Content Menu

● Why Portugal Is a Strategic Location for Aluminum Extrusion

● Leading Aluminum Extrusion Line Manufacturers and Suppliers in Portugal

>> Exlabesa

>> STRUGAL

>> GAP Aluminium

● The Aluminum Extrusion Process: An Overview

● Technological Advancements in Portugal's Aluminum Extrusion Industry

● Sustainability Initiatives

● Market Trends and Future Outlook

● Partnering with Portuguese Aluminum Extrusion Line Manufacturers and Suppliers

● Comparison Table of Leading Manufacturers

● Conclusion

● Frequently Asked Questions (FAQs)

>> Q1: What alloys can Portuguese extrusion press manufacturers process?

>> Q2: How do Portuguese suppliers ensure sustainability in aluminum extrusion?

>> Q3: What is the typical production capacity of a modern extrusion facility in Portugal?

>> Q4: Are OEM and custom extrusion services available?

>> Q5: What are the main industries served by Portuguese aluminum extrusion press manufacturers?

Portugal has established itself as a significant hub for Aluminum Extrusion Line Manufacturers and Suppliers in Europe. This development results from a combination of strategic geographic advantages, advanced manufacturing technology, and a strong commitment to sustainability and quality. The Portuguese aluminum extrusion industry serves a broad spectrum of sectors, including construction, transportation, infrastructure, and renewable energy. This article provides an in-depth overview of the top aluminum extrusion line manufacturers and suppliers in Portugal, their technological capabilities, production capacities, and the benefits they offer to international OEMs, wholesalers, and producers. We will also explore the aluminum extrusion process, recent technological advancements, sustainability initiatives, and market trends shaping the industry.

Why Portugal Is a Strategic Location for Aluminum Extrusion

Portugal's geographic position in southern Europe offers excellent access to key European markets such as Spain, France, and beyond. This strategic location facilitates efficient logistics and distribution, enabling manufacturers to serve clients across Europe and internationally with shorter lead times and reduced shipping costs.

In addition to its location, Portugal benefits from a skilled and experienced workforce specialized in aluminum manufacturing and extrusion technologies. The country's industrial infrastructure supports high-volume production with modern facilities equipped with cutting-edge machinery. Moreover, Portugal's commitment to environmental standards and sustainability has attracted global brands seeking responsible manufacturing partners.

Leading Aluminum Extrusion Line Manufacturers and Suppliers in Portugal

Exlabesa

Exlabesa is a multinational company that recently inaugurated a state-of-the-art extrusion facility in João Rui Ferreira, Portugal. This plant represents a cornerstone of their southern European strategy and is designed to meet growing demand for high-quality aluminum profiles.

- Facility Size and Capacity: The plant occupies an 86,000 square meter plot with 10,000 square meters of covered production area. Initially, it has a production capacity of 16,000 tonnes per year, with plans to expand to over 45,000 tonnes.

- Extrusion Lines: The facility currently operates two 2,800-tonne extrusion presses, with plans to add three additional presses — two 3,500-tonne and one 4,500-tonne — to increase capacity and flexibility.

- Alloys and Profiles: Exlabesa processes a wide range of 6000 series aluminum alloys, including 6005, 6060, 6061, 6063, 6082, 6101, and 6106. The plant can produce profiles up to 7.2 meters long, with diverse cross-sectional shapes and thicknesses.

- Surface Treatment: The facility includes a vertical powder coating line capable of finishing profiles with high durability and aesthetic quality.

- Sustainability: Exlabesa emphasizes environmental responsibility by using recycled aluminum with a carbon footprint as low as 2.95 kg CO₂e per kg of aluminum, certified by Bureau Veritas. Their processes comply with ISO 9001, CE marking, Qualicoat, and the Alu+C- environmental label.

- Markets Served: The company supplies profiles for construction, transport, infrastructure, and renewable energy sectors, serving both Iberian and broader European markets.

STRUGAL

STRUGAL is one of the most modern and well-equipped extrusion companies in Europe, with significant operations in Portugal.

- Production Capacity: STRUGAL's Portuguese plants have an annual capacity of 42,000 tonnes of aluminum profiles.

- Extrusion Presses: The company operates multiple extrusion presses ranging from 1,400 to 2,200 tonnes, capable of producing a wide variety of profiles.

- Material and Finishing: STRUGAL processes all 6000 series alloys and offers various heat treatments such as T4, T5, T6, and T66. Profiles can be produced in lengths from 3 to 14 meters, with weights between 0.04 kg/m and 35 kg/m and thicknesses from 1 mm to 70 mm.

- Certifications and Quality: STRUGAL adheres to ISO 9001, EN 755-9, and 12020-2 standards, ensuring high-quality products suitable for demanding architectural and industrial applications.

- Market Focus: Their aluminum extrusion lines cater to architectural projects, industrial applications, and OEM clients across Europe.

GAP Aluminium

GAP Aluminium specializes in the repair, maintenance, and refurbishment of extrusion lines, supporting both local and international extrusion factories.

