Content Menu

● Understanding Automatic Extrusion Lines and Their Importance

>> What Are Automatic Extrusion Lines?

>> Industries Benefiting from Automatic Extrusion Line Manufacturers And Suppliers in Australia

● Advantages of Partnering with Australian Automatic Extrusion Line Manufacturers And Suppliers

>> 1. Cutting-Edge Technology and Automation

>> 2. Comprehensive Quality Assurance

>> 3. Customized OEM Capabilities

>> 4. Commitment to Sustainability

● Leading Automatic Extrusion Line Manufacturers And Suppliers in Australia

>> 1. Capral Aluminium

>> 2. Ullrich Aluminium

>> 3. G.James Group

>> 4. INEX Metals

>> 5. Aluminium Industries

● Technological Trends and Innovations in Australia's Extrusion Sector

>> Industry 4.0 and Digitalization

>> Smart Robotics and Automation

>> Advanced Die and Alloy Development

● How to Choose the Right Automatic Extrusion Line Manufacturer And Supplier

● Benefits of Integrating Chinese OEM Automatic Extrusion Line Factories

● Best Practices for Maximizing Value From Automatic Extrusion Line Suppliers

● The Future Outlook for Automatic Extrusion Line Manufacturers And Suppliers in Australia

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of using automated extrusion lines?

>> 2. How do I choose the right automatic extrusion line supplier for my business?

>> 3. Can Australian manufacturers export custom extrusion lines overseas?

>> 4. How important are quality certifications for extrusion line suppliers?

>> 5. What technical support can I expect from a top automatic extrusion line manufacturer?

Automatic extrusion lines play a crucial role in modern manufacturing by enabling the high-efficiency production of aluminum, plastics, and composite profiles crucial to various industrial sectors. Australia, with its growing infrastructure, renewable energy initiatives, and manufacturing sophistication, has witnessed an increasing demand for advanced extrusion solutions. Local manufacturers and suppliers specializing in automatic extrusion lines are expanding capabilities to meet diverse needs—ranging from large-scale construction projects to precise OEM requirements for international brand owners.

This article provides an in-depth exploration of the top automatic extrusion line manufacturers and suppliers in Australia. It covers their technological strengths, the industries they serve, factors to consider when selecting a partner, and the benefits of OEM collaborations. Additionally, the article analyzes market trends, sustainability efforts, and future innovations that define Australia's extrusion landscape.

Understanding Automatic Extrusion Lines and Their Importance

What Are Automatic Extrusion Lines?

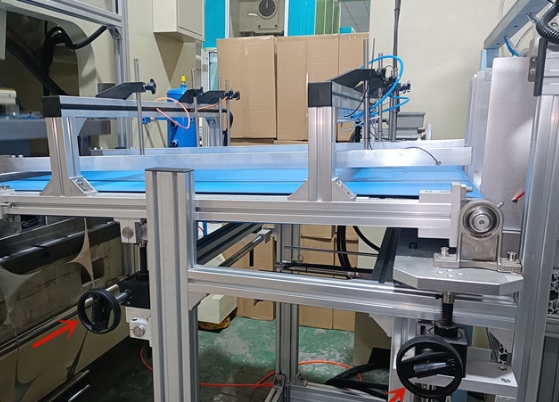

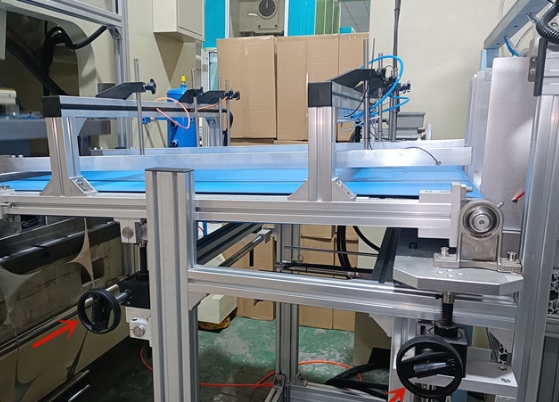

Automatic extrusion lines refer to highly automated production systems designed to create continuous lengths of specific cross-sectional profiles from raw materials, such as aluminum alloys or plastics. These lines integrate various stages such as billet heating, extrusion pressing, cooling, cutting, and packaging—all orchestrated with minimal manual intervention via robotics and computer control systems.

