Content Menu

● Foshan Yejing Machinery Manufacturing Co., Ltd.

>> Company Overview

>>> Key Strengths

>>> Product Highlights

>>> Customer Testimonials

● Wuxi Yuanchang Machinery Co., Ltd.

>> Company Overview

>>> Key Strengths

>>> Product Highlights

● Nanjing Teyun Machinery Manufacture Co., Ltd.

>> Company Overview

>>> Key Strengths

>>> Product Highlights

● Foshan Qisheng Machinery Technology Co., Ltd.

>> Company Overview

>>> Key Strengths

● Enping Huanan Heavy Industrial Technology Co., Ltd.

>> Company Overview

>>> Key Strengths

● Jiangsu Giant Ally Imp.&Exp.Co., Ltd.

>> Company Overview

>>> Key Strengths

● Jiangyin Royal Machinery Equipment Co., Ltd.

>> Company Overview

>>> Key Strengths

● Chengdu Zhengxi Intelligent Equipment Group Co., Ltd.

>> Company Overview

>>> Key Strengths

● Foshan Dynamax Industry Co., Ltd.

>> Company Overview

>>> Key Strengths

● Guangdong Xingfa Aluminium Co., Ltd.

>> Company Overview

>>> Key Strengths

● The Aluminum Extrusion Process: How It Works

● Industry Trends and Market Insights

● Technological Innovations

● OEM Services and Customization

● Quality Control and Certifications

● Environmental and Energy Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical temperature range for preheating aluminum billets in extrusion?

>> 2. How often should maintenance be performed on an aluminum extrusion press?

>> 3. What causes surface defects in extruded aluminum profiles?

>> 4. How can productivity be improved during the extrusion process?

>> 5. What are the main advantages of working with Chinese aluminum extrusion press manufacturers?

China has firmly established itself as the global powerhouse in the aluminum extrusion industry, producing a significant portion of the world's aluminum profiles and extrusion equipment. Aluminum extrusion presses are the backbone of this sector, enabling the transformation of raw aluminum billets into intricate profiles used across construction, automotive, aerospace, electronics, and countless other industries. For international brands, wholesalers, and manufacturers seeking OEM solutions, partnering with a reputable Chinese aluminum extrusion press manufacturer is a strategic choice for quality, innovation, and cost-effectiveness.

Foshan Yejing Machinery Manufacturing Co., Ltd.

Company Overview

Founded in 1990, Foshan Yejing Machinery Manufacturing Co., Ltd. is a premier manufacturer specializing in the design and production of aluminum extrusion presses and complete extrusion production lines. With more than 3,000 sets of aluminum profile extruders manufactured and exported to over 30 countries—including Australia, South Korea, Turkey, and Brazil—Yejing commands a leading position in both domestic and international markets.

Key Strengths

- Extensive Experience: Over three decades of expertise in aluminum extrusion press manufacturing.

- Global Reach: Exported over 200 sets of presses worldwide.

- Innovation: Pioneers in intelligent extrusion production lines and new short-stroke presses.

- Quality Assurance: Supplies to leading Chinese aluminum profile companies such as Xingfa Aluminum, Nanping Aluminum, and Xinhe Aluminum.

- OEM/ODM Capability: Provides complete OEM solutions for overseas brands and manufacturers.

Product Highlights

- Intelligent extrusion production lines for high efficiency.

- New type short-stroke presses for energy savings and precision.

- Customizable technical parameters to meet diverse client requirements.

Customer Testimonials

> “Yejing's presses are robust, reliable, and deliver consistent quality. Their after-sales support is exceptional, making them our preferred supplier for aluminum extrusion equipment.”

Wuxi Yuanchang Machinery Co., Ltd.

Company Overview

Wuxi Yuanchang Machinery Co., Ltd. is a major player in the aluminum extrusion press market, known for its advanced manufacturing facilities and robust R&D capabilities. Based in Wuxi, Jiangsu province, the company offers a wide range of extrusion presses, including heavy-duty models for industrial applications.

