Content Menu

● Introduction to Aluminum Extrusion in Germany

● Understanding the Aluminum Extrusion Process

>> 1. Billet Preparation

>> 2. Extrusion

>> 3. Cooling and Cutting

>> 4. Stretching and Straightening

>> 5. Finishing and Fabrication

● Leading Aluminum Extrusion Press Manufacturers and Suppliers in Germany

>> SMS group GmbH

>> Hydro Extrusion Deutschland GmbH

>> apt Group (apt Extrusions GmbH & Co. KG)

>> Exlabesa (Weseralu GmbH & Co. KG)

>> Arconic Extrusions Hannover GmbH

>> Alu Menziken

>> ST Extruded Products Germany GmbH (STEP-G)

>> Hueck Industrie Holding KG

● Technological Innovations and Sustainability Initiatives

>> Hybrid Drive Systems

>> Automation and Digitalization

>> Sustainability

>> Advanced Alloys and Custom Materials

● OEM and Customization Capabilities

>> Custom Profile Design

>> Precision CNC Machining

>> Surface Treatment and Finishing

>> Flexible Production

>> Assembly and Logistics

● Industry Applications and Market Trends

>> Automotive Industry

>> Aerospace Industry

>> Construction and Architecture

>> Electronics and Energy

>> Market Trends

● How to Select the Right German Aluminum Extrusion Partner

● Conclusion

● Frequently Asked Questions

>> 1. What are the main benefits of working with German Aluminum Extrusion Press Manufacturers and Suppliers?

>> 2. How do German manufacturers ensure product quality and consistency?

>> 3. Can German suppliers handle both large and small order volumes?

>> 4. What alloys are commonly used by German aluminum extrusion companies?

>> 5. What value-added services do German Aluminum Extrusion Press Manufacturers and Suppliers provide?

Germany is globally recognized for its engineering excellence, technological innovation, and commitment to quality—qualities that are especially evident in its aluminum extrusion industry. As the demand for lightweight, durable, and sustainable materials continues to rise, German Aluminum Extrusion Press Manufacturers and Suppliers have become indispensable partners for OEMs, brand owners, wholesalers, and manufacturers worldwide. This article provides an in-depth exploration of the German aluminum extrusion sector, highlighting its leading companies, advanced technologies, and the unique advantages it offers to international clients.

Introduction to Aluminum Extrusion in Germany

Germany's reputation as a hub for high-quality manufacturing extends to its aluminum extrusion industry. The country's manufacturers are known for their precision engineering, rigorous quality control, and ability to deliver tailored solutions for diverse industries. As a result, Germany has become a preferred source for Aluminum Extrusion Press Manufacturers and Suppliers, serving clients across automotive, aerospace, construction, electronics, and renewable energy sectors.

German companies benefit from a highly skilled workforce, a strong culture of innovation, and strict adherence to European Union regulations regarding quality and environmental protection. These factors contribute to the reliability, efficiency, and sustainability of German-made aluminum extrusions.

Understanding the Aluminum Extrusion Process

Aluminum extrusion is a versatile manufacturing process that transforms aluminum billets into profiles with consistent cross-sectional shapes. The process involves several stages:

1. Billet Preparation

Aluminum billets, typically made from high-purity aluminum or recycled material, are cut to size and preheated to a specific temperature. This softens the metal, making it easier to extrude.

