Content Menu

● Introduction to Aluminum Extrusion in Japan

● Leading Aluminum Extrusion Equipment Manufacturers And Suppliers in Japan

>> 1. UACJ Corporation

>> 2. UBE Machinery Corporation, Ltd.

>> 3. Nikkei MC Aluminium Co. Ltd. / Nikkeikin Holdings

>> 4. Asahi Aluminium Co. Ltd.

>> 5. Shibaura Machine

● Technologies and Equipment Adopted by Japanese Aluminum Extrusion Manufacturers

● Selecting the Right Japanese Aluminum Extrusion Equipment Manufacturer or Supplier

● Industries Benefiting from Japanese Aluminum Extrusion Equipment

● The Future Outlook for Aluminum Extrusion in Japan

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the primary advantage of choosing Japanese aluminum extrusion equipment manufacturers and suppliers compared to others?

>> 2. Can Japanese suppliers customize aluminum extrusions for unique industrial needs?

>> 3. What certifications do reputable Japanese aluminum extrusion suppliers hold?

>> 4. How does using aluminum extrusion benefit automotive manufacturing?

>> 5. Are Japanese aluminum extrusion suppliers open to international partnerships and OEM cooperation?

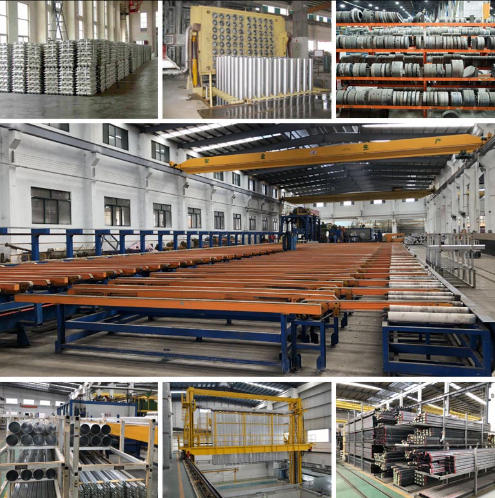

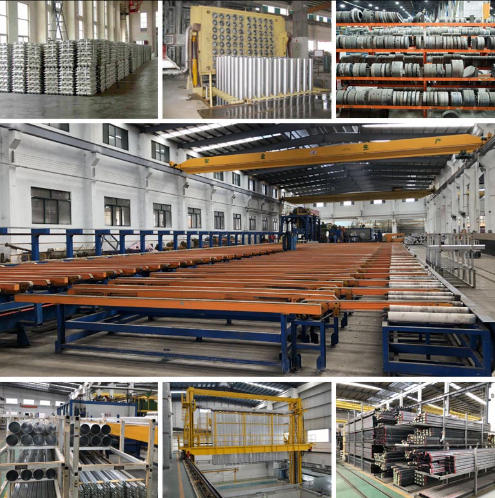

The aluminum extrusion industry in Japan is renowned worldwide for its technological advancements, high precision, and strong commitment to quality. Japanese manufacturers and suppliers have long been at the forefront of innovation in aluminum extrusion equipment, serving a diverse set of industries and providing vital OEM (Original Equipment Manufacturer) solutions to foreign brands, wholesalers, and producers globally. This article offers an in-depth exploration into the leading aluminum extrusion equipment manufacturers and suppliers in Japan, their advanced technologies, and what makes them premier partners in this specialized sector.

Introduction to Aluminum Extrusion in Japan

Aluminum extrusion is a manufacturing process whereby heated aluminum alloy billets are forced through a shaped die to produce long, continuous profiles with intricate cross-sectional designs. This method is widely used for producing components required in architectural elements, automotive parts, electronic housings, and structural frameworks.

Japan's aluminum extrusion industry distinguishes itself due to years of investment in sophisticated manufacturing technologies, rigorous quality control protocols, and a responsiveness to diverse market demands. Japanese companies not only produce world-class extrusion equipment but also offer comprehensive services that include die design, testing, finishing processes, and aftermarket support—making them highly desirable partners for OEM collaborations and export markets.

Leading Aluminum Extrusion Equipment Manufacturers And Suppliers in Japan

The Japanese market features a range of highly reputable companies—each offering unique capabilities and technologies that collectively raise the bar in aluminum extrusion equipment quality.

