Content Menu

● Overview of the Russian Aluminum Extrusion Industry

● Leading Aluminum Extrusion Line Manufacturers and Suppliers in Russia

>> BK-ALPROF

>> SEGAL

>> Realit

>> RIAK

>> Tatprof

>> International Aluminium Company (MAK)

● Key Technologies and Innovations

● Why Choose Russian Aluminum Extrusion Line Suppliers?

● Conclusion

● Frequently Asked Questions

>> 1. What are the main products offered by Russian aluminum extrusion line manufacturers and suppliers?

>> 2. Do Russian suppliers provide OEM and custom extrusion services?

>> 3. How do Russian aluminum extrusion companies ensure product quality?

>> 4. What industries do Russian aluminum extrusion suppliers serve?

>> 5. Can Russian manufacturers handle large-scale international orders?

The Russian aluminum industry stands as a global powerhouse, renowned for its advanced technology, robust production capacity, and commitment to quality. As the demand for aluminum extrusion lines and profiles surges across construction, automotive, aerospace, and industrial sectors, Russia's manufacturers and suppliers have positioned themselves as key players in the international market. This article explores the top aluminum extrusion line manufacturers and suppliers in Russia, highlighting their capabilities, innovations, and why they are trusted partners for OEM and custom solutions worldwide.

Overview of the Russian Aluminum Extrusion Industry

Russia boasts a mature and technologically advanced aluminum extrusion sector. The country's manufacturers are equipped with state-of-the-art extrusion presses, automated production lines, and comprehensive finishing facilities. These companies not only supply the domestic market but also export to Europe, Asia, the Middle East, and the Americas, serving industries that demand high-quality, precision-engineered aluminum profiles.

Key strengths of Russian aluminum extrusion line manufacturers and suppliers include:

- High production capacity: Many plants produce tens of thousands of tons annually.

- Advanced automation and quality control: Computerized systems ensure precision and efficiency.

- Diverse product range: From standard profiles to complex custom extrusions for architectural, automotive, and industrial applications.

- Compliance with international standards: Certifications such as ISO 9001:2015 and TÜV NORD CERT guarantee product quality.

- Strong R&D and innovation focus: Continuous investment in technology and product development.

The combination of these factors has enabled Russian manufacturers to compete effectively on the global stage, offering cost-effective, reliable, and customizable aluminum extrusion solutions.

Leading Aluminum Extrusion Line Manufacturers and Suppliers in Russia

BK-ALPROF

BK-ALPROF is a leading name among aluminum extrusion line manufacturers and suppliers in Russia. Established in 2003, BK-ALPROF operates a modern plant in Belaya Kalitva, Rostov region, and has quickly become a trusted partner for both domestic and international clients.

Key Features:

- Production Capacity: 20,000 tons of aluminum profiles per year.

- Equipment: Three press lines, including advanced hydraulic presses (12.5 MN and 18 MN), and a foundry for casting cylindrical ingots.

- Technological Edge: Regular equipment modernization, including automatic press control systems and updated heating furnaces, boosting productivity by up to 30%.

- Product Range: Standard and custom extruded profiles, machining, coating, painting, anodic oxidation, and translucent structures.

- Quality Assurance: ISO 9001:2015 certified, with continuous improvement and international recognition.

BK-ALPROF's commitment to innovation and quality has earned it a solid reputation among OEM clients, wholesalers, and manufacturers worldwide. The company's ability to adapt to customer-specific requirements and deliver on time makes it a preferred supplier in the aluminum extrusion market.

SEGAL

SEGAL Ltd., part of the SIAL Group, is a leader in producing aluminum profiles for the architectural sector. Based in Krasnoyarsk, SEGAL has invested heavily in upgrading its extrusion lines and hydraulic systems.

Key Features:

- Production Capacity: 32,000 tons annually.

- Capabilities: Casting, extrusion, finishing (painting, anodizing), assembly of facades and frameworks.

- Innovation: Recent modernization of the P2500 MT extrusion line, reducing press dead time and increasing efficiency.

- Quality Control: In-house analytical laboratory and comprehensive packaging area.

SEGAL's focus on architectural aluminum profiles has positioned it as a key supplier for large-scale construction projects across Russia and neighboring countries. Its ability to produce complex profiles with tight tolerances and superior surface finishes meets the stringent demands of modern architectural design.

