extrusion presses for aluminum cans, tubes, and similar products. Their presses range from 1,000 kN up to 20,000 kN, with even larger sizes available upon request. Balconi's machines are designed for high-speed production and are fully automated, making them ideal for intensive, round-the-clock operations. The company is committed to continuous improvement and technological updates.

Detailed Company Profiles and Innovations

Presezzi Extrusion S.p.A. – Pioneering Sustainability and Automation

Presezzi Extrusion's commitment to sustainability is evident in its energy-efficient press designs and the integration of advanced automation. The company's presses are equipped with smart control systems that optimize energy consumption and reduce waste. Presezzi also offers complete extrusion lines, including billet heating systems, handling equipment, and finishing machines, ensuring seamless integration and high productivity.

Danieli Breda – Integrated Solutions and Precision Engineering

Danieli Breda is known for its turnkey extrusion plants, which include not only the press itself but also upstream and downstream equipment. Their presses feature state-of-the-art hydraulic systems, rapid die-change mechanisms, and closed-loop control for precise process management. Danieli Breda's innovation extends to digital platforms that enable remote monitoring, predictive maintenance, and real-time data analysis.

OMAV S.p.A. – Complete Lines for Modern Production

OMAV's strength lies in delivering complete, automated extrusion lines. Their focus on material handling and process automation ensures smooth, efficient production flows. OMAV's partnership with SMS Group has allowed the company to develop new technologies in billet preheating, quenching, and profile handling, further enhancing the quality and consistency of extruded products.

Estrusione Roccafranca – High-Capacity Production

Estrusione Roccafranca's massive extrusion presses are capable of handling large billets and producing oversized profiles for architectural, transportation, and industrial applications. The company's expertise in automation and process control allows for high throughput without compromising on quality.

Turla S.r.l. – Energy Efficiency and Process Optimization

Turla's extrusion lines are designed for minimal energy consumption and maximum uptime. Their presses feature advanced hydraulic systems, intelligent controls, and robust construction. Turla's approach to process optimization includes comprehensive training, remote diagnostics, and ongoing technical support.

Balconi Presseccentriche – High-Speed Impact Extrusion

Balconi's impact extrusion presses are engineered for speed and accuracy, making them ideal for high-volume production of packaging materials like cans and tubes. Their automated lines ensure consistent quality and minimal downtime, while continuous innovation keeps their technology at the cutting edge.

Technological Innovations in Italian Extrusion Press Machines

Italian extrusion press machine manufacturers are at the forefront of technological advancement. Some of the most significant innovations include:

Energy-Efficient Systems

Many Italian manufacturers have adopted hybrid and electric drive systems, reducing energy consumption by up to 55%. These systems also lower operating costs and environmental impact, making them attractive to eco-conscious clients.

Advanced Automation and Robotics

Automation has become a hallmark of Italian extrusion press machines. From billet loading to profile handling and packaging, automated systems improve precision, reduce labor costs, and enhance workplace safety.

Rapid Die-Change Systems

Quick die-change mechanisms minimize downtime, allowing manufacturers to switch between products efficiently. This flexibility is essential for meeting the demands of modern, just-in-time manufacturing.

Remote Monitoring and Data Analytics

Modern extrusion presses are equipped with remote monitoring platforms and advanced data analytics tools. These features enable predictive maintenance, real-time process optimization, and better decision-making based on actionable insights.

Material Innovations

Italian manufacturers are investing in research to develop new aluminum alloys with improved properties, such as higher strength-to-weight ratios and better corrosion resistance. These materials open up new possibilities for lightweight construction and advanced engineering applications.

Global Market Trends and Italian Leadership

The global demand for aluminum and non-ferrous metal profiles is rising, driven by trends in lightweight construction, electric vehicles, and sustainable packaging. Italian extrusion press machine manufacturers are well-positioned to capitalize on these trends, thanks to their focus on innovation, quality, and customization.

Export Markets and International Partnerships

Italian manufacturers export their machines to Europe, North America, Asia, and beyond. They often collaborate with local partners to provide installation, training, and after-sales support. This global reach ensures that Italian technology is accessible to manufacturers worldwide.

OEM and Custom Manufacturing Services

Many Italian extrusion press machine manufacturers offer OEM services, working closely with international brand owners, wholesalers, and producers. These partnerships enable clients to access cutting-edge technology while maintaining their own brand identity and market presence.

Applications of Italian Extrusion Press Machines

Italian extrusion press machines are used in a wide variety of industries and applications:

- Construction: Production of window frames, curtain walls, structural beams, and architectural profiles.

- Automotive: Manufacturing of chassis components, body panels, heat exchangers, and lightweight structural parts.

- Aerospace: Production of seat tracks, fuselage components, and other lightweight, high-strength parts.

- Consumer Goods: Fabrication of furniture, appliance housings, and electronics enclosures.

- Packaging: High-speed production of aluminum cans, tubes, and bottles for food, beverage, and personal care industries.

- Renewable Energy: Creation of frames and supports for solar panels and wind turbines.

How to Choose the Right Extrusion Press Machine Manufacturer

Selecting the right extrusion press machine manufacturer or supplier in Italy is critical for ensuring long-term success and competitiveness. Consider the following factors:

- Experience and Reputation: Choose companies with a proven track record and positive references from global clients.

- Customization Capabilities: Ensure the manufacturer can tailor solutions to your specific production requirements.

- After-Sales Support: Look for comprehensive support, maintenance, and spare parts availability.

- Technological Innovation: Select manufacturers that invest in R&D and offer the latest advancements.

- Energy Efficiency: Modern presses should incorporate energy-saving features to reduce operational costs.

- Integration and Automation: Advanced automation and seamless integration with other production systems can significantly boost efficiency.

Conclusion

Italy's extrusion press machine manufacturers and suppliers are at the forefront of global innovation, offering reliable, efficient, and technologically advanced solutions for a wide range of industries. Companies like Presezzi Extrusion, Danieli Breda, OMAV, Estrusione Roccafranca, Turla, and Balconi continue to set industry standards through ongoing research, customization, and a commitment to quality. Their machines enable manufacturers worldwide to achieve higher productivity, lower operational costs, and superior product quality.

Frequently Asked Questions (FAQ)

1. What is an extrusion press machine?

An extrusion press machine is a device that shapes metals, such as aluminum, by forcing them through a die to create profiles with specific cross-sections. This process is widely used in manufacturing for its ability to produce complex shapes efficiently.

2. Why are Italian extrusion press machine manufacturers highly regarded?

Italian manufacturers are known for their engineering expertise, innovation, and ability to deliver high-quality, customized solutions. Their presses incorporate advanced automation, energy efficiency, and robust construction, making them leaders in the global market.

3. What industries use Italian extrusion press machines?

Industries such as construction, automotive, aerospace, packaging, and consumer goods rely on Italian extrusion press machines for producing structural components, profiles, packaging materials, and more.

4. How do Italian manufacturers ensure the quality of extrusion presses?

Quality is maintained through rigorous design standards, advanced automation, closed-loop control systems, and comprehensive testing. Many manufacturers also offer remote monitoring and predictive maintenance services.

5. What are the latest innovations in extrusion press technology?

Recent innovations include hybrid and electric drive systems for energy savings, rapid die-change mechanisms, advanced automation, and remote data analytics for process optimization.