Content Menu

● Introduction to the Redrex Upgraded Aluminum Bowden Extruder

>> Key Features

● Installation Process

● Benefits of the Redrex Upgraded Aluminum Bowden Extruder

>> Improved Durability

>> Enhanced Filament Control

>> Better Support for Flexible Filaments

>> Print Quality Improvement

● Comparison with Other Upgrades

>> Direct Drive Conversion Kits

>> Dual-Gear Extruders

>> MK8 Extruder Kits

● User Feedback and Reviews

● Price and Value

● Common Issues and Solutions

● Conclusion

● FAQs

>> 1. What are the main benefits of using the Redrex Upgraded Aluminum Bowden Extruder?

>> 2. Is the Redrex extruder compatible with my Ender 3 V2?

>> 3. How difficult is the installation process?

>> 4. Can I use the Redrex extruder for printing flexible filaments like TPU?

>> 5. Is the Redrex extruder worth the investment compared to other upgrades?

● Citations:

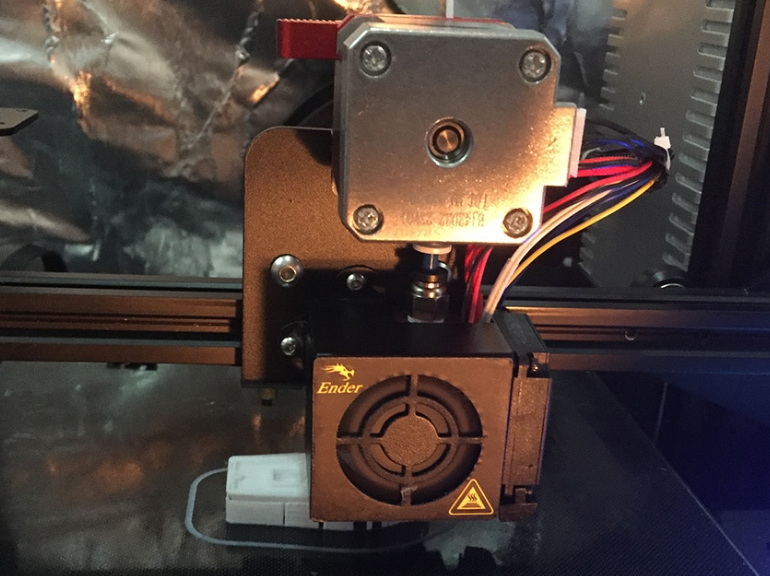

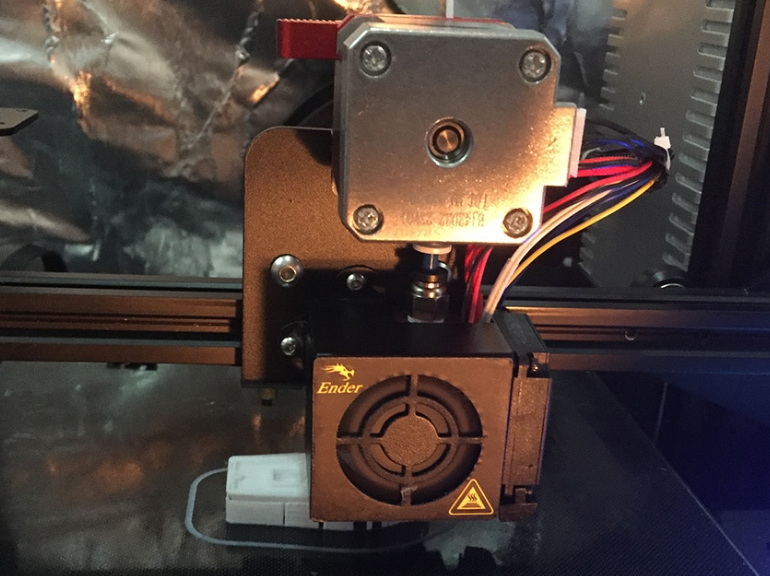

The Redrex Upgraded Aluminum Bowden Extruder is a popular upgrade for various 3D printers, including the Ender 3 series and CR-10 models. This article will delve into the details of this extruder, exploring its features, installation process, benefits, and whether it is worth the investment for your 3D printing needs.

Introduction to the Redrex Upgraded Aluminum Bowden Extruder

The Redrex Upgraded Aluminum Bowden Extruder is designed to enhance the performance of your 3D printer by providing a more robust and reliable filament feeding system. Unlike the stock plastic extruders, which can be prone to breaking and may not handle certain types of filaments well, the Redrex extruder offers improved durability and control.

