Content Menu

● Introduction to Aluminum Extrusion Presses

● Leading Aluminum Extrusion Press Manufacturers and Suppliers in Switzerland

>> Alu Menziken

>> Kanya AG

>> Constellium

>> Other Notable Swiss Suppliers

● The Aluminum Extrusion Process Explained

>> Step-by-Step Process

>> Continuous Improvement

● Key Criteria for Selecting an Aluminum Extrusion Press Manufacturer

● Applications of Swiss Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What makes Swiss aluminum extrusion press manufacturers and suppliers stand out internationally?

>> 2. How do I select the best aluminum extrusion press manufacturer for my project?

>> 3. What types of aluminum alloys do Swiss manufacturers commonly use?

>> 4. Can Swiss suppliers provide finished, ready-to-install aluminum components?

>> 5. What is the typical lead time for aluminum extrusions from Swiss manufacturers?

Switzerland is globally recognized for its engineering prowess and commitment to quality manufacturing. The country's aluminum extrusion press manufacturers and suppliers are no exception, standing at the forefront of innovation and precision. Whether you are an OEM, a wholesaler, or a production company, understanding the Swiss aluminum extrusion landscape is crucial for sourcing reliable, high-performance solutions. This comprehensive guide explores the leading aluminum extrusion press manufacturers and suppliers in Switzerland, delves into the extrusion process, outlines essential selection criteria, and provides actionable insights for international buyers.

Introduction to Aluminum Extrusion Presses

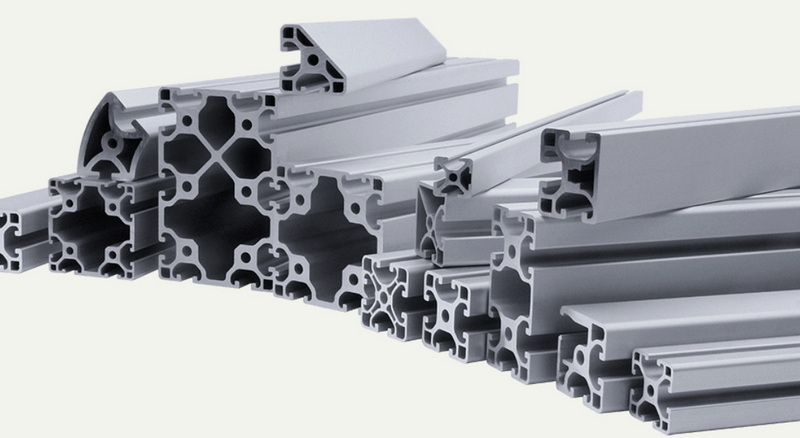

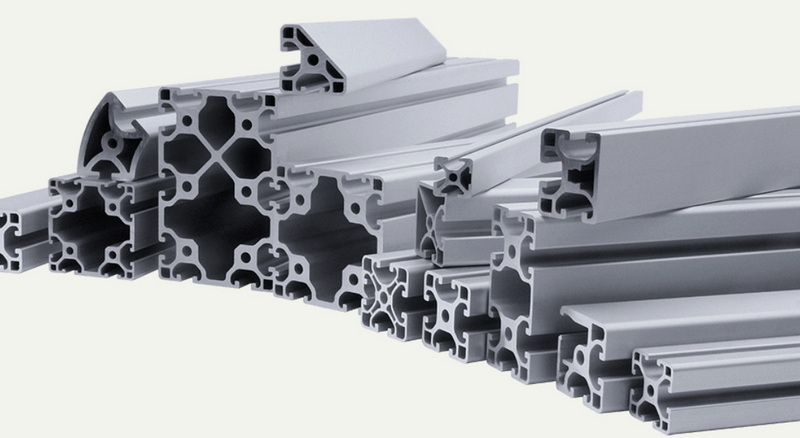

Aluminum extrusion presses are sophisticated machines that transform raw aluminum billets into complex, high-strength profiles by forcing the heated metal through a custom-designed die. The resulting extrusions are used across a wide spectrum of industries due to aluminum's unique combination of lightness, durability, corrosion resistance, and design flexibility. Swiss aluminum extrusion press manufacturers and suppliers have built a reputation for delivering consistent quality, advanced technology, and customized solutions to clients worldwide.

Leading Aluminum Extrusion Press Manufacturers and Suppliers in Switzerland

Switzerland's aluminum extrusion industry is shaped by a deep-rooted culture of precision engineering and a relentless pursuit of innovation. The following companies represent the pinnacle of Swiss expertise in aluminum extrusion press manufacturing and supply.

Alu Menziken

Overview:

Alu Menziken is a flagship name among aluminum extrusion press manufacturers and suppliers in Switzerland. With decades of experience and a focus on advanced technology, the company serves demanding sectors such as automotive, aerospace, railway, pneumatic, construction, and industrial manufacturing.