Key Strengths

- Diverse Product Line: Offers extrusion presses with capacities from 600T to over 3600T.

- Customization: Provides OEM and ODM services for global clients.

- Quality Components: Utilizes high-grade steel, PLC control systems, and international brand parts.

Product Highlights

- High efficiency and low energy consumption.

- Automated operation with touch screen integration.

- Exported to Europe, Middle East, and Southeast Asia.

Nanjing Teyun Machinery Manufacture Co., Ltd.

Company Overview

Nanjing Teyun Machinery Manufacture Co., Ltd. is renowned for its comprehensive range of aluminum extrusion lines and presses. The company emphasizes technological innovation and precision engineering, serving both domestic and international markets.

Key Strengths

- Integrated Solutions: Offers complete extrusion lines, including coating and shearing equipment.

- Advanced R&D: Focuses on continuous improvement and process automation.

- Global Service: Strong export record and after-sales support.

Product Highlights

- Hydraulic extrusion presses with advanced safety features.

- High-speed, high-precision operation for demanding applications.

Foshan Qisheng Machinery Technology Co., Ltd.

Company Overview

Located in Foshan, Guangdong, Foshan Qisheng Machinery Technology Co., Ltd. specializes in aluminum extrusion machines and related parts. Their presses are widely recognized for their reliability and performance in the production of aluminum profiles.

Key Strengths

- Comprehensive Product Range: Offers extrusion presses, puller machines, and billet heating systems.

- Customization: Tailors solutions for various industrial needs.

- Efficient Production: Automated lines for consistent output.

Enping Huanan Heavy Industrial Technology Co., Ltd.

Company Overview

Enping Huanan Heavy Industrial Technology Co., Ltd. is a reputable manufacturer of aluminum extrusion equipment, including billet heating machines and profile pullers. Based in Jiangmen, Guangdong, the company is known for its rapid response and technical expertise.

Key Strengths

- Fast Delivery: Quick response times and efficient order fulfillment.

- Specialized Equipment: Focus on billet heating and extrusion support machinery.

Jiangsu Giant Ally Imp.&Exp.Co., Ltd.

Company Overview

Jiangsu Giant Ally Imp.&Exp.Co., Ltd. provides a full suite of aluminum extrusion dies, presses, and quenching systems. Their products are recognized for quality and innovation, serving both domestic and international customers.

Key Strengths

- Comprehensive Solutions: From dies to complete extrusion lines.

- Strong R&D: Continuous product improvement and technological upgrades.

Jiangyin Royal Machinery Equipment Co., Ltd.

Company Overview

Jiangyin Royal Machinery Equipment Co., Ltd. specializes in the design and production of extrusion dies and presses. The company's focus on precision engineering and quality control has earned it a solid reputation in the industry.

Key Strengths

- Precision Manufacturing: High-quality extrusion dies and presses.

- Global Exports: Supplies to clients in Europe, Asia, and the Americas.

Chengdu Zhengxi Intelligent Equipment Group Co., Ltd.

Company Overview

Chengdu Zhengxi Intelligent Equipment Group Co., Ltd. is an innovative manufacturer of hydraulic presses, including aluminum extrusion presses. The company leverages intelligent manufacturing systems for enhanced productivity and quality.

Key Strengths

- Smart Manufacturing: Integration of automation and data analytics.

- Wide Product Range: Hydraulic presses for various industrial applications.

Foshan Dynamax Industry Co., Ltd.

Company Overview

Foshan Dynamax Industry Co., Ltd. focuses on aluminum extrusion handling systems and automation solutions. Their products support efficient extrusion operations and are widely used in modern extrusion plants.

Key Strengths

- Automation Expertise: Advanced handling and quenching systems.

- Industry Partnerships: Works with leading aluminum profile manufacturers.

Guangdong Xingfa Aluminium Co., Ltd.

Company Overview

Founded in 1984, Guangdong Xingfa Aluminium Co., Ltd. is one of China's largest and most respected aluminum profile manufacturers. While primarily known for its finished profiles, Xingfa also operates advanced extrusion presses and contributes significantly to industry innovation.