- Experience and Expertise: With over 25 years of experience, GAP Aluminium services all major extrusion line brands, including SMS, Turla, Tecalex, GIA, and Sutton.

- Service Offerings: Their services include mechanical repairs, hydraulic system maintenance, programming, furnace upkeep, lacquering, and anodizing upgrades.

- Customization: GAP Aluminium provides tailored equipment upgrades to improve energy efficiency, productivity, and product quality for extrusion lines.

- Client Support: They offer comprehensive technical support and after-sales service, ensuring extrusion lines operate at peak performance.

The Aluminum Extrusion Process: An Overview

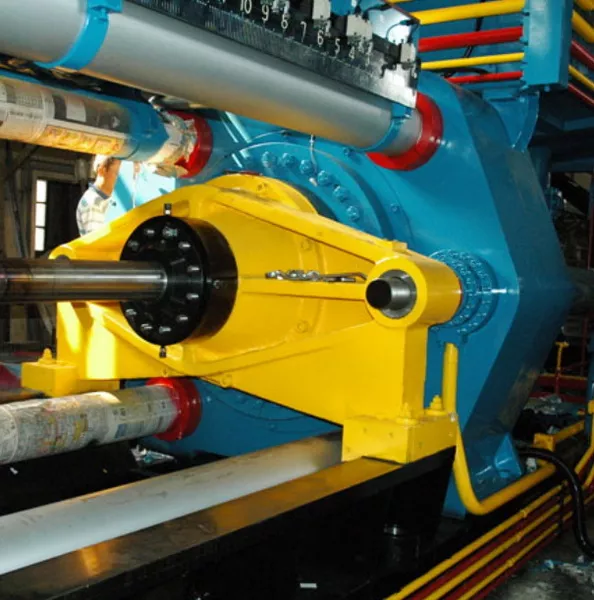

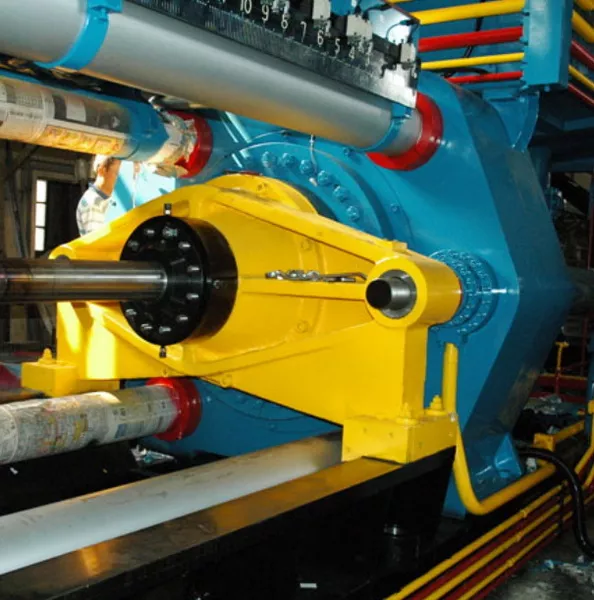

Understanding the aluminum extrusion process is essential to appreciating the capabilities of Portugal's manufacturers and suppliers. The extrusion process transforms raw aluminum billets into precise, custom profiles by forcing heated aluminum through a shaped die.

1. Die Preparation: High-strength steel dies are machined to match the desired profile shape. These dies are preheated to approximately 450–500°C to ensure smooth extrusion and prevent cracking.

2. Billet Preheating: Aluminum billets are heated to 400–500°C, making them malleable enough to be pushed through the die.

3. Extrusion: A hydraulic ram applies immense pressure — sometimes up to 15,000 tons — to push the heated billet through the die, creating continuous aluminum profiles.

4. Cooling and Quenching: The extruded profiles are cooled either naturally or with air/water quenching to preserve their metallurgical properties.

5. Stretching and Cutting: Profiles are straightened and cut to specified lengths.

6. Aging: Heat treatments (artificial aging) are applied to enhance the strength and hardness of the profiles.

7. Surface Finishing: Profiles undergo surface treatments such as powder coating or anodizing to improve corrosion resistance and aesthetics.

This process allows manufacturers to produce complex shapes with tight tolerances, meeting the diverse needs of various industries.

Technological Advancements in Portugal's Aluminum Extrusion Industry

Portuguese aluminum extrusion line manufacturers have embraced several technological advancements to improve product quality, efficiency, and sustainability:

- Automated Press Controls: Modern extrusion presses are equipped with real-time monitoring systems that track pressure, temperature, and extrusion speed. These controls ensure consistent quality and reduce waste.

- Energy Efficiency: Companies have optimized their extrusion presses and furnaces to lower energy consumption. Heat recovery systems and variable frequency drives contribute to significant energy savings.

- Advanced Alloys Processing: Portuguese manufacturers are capable of processing high-strength and specialty aluminum alloys, catering to demanding applications in aerospace, automotive, and renewable energy.