The main purpose of these automated lines is to increase production speed, improve dimensional accuracy, reduce waste, and offer consistent quality, which is essential for meeting the demands of sophisticated industries with strict tolerance and performance requirements.

Industries Benefiting from Automatic Extrusion Line Manufacturers And Suppliers in Australia

Extrusion technology is indispensable to a wide range of Australian industries, including but not limited to:

- Construction and Infrastructure: Automatic extrusion lines produce window and door frames, curtain walls, structural beams, and architectural facades.

- Transportation and Automotive: Vehicles, rail cars, and marine vessels rely on aluminum extrusions for lightweight structural components.

- Renewable Energy: Frames for solar panels and wind turbine components benefit from precision-engineered extrusions.

- Consumer Goods: Sporting equipment, furniture components, and household frameworks utilize aluminum extrusions for durability and design versatility.

- Mining and Heavy Equipment: Mining machinery and heavy vehicle parts are manufactured using specialized extrusion profiles catering to tough operating environments.

Advantages of Partnering with Australian Automatic Extrusion Line Manufacturers And Suppliers

1. Cutting-Edge Technology and Automation

Australia's leading suppliers invest heavily in adopting the latest advances in Industry 4.0, including sensor-based real-time monitoring, robotics, and AI-powered analytics. These technologies enhance product quality, reduce energy consumption, and boost throughput — critical factors in today's competitive manufacturing environments.

2. Comprehensive Quality Assurance

Suppliers maintain strict adherence to international standards such as ISO 9001 and ASTM, ensuring the reliability of extrusion lines and the profiles they produce. Automatic inspection equipment embedded within extrusion lines performs continuous dimensional checks, reducing defects and increasing end-user confidence.

3. Customized OEM Capabilities

Many Australian extrusion line manufacturers offer customizable equipment and OEM services tailored to client specifications. This encompasses adapting extrusion speeds, dies, tooling setups, and downstream handling systems. International brands and distributors benefit from seamless supply chain integration and proprietary solutions that preserve brand integrity.

4. Commitment to Sustainability

Australian manufacturers prioritize environmentally sustainable practices. This commitment includes energy-efficient machinery, waste recycling programs, use of recycled raw materials, and compliance with stringent environmental regulations. Such sustainable operations appeal especially to global companies with green procurement mandates.

Leading Automatic Extrusion Line Manufacturers And Suppliers in Australia

1. Capral Aluminium

Capral Aluminium stands as a dominant figure in Australia's extrusion market with its high-capacity and technologically advanced automatic extrusion lines. Their expertise lies in custom profile development and integrated finishing services—including anodizing and powder coating—making them a preferred supplier across construction, transport, and industrial sectors.

2. Ullrich Aluminium

Ullrich Aluminium combines strong automation with profound technical know-how to deliver precision extrusions suited for both local and export clientele. Its automated product handling and packaging systems ensure efficient turnaround and quality consistency, crucial for the construction, solar, and defense industries.

3. G.James Group

G.James Group is a vertically integrated manufacturer that not only produces extrusion profiles but also offers fabrication and glazing solutions. Their state-of-the-art extrusion lines incorporate CAD/CAM design tools for die optimization and offer complete OEM support including assembly and logistics, primarily serving sectors like high-rise construction and transport infrastructure.

4. INEX Metals

Known for adhering to the highest European and international standards, INEX Metals caters to industries like mining, transportation, and building. Their integrated automatic extrusion lines include rapid prototyping capabilities and a broad range of alloys, delivering customized solutions tailored to exacting OEM standards.

5. Aluminium Industries

Aluminium Industries, a flexible service provider, handles both bulk and short-run extrusion orders, emphasizing continuous process improvement. Their modern extrusion lines with automated handling and assembly options innovate product development, addressing consumer goods, renewable energy, and industrial supply chains.

Technological Trends and Innovations in Australia's Extrusion Sector

Industry 4.0 and Digitalization

Digitalization plays a transformative role within Australian extrusion lines. Embedded sensors collect real-time data on temperatures, pressures, extrusion force, and product dimensions. Advanced software platforms analyze this data to flag faults instantly and trigger predictive maintenance schedules that minimize costly downtime.

The advent of digital twins—virtual replicas of extrusion equipment—allows operators to simulate production runs, optimize settings, and implement improvements without interrupting actual production. These technologies guarantee greater reliability, efficiency, and product quality.