Key Strengths

- Industry Leadership: Pioneer in architectural and industrial aluminum products.

- Technological Innovation: Invests heavily in R&D and intelligent manufacturing.

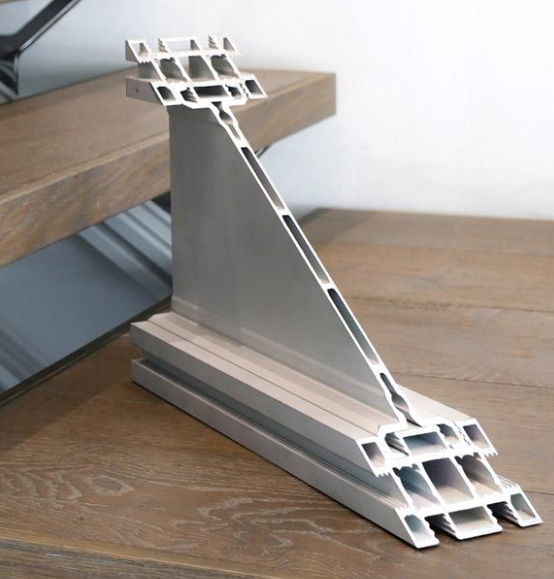

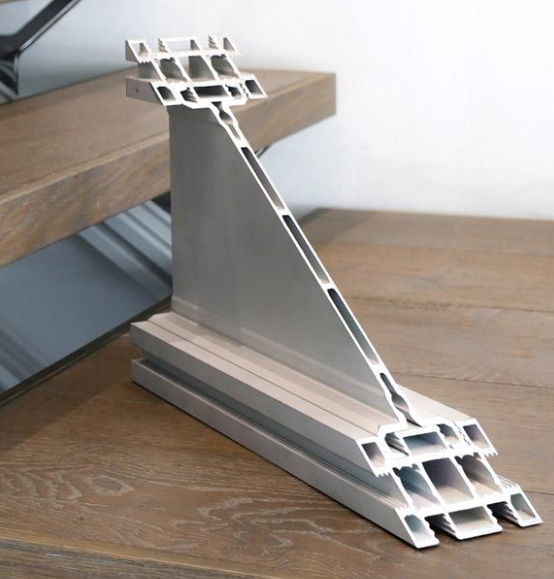

The Aluminum Extrusion Process: How It Works

To better understand the importance of high-quality extrusion presses, let's briefly review the aluminum extrusion process:

1. Die Preparation: The die is designed and preheated to ensure smooth aluminum flow.

2. Billet Preheating: Aluminum billets are heated to 700–930°F (370–500°C), enhancing malleability.

3. Extrusion: A hydraulic ram applies pressure, forcing the billet through the die to form the desired profile.

4. Cooling: The extruded profile is cooled by air or water.

5. Cutting and Stretching: The profile is cut to length and stretched to correct any deformation.

6. Aging and Finishing: The extruded aluminum may be heat-treated, anodized, or painted for enhanced properties.

Industry Trends and Market Insights

The aluminum extrusion industry in China has witnessed remarkable growth over the past decade, driven by increasing demand from sectors such as construction, automotive, aerospace, and electronics. Manufacturers have been investing heavily in research and development to enhance the efficiency, precision, and environmental sustainability of extrusion presses.

One notable trend is the adoption of intelligent manufacturing systems, which integrate automation, data analytics, and IoT technologies to optimize production processes. These advancements not only improve product quality but also reduce energy consumption and operational costs.

Furthermore, Chinese manufacturers are expanding their global footprint by establishing partnerships and service centers in key international markets. This global expansion ensures timely support and customization for overseas clients, reinforcing China's position as a preferred supplier.

