Content Menu

● Introduction to Aluminum Extrusion in Spain

● Why Choose Spanish Aluminum Extruder Manufacturers and Suppliers?

● Leading Aluminum Extruder Manufacturers and Suppliers in Spain

>> RAESA

>> AV Alumitran

>> Exlabesa

>> ALUEUROPA

>> Aluminera Extrusion S.A.

>> Extrugasa

>> Inalcom

● Industry Trends and Technologies in Spanish Aluminum Extrusion

>> Automation and Precision Manufacturing

>> Customized Profile Development

>> Sustainability Initiatives

>> Comprehensive Quality Assurance

>> Digitalization and Industry 4.0

● Conclusion

● Frequently Asked Questions (FAQ)

>> Q1: What services do Spanish aluminum extruder manufacturers and suppliers generally provide?

>> Q2: How do Spanish manufacturers ensure quality?

>> Q3: Are Spanish aluminum extruder manufacturers and suppliers capable of OEM and private label services?

>> Q4: What industries benefit most from Spanish aluminum extrusions?

>> Q5: How can I request a custom aluminum extrusion from a Spanish supplier?

Spain has established itself as a key player in the European aluminum extrusion industry, recognized globally for its quality, innovation, and service capabilities. The country boasts a diverse network of aluminum extruder manufacturers and suppliers who excel in delivering complex and customized aluminum profiles tailored to the needs of various sectors such as construction, automotive, energy, and industrial manufacturing. This comprehensive article explores the top aluminum extruder manufacturers and suppliers in Spain, industry trends, innovation, and why Spain is a preferred sourcing destination. Additionally, the article concludes with a detailed FAQ and conclusion to provide further clarity.

Introduction to Aluminum Extrusion in Spain

Aluminum extrusion is a critical manufacturing process whereby aluminum alloys are heated and forced through a shaped die to create profiles of varying cross-sections. These profiles are foundational to a myriad of applications ranging from architectural frameworks, automotive parts, electronic housings, to consumer products. Spain's aluminum extrusion sector is noteworthy for its adherence to quality, sustainable practices, and ability to cater to both local and international markets.

Spanish aluminum extruder manufacturers and suppliers have gained a competitive edge through decades of experience, advanced production capabilities, and a commitment to innovation. Their contribution is vital to industries looking for lightweight, corrosion-resistant, and recyclable material solutions with excellent structural properties.

Why Choose Spanish Aluminum Extruder Manufacturers and Suppliers?

Choosing Spanish aluminum extruder manufacturers and suppliers yields numerous advantages:

- Proven Industry Expertise: Spain boasts companies with decades of operational experience who constantly evolve with the material and process innovations, making them reliable partners for demanding projects.

- Advanced Manufacturing Infrastructure: Spanish extruders utilize modern extrusion presses, automated CNC machining, and rigorous quality control systems compliant with certifications like ISO 9001 to guarantee precision and consistency.

- Customized Solutions: Whether clients require standard profiles or highly specialized and complex shapes, Spanish manufacturers are equipped to provide tailored profiles, surface treatments, and assembly services.

- Global Reach: Many manufacturers support a wide international client base, including OEMs, wholesalers, and product manufacturers, ensuring quality aluminium extrusion products delivered worldwide.

- Commitment to Sustainability: Spain's extrusion industry prioritizes eco-friendly production, employing recycled aluminum, energy-efficient technologies, and waste reduction programs.

- Competitive Pricing and Service: The combination of efficient production, skilled labor, and intelligent logistics strategies allows Spanish suppliers to offer competitive pricing without compromising on quality or delivery times.

Leading Aluminum Extruder Manufacturers and Suppliers in Spain

Spain presents a competitive landscape of aluminum extrusion companies, each known for specific strengths, technical innovation, and customer service focus. Here we highlight the top manufacturers and suppliers:

RAESA

RAESA has over 40 years of history as a leading manufacturer in extruded aluminum profiles. The company specializes in high-complexity profiles and special alloys certified to meet demanding standards for various sectors.

RAESA's facilities include multiple extrusion presses with an annual capacity reaching 30,000 tons across Spain and Argentina. The company supports product development from prototype design to final delivery, ensuring customization and technical consultancy throughout the process.

Core Sectors: Construction, automotive, energy, irrigation, industrial applications

Certifications: ISO 9001:2015

Strengths: Complex profiles, bespoke alloys, advanced finishing

AV Alumitran

With a heritage spanning more than four decades, AV Alumitran is reputed for its innovative approaches and environmental responsibility. The company exports extensively to Europe, Africa, and the Americas, serving architecture, transport, and industrial engineering sectors.

AV Alumitran prides itself on adopting the latest extrusion and surface treatment techniques, including anodizing and powder coating. Customer satisfaction and quality assurance are central to their operational philosophy.

Core Sectors: Architecture, transport, engineering

Geographic Reach: Offices across Europe, Morocco, Central America

Capabilities: Turnkey solutions combining extrusion and finishing services

Exlabesa

Exlabesa integrates extrusion with finished aluminium product manufacturing, delivering complete system solutions tailored to residential and commercial construction projects. Their vertically integrated approach ensures quality control at every stage from extrusion to machining and assembly.