Smart Robotics and Automation

Automated robotic systems facilitate billet loading, extrusion, cutting, and packaging, reducing labor costs and safety risks. Robotics also ensure exact repeatability in handling complex shapes and large volumes—enabling manufacturers to meet higher customer expectations faster.

Advanced Die and Alloy Development

Cutting-edge CAD/CAM tools enhance die design and reduce changeover times. Material science developments usher in stronger, lighter aluminum alloys with improved corrosion resistance, supporting advanced applications in aerospace, defense, and sustainable energy markets.

How to Choose the Right Automatic Extrusion Line Manufacturer And Supplier

When selecting an automatic extrusion line supplier, consider these essential criteria:

- Production Volume and Flexibility: Ensure the supplier can scale from prototype to mass production while accommodating future product variations.

- Quality Assurance Measures: Review certifications, quality control systems, and inspection capabilities to guarantee product consistency.

- Technical and After-Sales Support: Confirm the availability of comprehensive operator training, maintenance services, and quick technical assistance.

- OEM Expertise: For brand owners requiring customized or private label machinery, the supplier's OEM experience and confidentiality should be verified.

- Sustainability Initiatives: Preference should be given to partners with proven commitments to environmentally sound manufacturing.

Benefits of Integrating Chinese OEM Automatic Extrusion Line Factories

While Australian manufacturers provide high-quality, advanced solutions, partnering with Chinese OEM factories offers additional advantages for global brands:

- Competitive pricing structures and faster delivery lead times.

- Extensive customization aligning with branding and process needs.

- Collaborative R&D opportunities leveraging global extrusion technology advances.

- Diverse supply chain options that enhance resilience.

International clients should conduct thorough due diligence on certifications, export experience, and references to maintain quality and delivery performance.

Best Practices for Maximizing Value From Automatic Extrusion Line Suppliers

- Articulate detailed technical requirements and production forecasts upfront.

- Request references or case studies showcasing relevant industrial experience.

- Confirm the integration of green technologies in manufacturing.

- Secure clear OEM agreements protecting intellectual property and proprietary designs.

The Future Outlook for Automatic Extrusion Line Manufacturers And Suppliers in Australia

Australia's extrusion industry is poised for continued growth and innovation. Key forthcoming developments include:

- Expanded deployment of AI and machine learning for autonomous process optimization.

- Increased use of recycled aluminum and renewable energy powering extrusion lines.

- Development of hybrid composite extrusion technologies combining metals with polymers.

- Broader adoption of digital supply chain management supporting flexible, just-in-time manufacturing.

These trends position Australian manufacturers and their global partners at the forefront of extrusion technology innovation, supporting industries worldwide with efficient, high-quality solutions.

Conclusion

In summary, Australian automatic extrusion line manufacturers and suppliers are integral to the nation's manufacturing infrastructure and export economy. Combining advanced automation, rigorous quality practices, customization capabilities, and sustainability efforts, these companies cater effectively to demanding industries such as construction, transportation, renewable energy, and consumer goods. By leveraging cutting-edge technology and embracing OEM collaboration, they empower global brands and wholesalers to meet evolving market requirements efficiently.

For international companies seeking extrusion line partners, Australia offers a suite of experienced manufacturers committed to precision, reliability, and innovation. When complemented by strategic partnerships with competitive Chinese OEM factories, global supply chains become more resilient and versatile. As Industry 4.0 and environmental standards continue to raise the bar, Australian extrusion suppliers remain well-positioned to lead the sector into the future.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using automated extrusion lines?

Automated extrusion lines provide increased production speed, uniform product quality, reduced labor costs, enhanced safety, and the ability to handle both large-scale and highly customized manufacturing requirements efficiently.

2. How do I choose the right automatic extrusion line supplier for my business?

You should assess the supplier's production capacity, technological sophistication, quality certifications, after-sales service capabilities, and experience with OEM customizations relevant to your industry.

3. Can Australian manufacturers export custom extrusion lines overseas?

Yes, many Australian manufacturers provide customized automatic extrusion lines tailored to international clients' specifications, including OEM branding and comprehensive technical documentation.

4. How important are quality certifications for extrusion line suppliers?

Quality certifications like ISO 9001 demonstrate adherence to international manufacturing standards and are essential for ensuring consistent product quality and securing global OEM partnerships.

5. What technical support can I expect from a top automatic extrusion line manufacturer?

Leading suppliers typically offer full commissioning support, operator training, preventive maintenance schedules, troubleshooting assistance, and upgrade options to optimize extrusion line performance throughout its lifecycle.