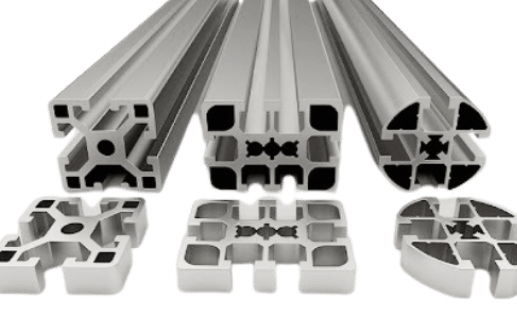

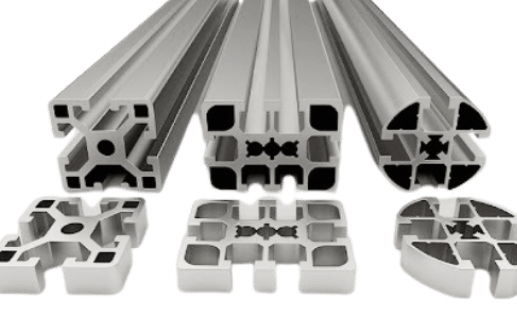

Technological Innovations

Technological innovation remains a cornerstone of China's aluminum extrusion press industry. Companies are developing new press designs that offer shorter stroke lengths, higher pressing speeds, and enhanced precision. These innovations cater to the evolving needs of customers who require complex and high-tolerance aluminum profiles.

In addition, the integration of hydraulic and electric drive systems has led to more energy-efficient presses. These hybrid systems combine the power of hydraulics with the precision of electric controls, resulting in improved performance and reduced environmental impact.

OEM Services and Customization

OEM services are a significant aspect of the Chinese aluminum extrusion press market. Manufacturers offer tailored solutions to meet the specific requirements of international brands, wholesalers, and producers. Customization options include press capacity, automation level, control systems, and auxiliary equipment.

This flexibility allows clients to optimize their production lines for various aluminum alloys and profile designs, enhancing competitiveness in their respective markets.

Quality Control and Certifications

Quality assurance is paramount in the aluminum extrusion press industry. Leading Chinese manufacturers implement rigorous quality control measures throughout the production process, from raw material selection to final assembly and testing.

Many companies have obtained international certifications such as ISO 9001, CE, and SGS, demonstrating their commitment to meeting global standards. These certifications provide confidence to overseas buyers regarding product reliability and safety.

Environmental and Energy Considerations

Sustainability is increasingly important in manufacturing. Chinese aluminum extrusion press manufacturers are adopting eco-friendly practices, including energy-efficient press designs, waste reduction, and recycling initiatives.

The development of presses with lower energy consumption aligns with global efforts to reduce carbon footprints and comply with environmental regulations.

Conclusion

China's aluminum extrusion press manufacturers are at the forefront of industry innovation, quality, and global service. Their commitment to technological advancement, customization, and sustainability makes them ideal partners for international brands and manufacturers seeking reliable and efficient extrusion solutions. By leveraging advanced manufacturing, stringent quality control, and robust OEM/ODM support, these companies continue to shape the future of the global aluminum extrusion industry.

Frequently Asked Questions

1. What is the typical temperature range for preheating aluminum billets in extrusion?

Aluminum billets are usually preheated to between 700°F and 930°F (370°C to 500°C), depending on the alloy and press requirements.

2. How often should maintenance be performed on an aluminum extrusion press?

Routine maintenance should be conducted regularly, with hydraulic systems, dies, and moving parts checked daily or weekly, and comprehensive inspections scheduled monthly or quarterly.

3. What causes surface defects in extruded aluminum profiles?

Surface defects can result from improper die preparation, billet contamination, incorrect extrusion temperatures, or insufficient lubrication.

4. How can productivity be improved during the extrusion process?

Implementing data analytics, optimizing die design, maintaining equipment, and using automation can significantly enhance productivity.

5. What are the main advantages of working with Chinese aluminum extrusion press manufacturers?

Chinese manufacturers offer competitive pricing, advanced technology, large-scale production, and robust OEM/ODM support, making them ideal partners for global brands and manufacturers.