Realit

Realit stands out for its high-quality extrusion billets, profiles, and architectural systems. Located in Obninsk, Kaluga region, Realit's factory is equipped with advanced European machinery and produces 1,700 tons of aluminum profiles per month.

Key Features:

- Production Capacity: 20,400 tons per year.

- Expertise: Design, manufacturing, fabrication, surface treatment, and finishing.

- Customer Orientation: Offers tailored solutions from early-stage design to finished product delivery.

- Global Sales: Exports worldwide, ensuring fast delivery and just-in-time logistics.

Realit's comprehensive approach—from design through final finishing—provides customers with a seamless experience. The company's ability to quickly adapt to changing market demands and develop innovative profile solutions makes it a valuable partner for international brands and manufacturers.

RIAK

RIAK is an innovative manufacturer of aluminum extrusion profiles, serving the construction, automotive, electrical, and mechanical engineering industries. Based in Magas, Ingushetia, RIAK leverages modern European equipment and automated control systems.

Key Features:

- Equipment: Two extrusion presses, chemical treatment shop, two powder coating lines, and automatic packing.

- Customization: Precision profiles from 1.5 to 7 meters, including non-standard products to customer specifications.

- Quality Assurance: High-quality raw materials, compliance with Russian and international standards, and certified finished products.

- Export Markets: Supplies to Russia, CIS, Turkey, UAE, and the EU.

RIAK's dedication to quality and customization allows it to serve a diverse client base with specific technical requirements. The company's investment in surface treatment technologies ensures durable and aesthetically pleasing profiles suitable for demanding environments.

Tatprof

Tatprof, under the RASSTAL management structure, ranks among the top three Russian aluminum extrusion manufacturers. With a focus on construction cladding, interior structures, and custom profiles, Tatprof operates high-speed finishing lines and advanced powder coating systems.

Key Features:

- Finishing Systems: Two ideal-line finishing systems (installed in 2008 and 2011), capable of handling multiple colors and high throughput.

- Product Range: Cladding, interior, and drawing profiles for the construction industry.

- Quality Reputation: Known for consistent high quality and customization for diverse project needs.

Tatprof's ability to combine extrusion with sophisticated finishing processes makes it a one-stop solution for customers requiring ready-to-install aluminum components. Its products are widely used in commercial and residential construction projects.

International Aluminium Company (MAK)

International Aluminium Company (MAK) is a reliable supplier and leading manufacturer of extrusion profiles, with a proactive approach and modern equipment.

Key Features:

- Product Diversity: Over 5,000 types of aluminum profiles for building, automotive, and machine-building industries.

- Presses: Multiple extrusion presses (ranging from 1,000 to 4,000 US tons).

- Finishing: Horizontal and vertical powder painting lines.

- Custom Solutions: Offers profile development based on customer drawings and samples.

- Quality Control: Stage-by-stage inspection throughout the manufacturing cycle.

MAK's extensive product catalog and ability to produce custom profiles make it a versatile supplier for a wide range of industrial applications. The company's commitment to quality and customer service ensures long-term partnerships with OEMs and wholesalers.

Key Technologies and Innovations

Russian aluminum extrusion line manufacturers and suppliers are at the forefront of technological advancement in the industry. Some of the key innovations include:

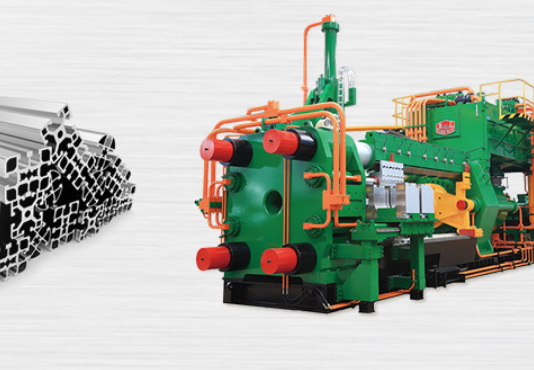

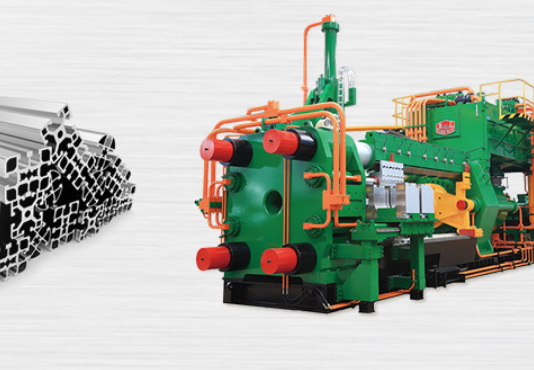

- Automated Extrusion Presses: High-tonnage presses with computerized control systems for precision and efficiency. These presses allow for consistent profile dimensions and improved energy efficiency.