Key Features

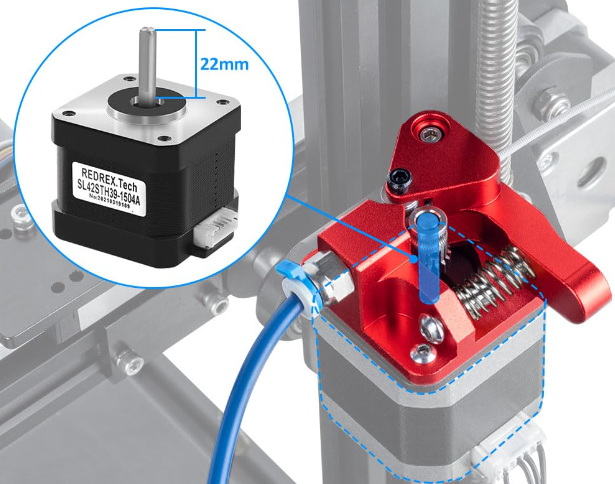

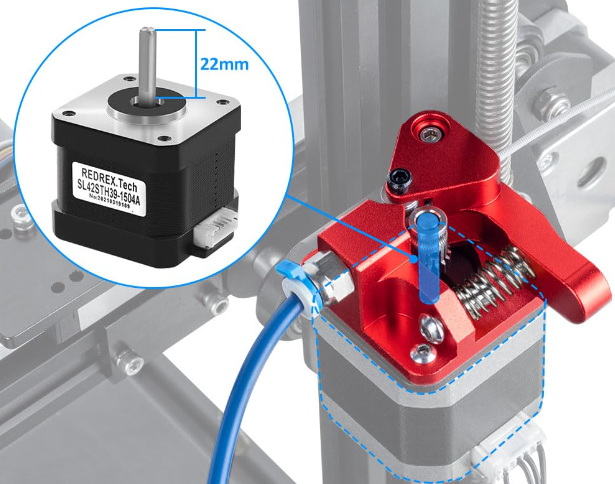

- Material: Made from high-quality aluminum, this extruder is more durable than its plastic counterparts.

- Design: It includes a spring-adjustable feeder, which helps in maintaining consistent tension on the filament, reducing issues like skipping or grinding.

- Compatibility: Compatible with a range of 3D printers, including the Ender 3 V2, Ender 3 Pro, Ender 5, and CR-10 series.

- Drive Gear: Features a 40-teeth MK8 drive gear for smooth filament feeding, enhancing print quality and reliability.

Installation Process

Installing the Redrex Upgraded Aluminum Bowden Extruder is generally straightforward, though some users may find it slightly challenging due to the lack of detailed instructions. Here's a simplified overview of the steps involved:

1. Remove the Old Extruder: Start by disconnecting and removing the existing extruder from your printer.

2. Mount the New Extruder: Attach the Redrex extruder to the printer frame using the provided screws and mounts.

3. Adjust the Feeder: Adjust the spring tension to ensure proper filament grip without causing excessive pressure.

4. Connect the Bowden Tube: Securely connect the Bowden tube to both the extruder and the hotend.

For a more detailed guide, you can refer to instructional videos available online. These videos often provide step-by-step instructions and can be invaluable for those new to 3D printer upgrades.

Benefits of the Redrex Upgraded Aluminum Bowden Extruder

Improved Durability

The aluminum construction of the Redrex extruder makes it significantly more durable than the stock plastic extruders. This means less worry about it breaking during use, especially when handling more demanding filaments. Customers have praised its sturdy and solid construction, noting that it should last the lifetime of the printer[1].

Enhanced Filament Control

The spring-adjustable feeder allows for precise control over filament tension, reducing issues like filament skipping or grinding. This results in more consistent and reliable prints. Users have reported improvements in print quality, with fewer filament feed issues[1].

Better Support for Flexible Filaments

The Redrex extruder is well-suited for printing flexible filaments, such as TPU, due to its ability to maintain consistent tension and prevent filament deformation. This makes it an excellent choice for projects requiring flexible materials.

Print Quality Improvement

Customers are overwhelmingly positive about the print quality improvement after upgrading to the Redrex extruder. The stiffer bed springs and adjustable feeder have resolved filament feed issues and improved overall print quality for most users[1].

Comparison with Other Upgrades

Direct Drive Conversion Kits

Another popular upgrade is the direct drive conversion kit, which eliminates the need for a Bowden tube altogether. While this setup can offer better performance for flexible filaments and reduce retraction issues, it adds weight to the print head, potentially causing vibration problems. However, for users who prioritize speed and flexibility, direct drive systems might be more appealing.