2. Extrusion

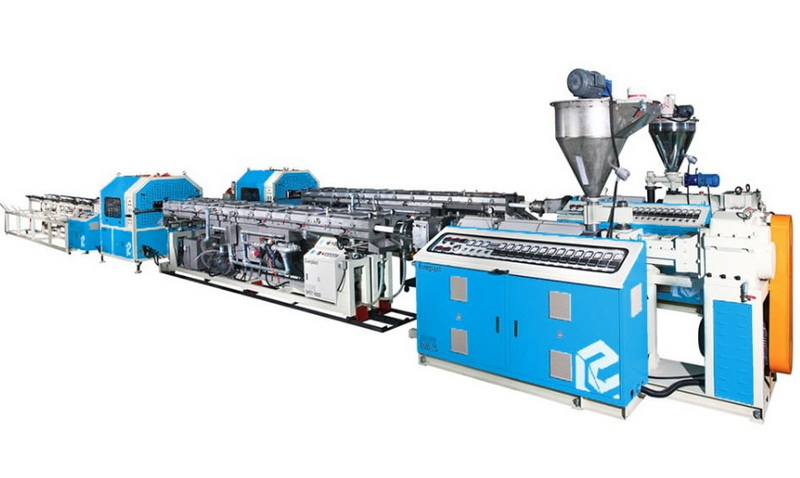

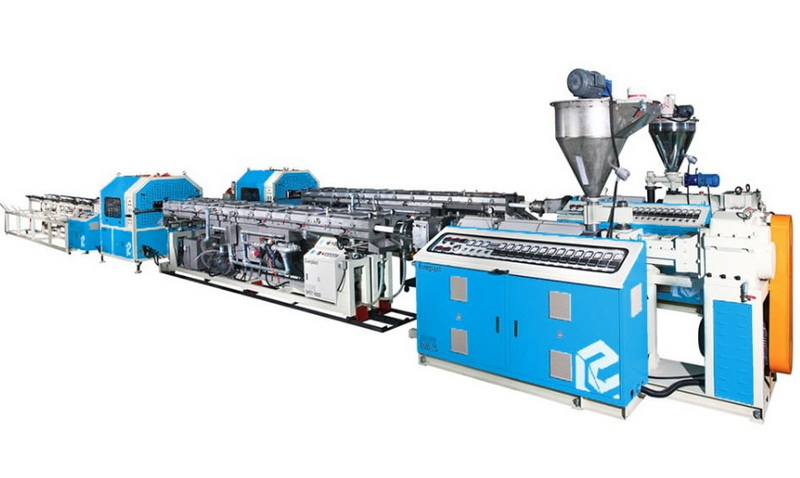

The heated billet is placed into the extrusion press, where a hydraulic ram pushes it through a precision-engineered die. The shape of the die determines the cross-section of the extruded profile. German Aluminum Extrusion Press Manufacturers and Suppliers are renowned for producing dies with extremely tight tolerances, ensuring consistent quality.

3. Cooling and Cutting

After exiting the die, the extruded aluminum profile is rapidly cooled, usually with water or air. This step helps maintain the desired shape and mechanical properties. The profiles are then cut to the required lengths.

4. Stretching and Straightening

To correct any distortions that may occur during extrusion, the profiles are stretched and straightened. This process ensures dimensional accuracy and enhances the material's mechanical strength.

5. Finishing and Fabrication

Depending on customer requirements, extruded profiles may undergo additional processes such as CNC machining, drilling, punching, anodizing, powder coating, or assembly. These value-added services enable German suppliers to deliver finished components ready for integration into final products.

Leading Aluminum Extrusion Press Manufacturers and Suppliers in Germany

Germany is home to a diverse array of Aluminum Extrusion Press Manufacturers and Suppliers, ranging from large multinational corporations to specialized local firms. Here are some of the most prominent players in the industry:

SMS group GmbH

SMS group is a global leader in the development and manufacture of aluminum extrusion presses. Their HybrEx® series of presses are known for their energy efficiency, precision, and high productivity. SMS group's presses are widely used by leading extruders in Germany and around the world, supporting industries such as automotive, construction, and transportation.

Hydro Extrusion Deutschland GmbH

Hydro is one of the world's largest aluminum producers, with several extrusion plants in Germany. Their facilities in Rackwitz and Uphusen operate multiple extrusion presses and are certified by the Aluminium Stewardship Initiative for responsible sourcing and sustainable production. Hydro's recent investments in new presses and expanded fabrication capabilities underscore its commitment to meeting the evolving needs of global customers.

apt Group (apt Extrusions GmbH & Co. KG)

The apt Group operates two major extrusion facilities in Germany, with a combined annual capacity of 80,000 tons. Known for their ability to produce complex profiles, apt Group serves a wide range of industries, including building, transportation, and industrial manufacturing. Their recent installation of a state-of-the-art 27-MN extrusion press from SMS group has further enhanced their capabilities.