1. UACJ Corporation

UACJ Corporation stands out as one of Japan's largest and most internationally respected manufacturers of aluminum products, including extrusion machinery and related equipment. Formed from the merger of several prominent producers, UACJ has consolidated extensive technical know-how and state-of-the-art production infrastructure, enabling it to address a wide spectrum of extrusion needs.

UACJ's extrusion equipment portfolio includes both direct and indirect extrusion presses capable of handling billets from 6 inches to 16 inches in diameter, positioning the company as the top capacity holder in Japan for indirect extrusion machinery. Their manufacturing lines also incorporate unique vertical quenching furnaces that enhance profile tolerances and mechanical properties.

Apart from extrusion presses, UACJ offers full machining services—such as 3D bending, drilling, die cutting, and numerical control (NC) processing—allowing customers to receive finished parts ready for assembly. The company is particularly strong in serving automotive, aerospace, electronics, and industrial equipment sectors.

2. UBE Machinery Corporation, Ltd.

UBE Machinery is a premier supplier of aluminum extrusion equipment in Japan with over 60 years of experience. Their extrusion presses, especially their SS Series stem-slide direct extrusion machines, are highly acclaimed for combining energy efficiency with unmatched precision.

UBE's capability extends to indirect double-action extrusion presses designed to provide highly uniform metal flow with minimal friction—a critical factor in producing high-quality extrusions. Beyond machinery sales, UBE emphasizes automation by integrating billet loaders, die cassette changers, and IoT-driven monitoring systems to optimize the production process and reduce downtime.

Their commitment to customer service includes machine repair, consulting, and retrofit offerings, allowing manufacturers to extend equipment lifecycle and maintain competitive edge.

3. Nikkei MC Aluminium Co. Ltd. / Nikkeikin Holdings

Nikkei MC Aluminium, operating under Nikkeikin Holdings, is a company with a rich tradition in producing high-performance aluminum sheets and extruded products. They focus heavily on research and development to customize alloys and extrusion methods tailored to the needs of the automotive, electronics, and construction industries.

Their integration into global supply chains and focus on flexible manufacturing processes have made Nikkei MC Aluminium a trusted supplier for customers seeking innovation combined with proven reliability.

4. Asahi Aluminium Co. Ltd.

Asahi Aluminium is known for its long heritage and customer-centric approach. Offering a diverse product portfolio, the company produces a variety of extruded aluminum profiles that serve both domestic and international markets. Their expertise includes customized solutions that meet stringent industrial requirements, supported by consistent quality assurance processes.

5. Shibaura Machine

Although Shibaura Machine is broadly recognized for its machine tool engineering, it also plays a significant role in the extrusion equipment market. Their extrusion presses and associated machinery support high-end production applications in Japan, blending precision engineering with scalable production capabilities.

Technologies and Equipment Adopted by Japanese Aluminum Extrusion Manufacturers

Japanese manufacturers consistently employ cutting-edge technologies to enhance the precision, productivity, and energy efficiency of their extrusion equipment:

- Direct and Indirect Extrusion Presses: Japanese manufacturers produce high-capacity direct presses for straightforward profiles and indirect presses that reduce billet waste and tooling wear. This versatility caters to varied product specifications and volume requirements.

- Automated Handling and Quenching Equipment: Automation for billet loading, profile handling, and quenching ensures product consistency, essential for sectors like aerospace and automotive where material properties must meet exacting standards.

- Advanced CNC Machining and Finishing: Japanese suppliers integrate precise machining steps such as cutting, bending, drilling, and surface treatments (anodizing, powder coating) inline with extrusion—delivering profiles that reduce secondary processing costs for clients.

- IoT and Industry 4.0 Integration: Several leading companies implement Internet of Things (IoT)-enabled machinery to facilitate real-time performance monitoring, predictive maintenance, and optimized energy consumption.

- Research-Driven Alloy Development: Collaboration with metallurgical R&D institutes enables these manufacturers to offer custom alloys and extrusion solutions to address specialized applications such as lightweight automotive parts or corrosion-resistant architectural components.

Selecting the Right Japanese Aluminum Extrusion Equipment Manufacturer or Supplier

For companies worldwide looking to partner with Japanese extrusion equipment manufacturers or suppliers, several factors are key to success:

- Reputation and Proven Expertise: Choose companies with longstanding histories and positive track records delivering reliable, quality equipment and services.

- Equipment Fit and Customization: Ensure the manufacturer's machines match your billet size and profile complexity demands. The ability to tailor dies and extrusion parameters is vital for product differentiation.

