Content Menu

● The Importance of Extrusion Press Machines in Modern Industry

● Overview of the American Extrusion Press Market

● Top Extrusion Press Machine Manufacturers and Suppliers in America

>> 1. SMS Group

>> 2. Macrodyne Technologies

>> 3. Ajax/CECO/Erie Press

>> 4. Butech Bliss

>> 5. Presezzi Extrusion North America

>> 6. Beckwood Press

>> 7. Other Notable Suppliers

>> 8. Top Aluminum Extrusion Companies (End Users)

● Key Technologies and Innovations in Extrusion Press Machinery

● How to Choose the Right Extrusion Press Machine Supplier

● Maintenance and Troubleshooting of Extrusion Press Machines

● Market Trends and Future Outlook

● Conclusion

● Frequently Asked Questions

>> 1. What is the most common issue in extrusion press machines?

>> 2. How often should maintenance be performed on extrusion press machines?

>> 3. What are the key factors affecting the extrusion process?

>> 4. How do hybrid drive systems improve extrusion press performance?

>> 5. What industries rely most on extrusion press machine manufacturers and suppliers?

In today's fast-paced manufacturing landscape, extrusion press machines have become the backbone of modern industry. These machines are essential for producing high-quality, high-precision metal and plastic profiles used across a wide range of sectors, including automotive, aerospace, construction, and electronics. As the demand for lightweight, durable, and customizable materials continues to grow, the need for reliable extrusion press machine manufacturers and suppliers—especially those offering OEM services—has never been greater.

This comprehensive guide explores the leading extrusion press machine manufacturers and suppliers in America, their technological advancements, the latest market trends, and the key factors to consider when selecting a partner for your extrusion needs. Whether you are a brand owner, wholesaler, or manufacturer seeking OEM solutions, understanding the landscape of extrusion press machine suppliers will empower your business to make informed decisions and maintain a competitive edge.

The Importance of Extrusion Press Machines in Modern Industry

Extrusion press machines play a pivotal role in shaping raw materials into finished products with precise cross-sectional profiles. The process involves forcing a heated billet or slug of material—typically aluminum, steel, or plastic—through a die to create long, continuous shapes such as rods, tubes, and custom profiles. The resulting products are essential in:

- Automotive manufacturing: lightweight frames, structural components, and body panels

- Aerospace engineering: precision parts, fuselage elements, and heat exchangers

- Construction: window frames, curtain walls, support beams, and railings

- Electronics: heat sinks, enclosures, and connectors

- Consumer goods: furniture, appliances, and sporting equipment

The efficiency, repeatability, and versatility of extrusion press machines make them indispensable for both mass production and custom fabrication, enabling manufacturers to meet the ever-changing demands of the global market.

Overview of the American Extrusion Press Market

The United States is a global leader in the production and consumption of extruded products, particularly aluminum extrusions. Despite challenges posed by economic fluctuations and global events, the North American extrusion market remains robust and innovative. The market size was valued at over USD 12.3 billion in 2019 and is projected to reach USD 21 billion by 2029, reflecting strong and sustained growth.

Key Market Drivers:

- Expanding automotive, aerospace, and construction industries

- Increasing demand for lightweight, high-strength materials

- Technological advancements in press machinery and automation

- Government initiatives supporting industrial development and sustainability

Market Characteristics:

- Over 125 extruders in North America, operating nearly 500 presses at almost 200 locations

- A diverse range of manufacturers, from specialized OEMs to global technology leaders

- Strong focus on energy efficiency, automation, and customization to meet specific industry needs

Top Extrusion Press Machine Manufacturers and Suppliers in America

Below is a curated list of the most reputable extrusion press machine manufacturers and suppliers in America, each recognized for their innovation, quality, and industry expertise.