Capabilities and Features:

- Operates five extrusion presses with press forces ranging from 11 to 60 MN, enabling the production of both small and large profiles.

- Processes a wide range of aluminum alloys, including 3xxx, 4xxx, 5xxx, 6xxx, and 7xxx series, suitable for diverse applications.

- Annual production capacity of approximately 30,000 metric tons.

- Can manufacture profiles with wrap options from 10 mm to 420 mm and profile weights from 0.1 kg/m to 30 kg/m.

- Offers comprehensive services: mechanical processing, surface finishing, heat treatment, and the assembly of ready-to-install components.

- Maintains rigorous quality assurance protocols, including in-house testing and certification.

Alu Menziken's commitment to research and development ensures continuous improvement in product performance and manufacturing efficiency. Their ability to handle complex, custom projects makes them a preferred partner for international clients seeking OEM aluminum extrusion solutions.

Kanya AG

Overview:

Kanya AG is a global leader in modular aluminum extrusion systems, renowned for its Swiss quality and innovative engineering. The company supplies aluminum profiles and components for custom machine building, automation, and industrial construction.

Capabilities and Features:

- Headquarters in Rüti ZH, Switzerland, with a team of over 50 skilled professionals.

- Provides cut-to-measure, processed, and fully assembled aluminum extrusions, ready for immediate integration into client projects.

- Maintains a worldwide network of over 20 partners, ensuring fast delivery and local support for international customers.

- Offers expert consultation, design assistance, and execution of both simple and highly complex construction solutions.

- Focuses on modularity and flexibility, allowing customers to easily adapt and expand their systems.

Kanya AG's dedication to customer satisfaction, combined with its technical expertise, positions it as a top choice among aluminum extrusion press manufacturers and suppliers for clients seeking tailored, high-quality solutions.

Constellium

Overview:

Constellium is a major aluminum extrusion press manufacturer and supplier with a strong presence in Switzerland and across Europe. The company specializes in the development and production of customized extrusions, tubes, and bars in both soft and hard aluminum alloys.

Capabilities and Features:

- Serves key markets such as automotive, transport, industrial, energy, and building and construction.

- Offers advanced downstream services, including machining, surface treatment, and assembly.

- Invests heavily in research and development, resulting in innovative products that meet the evolving needs of global industries.

- Provides comprehensive technical support and project management for complex, large-scale orders.

Constellium's global reach and commitment to sustainability make it an attractive partner for clients seeking environmentally responsible aluminum extrusion solutions.

Other Notable Swiss Suppliers

Beyond the industry leaders, Switzerland is home to a dynamic network of smaller, specialized aluminum extrusion press manufacturers and suppliers. These companies often focus on niche markets, custom profiles, and rapid prototyping, offering valuable flexibility and responsiveness to international buyers. Many Swiss suppliers have extensive experience in providing OEM services, making them ideal partners for foreign brands, wholesalers, and production companies looking to outsource aluminum extrusion manufacturing.

The Aluminum Extrusion Process Explained

A clear understanding of the aluminum extrusion process is essential for anyone sourcing from aluminum extrusion press manufacturers and suppliers. The process is both art and science, requiring precise control at every stage to ensure the highest quality profiles.

Step-by-Step Process

1. Die Preparation:

The extrusion die, typically made from hardened steel, is preheated to between 450°C and 500°C. This step ensures even metal flow, reduces wear, and extends the die's lifespan.

2. Billet Preheating:

Aluminum billets are heated to a temperature of 400°C to 500°C, making them malleable enough for extrusion without melting.

3. Billet Loading and Lubrication:

The preheated billet is lubricated to prevent sticking and then loaded into the extrusion press.

4. Extrusion:

A powerful hydraulic ram applies immense pressure (often up to 25,000 tons) to force the billet through the die. The aluminum takes on the shape of the die opening, forming a continuous profile.

5. Quenching:

As the extruded profile exits the die, it is rapidly cooled using air or water to lock in its mechanical properties and prevent warping.

6. Shearing and Cooling:

The extrusion is cut to length and allowed to cool further to room temperature.

7. Stretching and Straightening:

The profiles are stretched to correct any twisting and ensure perfect alignment, which is critical for maintaining tight tolerances.

8. Cutting, Machining, and Finishing:

Final cutting, precision machining, and surface finishing (such as anodizing or powder coating) are performed according to customer specifications.

9. Inspection and Quality Control:

Rigorous quality checks, including dimensional inspection, mechanical testing, and surface evaluation, ensure that each profile meets the required standards.