- Certification and Quality Assurance: Preference should be given to suppliers with ISO 9001 or equivalent certifications, ensuring adherence to internationally accepted manufacturing standards.

- Customer Service and Technical Support: Strong supplier support—including design consultation, installation assistance, and ongoing service—can accelerate time-to-market and reduce operational risks.

- OEM and International Experience: Japanese aluminum extrusion equipment manufacturers and suppliers with extensive OEM and export experience typically provide smoother logistics, comprehensive documentation, and language-capable support, facilitating cross-border collaborations.

Industries Benefiting from Japanese Aluminum Extrusion Equipment

Japanese extrusion technologies support myriad industries globally by enabling lightweight, strong, and intricately shaped aluminum components.

- Automotive and Transportation: Ultramodern extrusions form chassis structures, battery enclosures for electric vehicles, body panels, and heat dissipation components—contributing to improved vehicle efficiency and performance.

- Construction and Architecture: Aluminum profiles for window frames, curtain walls, stairs, and structural reinforcements benefit from Japan's advanced extrusion technology, providing durability and aesthetic appeal.

- Electronics and Consumer Products: Precision housings, LED heat sinks, and compact frameworks for laptops and mobile devices are manufactured with tight tolerances and reliable production repeatability.

- Industrial Machinery and Equipment: Frames, guide rails, conveyor parts, and assembly line components benefit from efficient extrusion combined with machining services provided by Japanese manufacturers.

- Medical Device Components: High-precision extrusions forming casings and structural elements in medical equipment gain from the stringent quality controls standard in Japan.

The Future Outlook for Aluminum Extrusion in Japan

The Japanese aluminum extrusion sector continues to evolve rapidly, responding to emerging demands and leveraging new technologies:

- Sustainability Focus: The emphasis on aluminum recycling and eco-friendly manufacturing processes grows, with suppliers developing closed-loop systems and lightweight, energy-saving extrusions.

- Growing Electric Vehicle Market: Increased uptake of electric and hybrid vehicles spurs demand for advanced aluminum profiles in battery casings, cooling systems, and structural reinforcements.

- Advanced Automation and Robotics: Automated extrusion lines with robotic handling and AI-driven quality inspection are becoming standard to boost productivity and precision.

- Global Market Expansion: Japanese manufacturers are actively expanding export services and adapting to diverse regional specifications, further solidifying their role in global supply chains.

- Materials Innovation: Research into new aluminum alloys with enhanced strength, corrosion resistance, and formability continues, offering customers more options for challenging applications.

Conclusion

Japan remains a global leader in aluminum extrusion equipment manufacturing and supply, driven by a commitment to technical excellence, quality, and innovation. Companies like UACJ Corporation, UBE Machinery, Nikkei MC Aluminium, Asahi Aluminium, and Shibaura Machine exemplify this leadership by offering diversified, high-performance equipment and support services tailored to the needs of OEMs, wholesalers, and manufacturers worldwide.

For businesses seeking reliable, technologically advanced extrusion solutions, partnering with Japanese manufacturers provides access to some of the most refined processes and equipment technologies available today. Their emphasis on customization, precision engineering, and sustainability prepares OEM clients and exporters alike for ongoing industry challenges and market evolution.

Frequently Asked Questions (FAQ)

1. What is the primary advantage of choosing Japanese aluminum extrusion equipment manufacturers and suppliers compared to others?

Japanese manufacturers are globally recognized for precision engineering, reliability, innovative equipment, and stringent quality control—making them ideal for demanding OEM and wholesale needs.

2. Can Japanese suppliers customize aluminum extrusions for unique industrial needs?

Yes. Leading firms like UACJ and UBE provide tailored die design, precision extrusion, finishing options, and supply chain solutions for both domestic and international customers.

3. What certifications do reputable Japanese aluminum extrusion suppliers hold?

Most hold ISO 9001 or higher certifications, guaranteeing adherence to international quality management standards.

4. How does using aluminum extrusion benefit automotive manufacturing?

Aluminum extrusion enables weight reduction, improving fuel efficiency and performance, while offering corrosion resistance and forming flexibility critical for modern vehicles.

5. Are Japanese aluminum extrusion suppliers open to international partnerships and OEM cooperation?

Absolutely. Many focus on export markets and OEM collaborations, offering comprehensive support from prototype development through mass production and reliable global logistics.