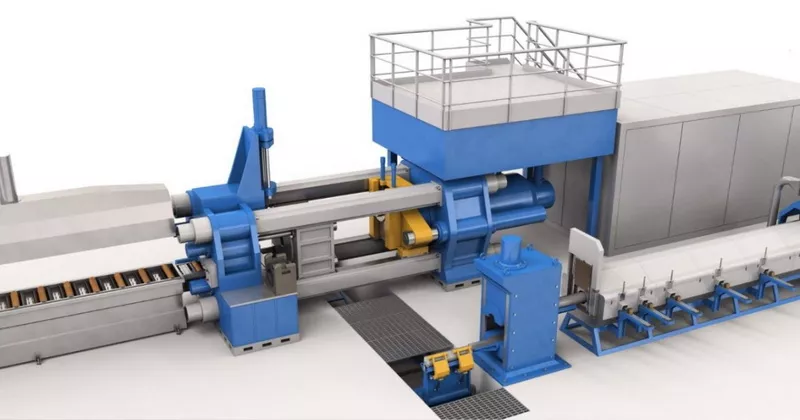

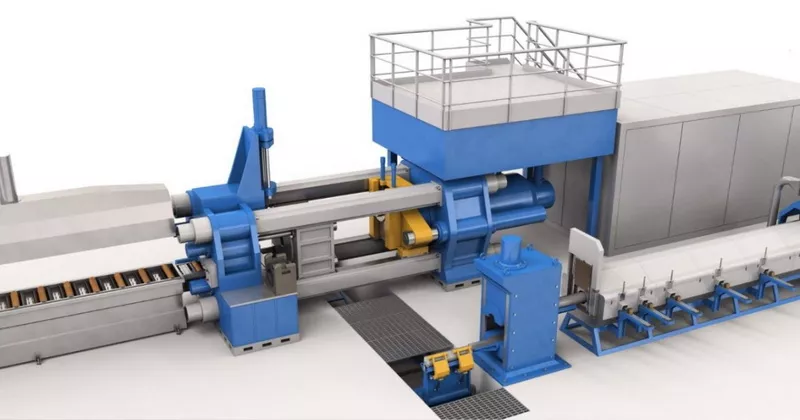

1. SMS Group

SMS Group is a global leader in light metal extrusion presses, offering advanced solutions such as short-stroke, front-loader extrusion presses with FEM-optimized frames. Their HybrEx® series features hybrid drive systems that reduce energy consumption by up to 55% and increase productivity by up to 20%. SMS Group's presses are renowned for their precision, durability, and ease of integration into automated production lines.

Key Features:

- Hybrid drive technology (electric servomotors combined with hydraulics)

- High rigidity and long service life

- Full range of auxiliary and outlet devices

- Eco-friendly solutions with reduced energy consumption

2. Macrodyne Technologies

Macrodyne is a leading manufacturer of hydraulic extrusion and vertical presses for both hot and cold extrusion applications. They offer custom design and build capabilities, ensuring each press is tailored to the client's specific requirements. Macrodyne's partnership with Belco Industries allows them to provide full turnkey extrusion press lines ranging from 500 to 8,000 tons.

Key Features:

- Custom hydraulic and vertical presses

- Hot and cold extrusion for ferrous and non-ferrous materials

- Standalone or fully automated press line configurations

- Local technical service and modernization options

3. Ajax/CECO/Erie Press

Ajax Erie is a pioneer in carbon extrusion technology, manufacturing high-quality carbon extrusion presses for diverse industries. Their presses are known for strength, precision, and efficiency, catering to automotive, aerospace, and construction sectors. Ajax Erie offers custom solutions, leveraging over a century of engineering expertise.

Key Features:

- Custom carbon extrusion presses

- High efficiency and precision

- Advanced engineering and innovation

- Comprehensive support and upgrades

4. Butech Bliss

Butech Bliss is recognized for its advanced engineering in extrusion press and forging equipment. They provide both new presses and repair/upgrade services, ensuring maximum productivity and longevity for their clients' operations.

Key Features:

- Advanced engineering and analysis

- Custom consulting and troubleshooting

- Repair and upgrade services

- Industry-leading field engineers

5. Presezzi Extrusion North America

Part of the Presezzi Group, this company offers complete extrusion lines for aluminum, copper, brass, steel, and hard alloys. Their solutions include not only extrusion presses but also remelt plants and automation systems, making them a one-stop shop for extrusion needs.

Key Features:

- Complete extrusion lines for multiple materials

- Integration with automation and remelt systems

- High-quality equipment and global expertise

6. Beckwood Press

Beckwood Press specializes in custom aluminum extrusion presses, serving industries such as aerospace, automotive, construction, and defense. Their presses are known for robust construction and advanced automation features.

Key Features:

- Customizable bolster dimensions and stroke

- Automated and multi-ram configurations

- Broad industry coverage

7. Other Notable Suppliers

- Savage Hydraulic Presses: Standard and custom hydraulic extrusion presses (50 to 2,500 tons)

- Trinks Inc.: Hydraulic lithium extrusion presses with advanced vacuum and process controls

- Danieli: Extrusion presses for non-ferrous, steel, titanium, and graphite materials

- Hydramet American, Inc.: Custom hydraulic extrusion presses

8. Top Aluminum Extrusion Companies (End Users)

While not all are press manufacturers, these companies operate some of the largest and most advanced extrusion presses in the U.S., and often collaborate closely with machine suppliers:

| Company | City | State | Sales ($) |

| Bonnell Aluminium | Newnan | GA | 250 mil+ |

| Custom Aluminium Products | South Elgin | IL | 250 mil+ |

| Sierra Aluminium | Riverside | CA | 250 mil+ |

| Astro Shapes | Struthers | OH | 100-250 mil+ |

| Taber Extrusions | Gulfport | MS | 100-250 mil+ |

| Vitex Extrusions | Franklin | NH | 50-100 mil+ |

| Pennex Aluminium | Wellsville | PA | 25-50 mil+ |

| Western Extrusions | Carrolton | TX | 10-25 mil+ |

| Aluminium Shapes | Delair | NJ | - |

Key Technologies and Innovations in Extrusion Press Machinery

Modern extrusion press machines are defined by their technological sophistication, energy efficiency, and adaptability. Leading manufacturers invest heavily in R&D to deliver machines that meet the evolving demands of industry.