Exlabesa (Weseralu GmbH & Co. KG)

Exlabesa acquired Weseralu and operates two extrusion lines in Minden, with a capacity of 13,000 tonnes per year. The company offers a broad portfolio of alloys (including 3XXX, 6XXX, and 7XXX series) and advanced finishing options such as anodizing and powder coating. Exlabesa serves over 400 customers across mechanical, electrical, automotive, railway, and construction sectors.

Arconic Extrusions Hannover GmbH

Arconic is a long-established name in the German aluminum extrusion industry, specializing in high-strength extrusions for aerospace, automotive, and industrial applications. The company is known for its strong community engagement and partnerships with local universities, as well as its ability to produce critical components such as aircraft wing stringers and automotive seat tracks.

Alu Menziken

Alu Menziken is renowned for its expertise in producing profiles with complex cross-sections and tight tolerances. The company supplies the automotive, aerospace, and industrial markets, and is particularly skilled in developing custom materials for OEM partners, including crash-resistant alloys for the automotive sector.

ST Extruded Products Germany GmbH (STEP-G)

STEP-G is a major manufacturer of extruded aluminum profiles and extrusion presses, catering to a broad spectrum of industrial needs. Their technical know-how and flexible production capabilities make them a preferred partner for both large-scale and specialized projects.

Hueck Industrie Holding KG

Hueck specializes in the development and manufacture of aluminum extrusion presses, offering comprehensive solutions for both industrial and architectural applications. Their commitment to innovation and customer service has earned them a strong reputation in the German and European markets.

Technological Innovations and Sustainability Initiatives

German Aluminum Extrusion Press Manufacturers and Suppliers are at the forefront of technological advancement. Their commitment to innovation is evident in several key areas:

Hybrid Drive Systems

Companies like SMS group have pioneered hybrid drive systems, such as the HybrEx® press, which utilize electric servomotors alongside traditional hydraulics. This approach significantly reduces energy consumption and increases the precision and speed of the extrusion process.

Automation and Digitalization

German manufacturers are increasingly integrating automation and digital control systems into their extrusion lines. Automated billet handling, robotic profile stacking, and real-time process monitoring enhance productivity, reduce labor costs, and ensure consistent quality.

Sustainability

Sustainability is a core value for German Aluminum Extrusion Press Manufacturers and Suppliers. Many companies use recycled aluminum in their billets, invest in energy-efficient equipment, and comply with stringent EU environmental regulations. Certifications from organizations like the Aluminium Stewardship Initiative further demonstrate their commitment to responsible production.

Advanced Alloys and Custom Materials

German suppliers offer a wide range of aluminum alloys, including high-strength and corrosion-resistant grades. They also collaborate with customers to develop custom alloys tailored to specific performance requirements, such as improved crash resistance for automotive applications or enhanced conductivity for electrical components.

OEM and Customization Capabilities

One of the defining strengths of German Aluminum Extrusion Press Manufacturers and Suppliers is their ability to provide comprehensive OEM (Original Equipment Manufacturer) services. These capabilities include:

Custom Profile Design

German suppliers employ advanced CAD software and precision die manufacturing to create custom profiles that meet exacting customer specifications. Whether clients require simple shapes or highly complex cross-sections, German manufacturers can deliver.

Precision CNC Machining

After extrusion, profiles often require further processing to add holes, slots, or other features. German companies use state-of-the-art CNC machining centers to achieve tight tolerances—often as precise as ±0.02 mm.

Surface Treatment and Finishing

To enhance appearance and performance, extruded profiles can be anodized, powder coated, or painted in a wide range of colors and finishes. These treatments improve corrosion resistance and ensure that components meet aesthetic and functional requirements.

Flexible Production

German Aluminum Extrusion Press Manufacturers and Suppliers are equipped to handle both high-volume production runs and smaller, specialized batches. This flexibility allows them to serve a diverse customer base, from large automotive OEMs to niche industrial manufacturers.

Assembly and Logistics

Many German suppliers offer additional services such as component assembly, packaging, and logistics support. This enables clients to receive fully finished products, streamlining their supply chains and reducing time-to-market.