The company emphasizes sustainable manufacturing and logistics to guarantee timely delivery without compromising environmental or quality standards.

Core Specializations: Windows, doors, facades, industrial frameworks

Sustainability Focus: Energy-efficient processes and recycled material use

ALUEUROPA

ALUEUROPA is a family-owned company that combines tradition with innovation by providing a wide range of extrusionrelated services, including thermal break systems, anodizing, vertical coatings, and precise machining.

Their commitment to logistics efficiency and flexibility allows them to meet diverse client demands globally, including custom order volume scalability.

Aluminera Extrusion S.A.

Formed in 2018, Aluminera Extrusion S.A. is a younger but highly dynamic participant focusing on the architectural and industrial sectors. With a notable capacity of 9,000 tons per year, Aluminera emphasizes innovation, quality, and personalized service to develop profiles suitable for specialized applications.

Extrugasa

Extrugasa, an established supplier, contributes significantly to Spain's extrusion output focused on architectural and industrial aluminum profiles. Their extensive experience supports consistent delivery of quality products tailored to demanding construction and manufacturing sectors.

Inalcom

Inalcom has over 20 years of industry experience, specializing in aluminum extrusion technology and consultation. The company offers a range of services including technical guidance and customized extrusion solutions that optimize operational efficiency and product performance.

Industry Trends and Technologies in Spanish Aluminum Extrusion

Spain's aluminum extrusion sector is continuously evolving to embrace new production methodologies, sustainability measures, and market demands. Key trends include:

Automation and Precision Manufacturing

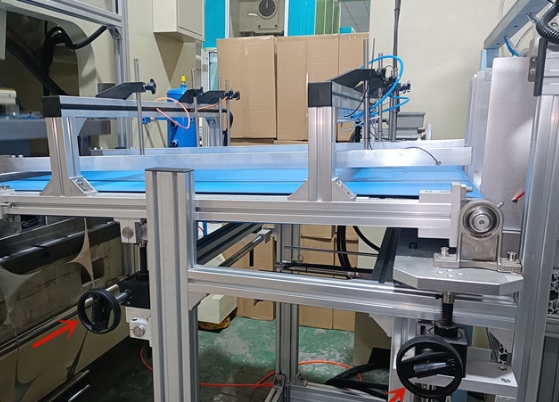

Modern Spanish extrusion plants incorporate automated extrusion presses equipped with advanced control systems for accurate temperature and pressure management. CNC machining centers support precise cutting, milling, drilling, and finishing operations, ensuring tight tolerances and high-quality output.

Customized Profile Development

Manufacturers focus heavily on design collaboration with clients, using CAD software and prototype extrusion testing to create profiles that meet specific functional or aesthetic requirements while optimizing material use.

Sustainability Initiatives

Spanish extruders lead in recycling scrap aluminum and integrating energy-saving technologies in production lines. Many have implemented ISO 14001 environmental management standards and strive to minimize carbon footprints throughout the supply chain.

Comprehensive Quality Assurance

Compliance with international standards such as EN 12020 (aluminum extrusion standards) and ISO 9001 certification forms the backbone of quality control. Dedicated quality departments conduct non-destructive testing, dimensional inspections, and material certifications to ensure product integrity.

Digitalization and Industry 4.0

Industry 4.0 concepts are being integrated with predictive maintenance systems, real-time monitoring of extrusion presses, and supply chain optimization software enhancing production efficiency and responsiveness to customer needs.

Conclusion

Spain's aluminum extrusion industry is marked by a combination of proven expertise, technical innovation, and sustainable practices, making its manufacturers and suppliers an attractive choice for global clients. Companies like RAESA, AV Alumitran, and Exlabesa demonstrate leadership through high-quality processes, customized solutions, and extensive international networks. The strategic focus on automation, quality assurance, and environmentally friendly production makes Spanish aluminum extruders top contenders in the global marketplace. Whether you require standard profiles or complex, custom-designed extrusions, Spain offers reliable partners capable of delivering solutions aligned with evolving industrial needs.

Frequently Asked Questions (FAQ)

Q1: What services do Spanish aluminum extruder manufacturers and suppliers generally provide?

A1: They offer end-to-end services including custom profile design, die and tooling production, extrusion, surface treatments such as anodizing and powder coating, mechanical processing like cutting and machining, and logistics solutions for worldwide delivery.

Q2: How do Spanish manufacturers ensure quality?

A2: Quality is maintained through adherence to international standards like ISO 9001, rigorous in-house testing, certified material traceability, and a robust quality management system at every production stage.

Q3: Are Spanish aluminum extruder manufacturers and suppliers capable of OEM and private label services?

A3: Yes, most leading Spanish extruders provide OEM and private label services for international brands, wholesalers, and manufacturers, offering flexible production runs to meet client specifications.

Q4: What industries benefit most from Spanish aluminum extrusions?

A4: Key industries include construction (windows, doors, facades), automotive, renewable energy, industrial automation, electronics, irrigation, and furniture manufacturing among others.

Q5: How can I request a custom aluminum extrusion from a Spanish supplier?

A5: Customers typically submit detailed product requirements or technical drawings. Manufacturers then provide design support, recommend suitable alloys and profile designs, and guide clients through prototyping to full-scale production.