- Surface Finishing Technologies: Vertical powder coating lines and advanced anodizing facilities allow for superior surface finishes, enhancing corrosion resistance and visual appeal.

- Industry 4.0 Integration: Some manufacturers are integrating Industry 4.0 technologies such as IoT sensors, predictive maintenance, and data analytics to optimize production and reduce downtime.

Sustainability Initiatives

Sustainability is a core value for Portugal's aluminum extrusion industry. Manufacturers are committed to reducing environmental impact through:

- Use of Recycled Aluminum: Many companies use recycled aluminum billets, significantly reducing carbon emissions compared to primary aluminum production.

- Waste Management: Efficient recycling of scrap material and waste products minimizes landfill and resource consumption.

- Energy Management: Adoption of renewable energy sources and energy-efficient equipment reduces the carbon footprint of extrusion operations.

- Certifications: Compliance with international standards such as ISO 9001, Qualicoat, and the Alu+C- environmental label demonstrates commitment to quality and environmental responsibility.

- Carbon Footprint Transparency: Leading companies provide verified carbon footprint data for their products, enabling clients to make informed sustainability choices.

Market Trends and Future Outlook

The aluminum extrusion industry in Portugal is poised for continued growth, driven by several key trends:

- Lightweighting in Transportation: Increasing demand for lightweight materials in automotive and aerospace sectors boosts demand for aluminum profiles.

- Sustainable Construction: Aluminum's recyclability and durability make it ideal for green building projects.

- Customization and OEM Services: Clients increasingly seek tailored extrusion solutions and value-added services, encouraging manufacturers to expand their OEM capabilities.

- Technological Innovation: Advances in extrusion technology and digitalization enhance production flexibility and quality.

- Global Expansion: Portuguese manufacturers leverage their location and capabilities to expand into new international markets.

Partnering with Portuguese Aluminum Extrusion Line Manufacturers and Suppliers

For OEMs, wholesalers, and producers worldwide, partnering with Portuguese manufacturers offers several advantages:

- Custom Design and Production: Portuguese suppliers provide tailored extrusion profiles and surface finishes to meet specific client requirements.

- Technical Expertise: Comprehensive support, including die design, process optimization, and after-sales service, ensures high-quality outcomes.

- Competitive Pricing: Efficient production methods and logistics networks enable competitive pricing without compromising quality.

- Innovation and Sustainability: Portuguese manufacturers invest in R&D and sustainable practices, aligning with global market demands.

Comparison Table of Leading Manufacturers

| Company | Facility Size | Annual Capacity | Key Technologies | Main Markets Served | Certifications |

| Exlabesa | 86,000 sq m | 16,000–45,000 tonnes | SMS Group presses, vertical coating | Construction, transport, infrastructure | ISO 9001, CE, Qualicoat, Alu+C- |

| STRUGAL | Multi-site | 42,000 tonnes | Multiple presses (1,400–2,200 t) | Architecture, industry | ISO 9001, EN 755-9, 12020-2 |

| GAP Aluminium | Service provider | N/A | Repairs, maintenance, upgrades | OEMs, extrusion factories | N/A |

Conclusion

Portugal stands out as a premier destination for Aluminum Extrusion Line Manufacturers and Suppliers, combining advanced technology, high production capacity, and a strong commitment to sustainability. Leading companies such as Exlabesa, STRUGAL, and GAP Aluminium provide comprehensive OEM services, cutting-edge extrusion lines, and expert technical support to meet the diverse needs of international clients. Portugal's strategic location, skilled workforce, and ongoing innovation make it an ideal partner for businesses seeking high-quality aluminum extrusion solutions. As global demand for lightweight, durable, and sustainable materials grows, Portugal's aluminum extrusion industry is well-positioned for continued success and expansion.

Frequently Asked Questions (FAQs)

Q1: What alloys can Portuguese extrusion press manufacturers process?

A1: Portuguese manufacturers commonly process all 6000 series aluminum alloys, including 6005, 6060, 6061, 6063, 6082, 6101, and 6106, suitable for a wide range of applications.

Q2: How do Portuguese suppliers ensure sustainability in aluminum extrusion?

A2: They use recycled aluminum billets, implement waste recycling programs, adopt energy-efficient technologies, and hold certifications such as ISO 9001 and Alu+C- to minimize environmental impact.

Q3: What is the typical production capacity of a modern extrusion facility in Portugal?

A3: Facilities like Exlabesa's produce 16,000 tonnes annually, with expansion plans to exceed 45,000 tonnes, while STRUGAL operates at around 42,000 tonnes per year.

Q4: Are OEM and custom extrusion services available?

A4: Yes, Portuguese manufacturers offer comprehensive OEM services, including custom die design, profile fabrication, and finishing tailored to client specifications.

Q5: What are the main industries served by Portuguese aluminum extrusion press manufacturers?

A5: The main industries include construction, transportation, infrastructure, renewable energy, and industrial machinery sectors.