Notable Innovations:

- Hybrid Drive Systems: Combining electric servomotors with hydraulic systems for greater efficiency and precision.

- Short-Stroke, Front-Loader Designs: Allow for compact, rigid systems with fast cycle times and improved profile quality.

- Automated Die Change Systems: Reduce downtime and enable rapid switching between profiles.

- Advanced Process Controls: Real-time monitoring and adjustment of temperature, pressure, and speed for optimal results.

- Energy-Efficient Heating: Use of induction and gas-fired continuous furnaces with heat recovery systems for billet preparation.

- Integrated Quenching and Cooling: Ensures consistent mechanical properties and reduces residual stresses in extruded profiles.

- Data Analytics and IoT Integration: Many modern presses are equipped with sensors and software that allow for predictive maintenance, real-time monitoring, and process optimization. This not only reduces downtime but also ensures higher product quality and traceability.

How to Choose the Right Extrusion Press Machine Supplier

Selecting the right extrusion press machine manufacturer or supplier is crucial for ensuring long-term productivity, product quality, and operational efficiency. Consider the following factors:

- Technical Expertise: Does the supplier have a proven track record in your industry and with your required materials?

- Customization Capabilities: Can they design and build presses tailored to your specific needs?

- Service and Support: Do they offer local technical support, spare parts, and modernization services?

- Automation and Integration: Are their machines compatible with your existing production lines and automation systems?

- Energy Efficiency: Does the equipment meet modern standards for energy consumption and environmental impact?

- References and Reputation: What do other customers in your industry say about their reliability and service?

- After-Sales Service: Reliable after-sales service, including maintenance, troubleshooting, and access to spare parts, is essential for minimizing downtime and protecting your investment.

- Compliance and Certifications: Ensure the supplier's machines comply with relevant industry standards and certifications, which can affect product quality and marketability.

Maintenance and Troubleshooting of Extrusion Press Machines

Proper maintenance is essential for maximizing the lifespan and performance of extrusion press machines. Common issues include die wear, hydraulic system failures, overheating, and alignment problems. Regular preventive maintenance, operator training, and adherence to manufacturer guidelines can minimize downtime and costly repairs.

Best Practices for Maintenance:

- Routine Inspections: Schedule regular inspections of critical components, including dies, hydraulic systems, and electrical controls.

- Lubrication: Ensure all moving parts are properly lubricated to reduce wear and prevent overheating.

- Alignment Checks: Regularly check the alignment of the press and dies to ensure consistent product quality.

- Hydraulic System Maintenance: Monitor fluid levels and replace hydraulic fluids as recommended by the manufacturer.

- Operator Training: Provide ongoing training for operators to ensure safe and efficient machine operation.

- Spare Parts Inventory: Keep an inventory of essential spare parts to minimize downtime during repairs.

Market Trends and Future Outlook

The extrusion press machine market in America is poised for continued growth, driven by several key trends:

- Increased Demand for Lightweight Materials: The push for fuel efficiency in automotive and aerospace sectors is driving demand for aluminum and other lightweight extrusions.

- Sustainability Initiatives: Manufacturers are focusing on eco-friendly processes, including energy-efficient presses and recycling of scrap materials.

- Digital Transformation: The integration of Industry 4.0 technologies, such as IoT and data analytics, is enabling smarter, more connected extrusion operations.

- Customization and Flexibility: As markets become more competitive, the ability to quickly switch between products and customize profiles is becoming a major differentiator.

- Globalization and Supply Chain Optimization: American manufacturers are increasingly partnering with international suppliers and OEMs to optimize costs and access new technologies.

Conclusion

America's extrusion press machine manufacturers and suppliers are at the forefront of industrial innovation, offering a wide array of solutions for diverse applications. From global technology leaders like SMS Group and Macrodyne to specialized providers such as Ajax Erie and Butech Bliss, the market is rich with expertise and advanced machinery. By understanding the strengths of each supplier and the latest technological trends, businesses can confidently select partners that will drive their success in a competitive global marketplace.

Frequently Asked Questions

1. What is the most common issue in extrusion press machines?

The most frequent issues include die wear, hydraulic system failures, and overheating. Regular maintenance and adherence to operational guidelines can minimize these problems.

2. How often should maintenance be performed on extrusion press machines?

Preventive maintenance should be conducted monthly, with major inspections every six months or as recommended by the machine manufacturer.

3. What are the key factors affecting the extrusion process?

Critical factors include die design, extrusion ratio, billet temperature, lubrication, extrusion speed, and the properties of the metal being extruded.

4. How do hybrid drive systems improve extrusion press performance?

Hybrid drive systems use electric servomotors for efficiency and precision, with hydraulic systems providing high force where needed. This reduces energy consumption and increases productivity.

5. What industries rely most on extrusion press machine manufacturers and suppliers?

Key industries include automotive, aerospace, construction, electronics, and consumer goods, all of which require high-precision, custom extruded profiles.