- Advanced Surface Treatments: Anodizing, powder coating, and painting lines for enhanced durability and aesthetics. These finishing technologies protect aluminum profiles from corrosion and wear while offering a variety of color and texture options.

- Integrated Foundries: On-site foundries for casting billets, ensuring a stable supply of high-quality raw materials. This vertical integration reduces lead times and improves quality control.

- Custom Profile Design: CAD/CAM-driven design and prototyping for bespoke applications. This capability enables manufacturers to meet unique customer specifications and accelerate product development cycles.

- Quality Management Systems: ISO-certified processes and rigorous inspection at every stage. These systems guarantee that products meet international standards for mechanical properties, surface finish, and dimensional accuracy.

Furthermore, many Russian manufacturers are investing in sustainable production practices, such as recycling aluminum scrap and optimizing energy consumption. These efforts align with global trends toward environmental responsibility and circular economy principles.

Why Choose Russian Aluminum Extrusion Line Suppliers?

Choosing a Russian aluminum extrusion line manufacturer or supplier offers several advantages:

- Competitive Pricing: Efficient production and local raw materials translate to cost-effective solutions without compromising quality.

- OEM/ODM Expertise: Russian suppliers excel in providing OEM services for international brands, wholesalers, and manufacturers, offering tailored solutions and flexible production runs.

- Global Logistics: Experience in exporting to multiple continents ensures reliable and timely delivery, with established partnerships for shipping and customs clearance.

- Technical Support: Skilled engineers and technicians offer end-to-end support, from design consultation and prototyping to after-sales service and troubleshooting.

- Sustainability: Many Russian companies invest in energy-efficient technologies and recycling, aligning with global sustainability goals and customer expectations.

The combination of these factors makes Russian aluminum extrusion line manufacturers and suppliers highly attractive partners for companies seeking reliable, innovative, and cost-effective aluminum extrusion solutions.

Conclusion

Russia's aluminum extrusion line manufacturers and suppliers have established themselves as leaders in the global market by combining advanced technology, high production capacity, and a strong commitment to quality. Companies such as BK-ALPROF, SEGAL, Realit, RIAK, Tatprof, and MAK offer comprehensive OEM and custom extrusion services that meet the diverse needs of industries ranging from construction to automotive and aerospace.

Their continuous investment in automation, surface treatment technologies, and sustainable practices ensures that they remain competitive and responsive to evolving market demands. For international brands, wholesalers, and manufacturers seeking reliable partners, Russian aluminum extrusion line suppliers provide a compelling blend of expertise, innovation, and value.

Frequently Asked Questions

1. What are the main products offered by Russian aluminum extrusion line manufacturers and suppliers?

Russian manufacturers offer a wide range of aluminum profiles, including standard shapes (angles, channels, tubes, bars, beams), custom-designed profiles, architectural systems, automotive components, and finished products with various surface treatments.

2. Do Russian suppliers provide OEM and custom extrusion services?

Yes, most leading Russian aluminum extrusion line manufacturers and suppliers provide OEM and ODM services, working closely with international brands, wholesalers, and manufacturers to deliver custom solutions based on specific requirements.

3. How do Russian aluminum extrusion companies ensure product quality?

Quality is ensured through ISO-certified management systems, use of high-quality raw materials, advanced production technology, and rigorous inspection at every stage of manufacturing. Many companies also provide certificates of conformity with international standards.

4. What industries do Russian aluminum extrusion suppliers serve?

Russian suppliers serve a broad range of industries, including construction, automotive, aerospace, electrical, mechanical engineering, furniture, and more.

5. Can Russian manufacturers handle large-scale international orders?

Yes, with high production capacities (up to 32,000 tons per year for some companies), advanced logistics, and experience in global export, Russian aluminum extrusion line manufacturers and suppliers are well-equipped to handle large-scale international orders.