Dual-Gear Extruders

Dual-gear extruders provide additional grip on the filament, reducing slipping and grinding. However, they can be more expensive and may require adjustments to the printer's settings. Some users recommend dual-gear extruders for enhanced performance, especially for those who frequently print with flexible filaments[4].

MK8 Extruder Kits

The MK8 Extruder Kit is another option for upgrading your 3D printer's extruder. It offers stable and durable performance, supporting both flexible and regular filaments. The kit is easy to install and includes all necessary parts for assembly. It allows for faster printing with sustained quality and reduces the risk of grinding the filament[3].

User Feedback and Reviews

Customer feedback on the Redrex extruder is generally positive, with users praising its build quality and ease of installation. While some have noted that the instructions could be clearer, most found the process straightforward and were able to find helpful resources online. The extruder's ability to resolve filament feed issues and improve print quality has made it a highly recommended upgrade for many users[1].

Some users have noted that the extruder is priced similarly to dual-gear models, which might be a drawback for those seeking more advanced features[1]. However, for its price, the Redrex extruder provides excellent value, offering significant improvements over stock extruders.

Price and Value

The Redrex extruder is priced competitively, offering excellent value for its quality and performance. Some users have noted that it is a bit pricey compared to other non-dual-gear options, but the benefits it provides justify the cost for many. The extruder's durability and reliability make it a worthwhile investment for those seeking to enhance their printing experience[1].

Common Issues and Solutions

While the Redrex extruder is generally reliable, some users have reported issues with filament feeding due to excessive spring tension. This can be resolved by adjusting the spring to a lower tension setting, ensuring that the filament is not crushed or deformed[5].

Additionally, some users have noted that the extruder may introduce more friction in the Bowden tube, which can affect print quality. This can often be mitigated by ensuring that the Bowden tube is properly secured and that there are no kinks or blockages[7].

Conclusion

The Redrex Upgraded Aluminum Bowden Extruder is a solid choice for those looking to enhance their 3D printing experience. It offers improved durability, better filament control, and support for flexible filaments. While it may not be as advanced as some other upgrades like dual-gear extruders, it provides excellent value for its price.

FAQs

1. What are the main benefits of using the Redrex Upgraded Aluminum Bowden Extruder?

The main benefits include improved durability, enhanced filament control, and better support for flexible filaments.

2. Is the Redrex extruder compatible with my Ender 3 V2?

Yes, the Redrex extruder is compatible with the Ender 3 V2, as well as other models like the Ender 3 Pro and CR-10 series.

3. How difficult is the installation process?

The installation is generally straightforward, but some users may find it challenging due to the lack of detailed instructions. Online tutorials can be helpful.

4. Can I use the Redrex extruder for printing flexible filaments like TPU?

Yes, the Redrex extruder is well-suited for printing flexible filaments due to its ability to maintain consistent tension.

5. Is the Redrex extruder worth the investment compared to other upgrades?

The Redrex extruder offers excellent value for its price, providing significant improvements over stock extruders. However, for those seeking advanced features like dual-gear setups, other options might be more suitable.

Citations:

[1] https://www.fakespot.com/product/redrex-metal-bowden-extruder-upgrade-spring-adjustable-feeder-with-bowden-tube-and-springs-for-creality-ender-3-v2-ender-3-pro-ender-5-cr10-3d-printers-right-hand-version

[2] https://www.youtube.com/watch?v=fT91Oj2RUDk

[3] https://novo3d.in/mk8-extruder/

[4] https://www.reddit.com/r/ender3/comments/12wypvf/has_anyone_had_problems_with_this_type_of_extruder/

[5] https://www.fakespot.com/product/redrex-metal-bowden-extruder-upgraded-tension-adjustable-for-ender-3-v2-ender-3-pro-cr-10-series-and-other-reprap-prusa-3d-printers-right-hand

[6] https://www.youtube.com/watch?v=QnrH2Sk7y40

[7] https://www.reddit.com/r/ender3v2/comments/149wfud/metal_extruder_upgrade/

[8] https://3dprintinguk.com/review-redrex-dual-gear-extruder/

[9] https://www.youtube.com/watch?v=SoF2AjzrLdg

[10] https://www.youtube.com/watch?v=zJRxRVN3p3Y

[11] https://www.ubuy.co.in/product/10J15ENG-redrex-upgraded-aluminum-bowden-extruder-with-40-teeth-mk8-drive-gear-for-creality-cr-10-series-ende