Industry Applications and Market Trends

Aluminum extrusions produced by German manufacturers are used in a vast array of industries, reflecting the versatility and performance of the material.

Automotive Industry

The automotive sector is a major consumer of aluminum extrusions, which are used to reduce vehicle weight, improve fuel efficiency, and enhance safety. Applications include structural components, crash management systems, battery enclosures for electric vehicles, and decorative trims.

Aerospace Industry

Aluminum extrusions are critical in aerospace applications due to their high strength-to-weight ratio and excellent corrosion resistance. German suppliers produce profiles for aircraft frames, seat tracks, wing stringers, and interior components.

Construction and Architecture

In the construction industry, aluminum extrusions are used for window frames, curtain walls, structural supports, and façade systems. German manufacturers are known for their ability to deliver profiles that meet stringent architectural and engineering standards.

Electronics and Energy

Aluminum's thermal conductivity and electrical properties make it ideal for heat sinks, enclosures, and renewable energy systems such as solar panel frames and mounting structures.

Market Trends

- Sustainability: There is growing demand for aluminum products made from recycled material and produced using energy-efficient processes.

- Electrification: The rise of electric vehicles and renewable energy systems is driving demand for lightweight, high-performance aluminum extrusions.

- Customization: Clients increasingly seek tailored solutions, including custom alloys, complex shapes, and value-added fabrication services.

- Digitalization: The adoption of Industry 4.0 technologies is enhancing efficiency, quality, and traceability throughout the extrusion process.

How to Select the Right German Aluminum Extrusion Partner

Choosing the right Aluminum Extrusion Press Manufacturer or Supplier in Germany involves several key considerations:

- Technical Capabilities: Assess the supplier's ability to produce the required profiles, including their experience with specific alloys, tolerances, and finishing options.

- Quality Assurance: Look for certifications such as ISO 9001, IATF 16949 (for automotive), and Aluminium Stewardship Initiative, which indicate a commitment to quality and sustainability.

- OEM Experience: Select a partner with a proven track record in delivering OEM solutions, including custom design, machining, and assembly services.

- Production Flexibility: Ensure the supplier can accommodate both large and small order volumes, as well as rapid prototyping and short lead times.

- Customer Support: Evaluate the supplier's communication, technical support, and after-sales service to ensure a smooth and successful partnership.

Conclusion

Germany's Aluminum Extrusion Press Manufacturers and Suppliers set the global standard for quality, innovation, and sustainability. Their advanced technologies, skilled workforce, and commitment to customer satisfaction make them ideal partners for international OEMs, brand owners, wholesalers, and manufacturers. Whether you require high-volume production, complex custom profiles, or value-added fabrication services, German suppliers offer the expertise and capabilities to meet your needs. As the world continues to prioritize lightweight, sustainable materials, Germany's aluminum extrusion industry is poised to play an even greater role in shaping the future of manufacturing and engineering.

Frequently Asked Questions

1. What are the main benefits of working with German Aluminum Extrusion Press Manufacturers and Suppliers?

German suppliers offer advanced technology, strict quality control, sustainability, and extensive customization options, ensuring reliable and high-quality solutions for global clients.

2. How do German manufacturers ensure product quality and consistency?

They implement rigorous quality assurance protocols, use state-of-the-art equipment, and adhere to international standards such as ISO 9001 and Aluminium Stewardship Initiative certifications.

3. Can German suppliers handle both large and small order volumes?

Yes, most leading German Aluminum Extrusion Press Manufacturers and Suppliers offer flexible production capabilities, accommodating both high-volume and specialized small-batch orders.

4. What alloys are commonly used by German aluminum extrusion companies?

German suppliers typically use 3XXX, 5XXX, 6XXX, and 7XXX series alloys, selected based on the specific requirements of strength, corrosion resistance, and machinability for each application.

5. What value-added services do German Aluminum Extrusion Press Manufacturers and Suppliers provide?

Services include custom profile design, CNC machining, surface finishing (anodizing, powder coating), assembly, packaging, and logistics support, delivering finished components ready for use.