Continuous Improvement

Swiss aluminum extrusion press manufacturers and suppliers are known for their commitment to continuous process improvement. They invest in automation, digital monitoring, and data analytics to optimize efficiency, reduce waste, and guarantee consistent product quality.

Key Criteria for Selecting an Aluminum Extrusion Press Manufacturer

Selecting the right aluminum extrusion press manufacturer or supplier is a critical decision that can impact your project's success. Here are the key factors to consider:

- Technical Capability:

Evaluate the manufacturer's machinery, die design expertise, and ability to work with the specific alloys and profile tolerances your project requires.

- Quality Assurance:

Look for ISO 9001 certification and a proven track record of quality control. Reliable manufacturers will have robust inspection protocols and transparent documentation.

- Customization and Flexibility:

The ability to handle custom profiles, rapid prototyping, and small-batch production is essential for many OEM and specialty projects.

- Production Capacity and Lead Time:

Assess the supplier's ability to meet your volume needs and deliver on time, especially for large or recurring orders.

- Customer Service and Support:

Choose a supplier with responsive communication, technical support, and a willingness to collaborate on design and process optimization.

- Post-Processing and Value-Added Services:

Integrated services such as machining, surface finishing, assembly, and packaging can streamline your supply chain and reduce costs.

- Sustainability and Compliance:

Swiss manufacturers are increasingly focused on sustainable practices, including recycling, energy efficiency, and compliance with international environmental standards.

- Global Reach and Logistics:

For international buyers, a supplier's ability to manage global logistics, provide export documentation, and support overseas delivery is vital.

Applications of Swiss Aluminum Extrusions

Swiss aluminum extrusion press manufacturers and suppliers cater to a diverse range of industries, reflecting the versatility of aluminum extrusions. Key application areas include:

- Automotive:

Lightweight structural components, crash management systems, battery housings, and decorative trims.

- Aerospace:

High-strength, precision extrusions for aircraft frames, seat tracks, and interior fittings.

- Construction:

Profiles for windows, doors, curtain walls, façade systems, and modular building components.

- Industrial Machinery:

Custom machine frames, conveyor systems, automation equipment, and protective enclosures.

- Railway and Mass Transit:

Structural profiles for train carriages, tracks, and infrastructure elements.

- Electronics and Energy:

Heat sinks, enclosures, solar panel frames, and structural supports for renewable energy systems.

- Medical and Laboratory Equipment:

Precision profiles for equipment housings, workstations, and custom fixtures.

- Consumer Goods:

Furniture, sports equipment, and design products that benefit from aluminum's lightness and aesthetic appeal.

Swiss suppliers are adept at meeting the demanding requirements of these industries, offering both standard and highly customized extrusion solutions.

Conclusion

Switzerland's aluminum extrusion press manufacturers and suppliers are globally recognized for their technical excellence, product quality, and commitment to innovation. Companies like Alu Menziken, Kanya AG, and Constellium exemplify the Swiss approach to precision engineering, offering advanced solutions for OEMs, wholesalers, and production companies worldwide. Whether you need standard profiles or complex, custom extrusions, Swiss suppliers provide a unique combination of expertise, flexibility, and reliability.

By understanding the aluminum extrusion process, assessing key selection criteria, and partnering with reputable Swiss manufacturers, international buyers can secure high-quality aluminum extrusions that meet the most demanding application requirements. Switzerland's focus on continuous improvement, sustainability, and customer service ensures that its aluminum extrusion industry will remain a leader on the global stage for years to come.

Frequently Asked Questions

1. What makes Swiss aluminum extrusion press manufacturers and suppliers stand out internationally?

Swiss manufacturers are renowned for their precision engineering, advanced technology, and strict quality control. Their ability to deliver custom, high-performance solutions for demanding industries sets them apart on the global market.

2. How do I select the best aluminum extrusion press manufacturer for my project?

Consider the manufacturer's technical capabilities, quality certifications, customization options, production capacity, customer support, and value-added services. It's also important to assess their experience with your industry and their ability to deliver on time.

3. What types of aluminum alloys do Swiss manufacturers commonly use?

Swiss aluminum extrusion press manufacturers and suppliers typically work with 3xxx, 4xxx, 5xxx, 6xxx, and 7xxx series alloys, each offering specific properties for different applications. Custom alloy development is also available for specialized needs.

4. Can Swiss suppliers provide finished, ready-to-install aluminum components?

Yes, leading Swiss suppliers offer comprehensive post-processing services, including machining, surface finishing, assembly, and packaging, ensuring that components are delivered ready for installation.

5. What is the typical lead time for aluminum extrusions from Swiss manufacturers?

Lead times vary depending on order complexity, volume, and customization. However, Swiss suppliers are known for efficient order processing and reliable delivery, supported by advanced logistics and global networks.