Content Menu

● Introduction to the CHPower CR-10 Extruder Upgrade

>> Key Features of the Upgrade

● Installing the CHPower CR-10 Extruder Upgrade

>> Tools Required

● Benefits of the Upgrade

>> Improved Print Quality

>> Durability

>> Compatibility

● Comparison with Other Upgrades

>> Dual Extruder Upgrades

>> Direct Drive Extruders

● Advanced Upgrades for Enhanced Performance

>> Direct Drive Conversion

>> Cooling Upgrades

● Troubleshooting Common Extruder Issues

● Upgrading Other Models: CR10 Smart and Ender Series

>> CR10 Smart Extruder Upgrade

>> Ender Series Upgrades

● Conclusion

● FAQs

>> 1. What are the benefits of using an all-metal extruder?

>> 2. Is the CHPower CR-10 extruder upgrade compatible with other Creality printers?

>> 3. How difficult is the installation process?

>> 4. Can I use this upgrade with a dual extruder setup?

>> 5. Are there any specific maintenance tips for the all-metal extruder?

● Citations:

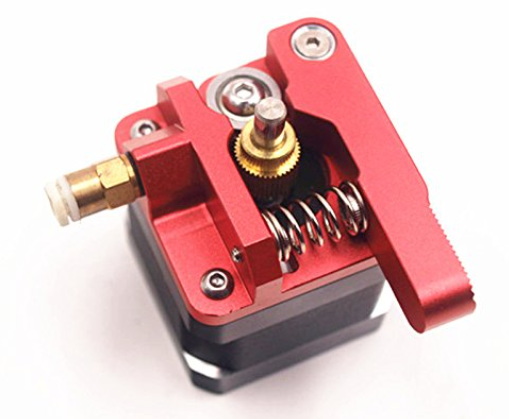

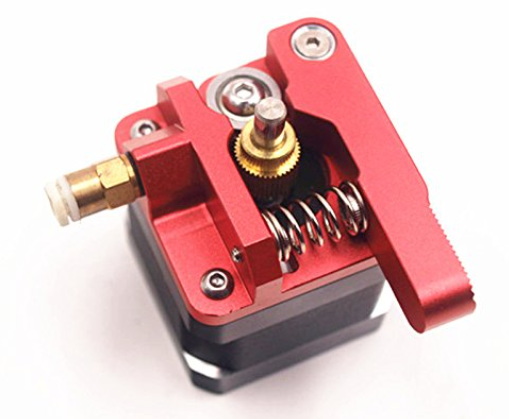

The CHPower CR-10 extruder upgrade is a popular modification for enhancing the performance of Creality's CR-10 series 3D printers. This upgrade involves replacing the stock extruder with an aluminum MK8 drive feed system, which promises improved durability and print quality. In this article, we will explore whether this upgrade is worth considering for your 3D printing needs.

Introduction to the CHPower CR-10 Extruder Upgrade

The CHPower CR-10 extruder upgrade is designed to address common issues with the stock extruder, such as under-extrusion and wear over time. The upgrade features an all-metal construction, which provides better heat dissipation and filament handling compared to the plastic components of the original extruder.

Key Features of the Upgrade

- All-Metal Construction: The aluminum MK8 extruder is more durable and resistant to wear compared to the stock plastic extruder.

- Improved Heat Dissipation: Better heat management helps in maintaining consistent extrusion temperatures, which is crucial for printing with various materials.

- Enhanced Filament Handling: The MK8 system is known for its reliable grip on the filament, reducing issues like slipping or jamming.

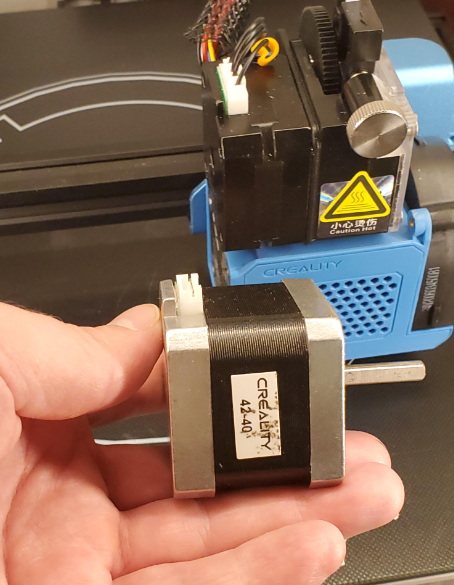

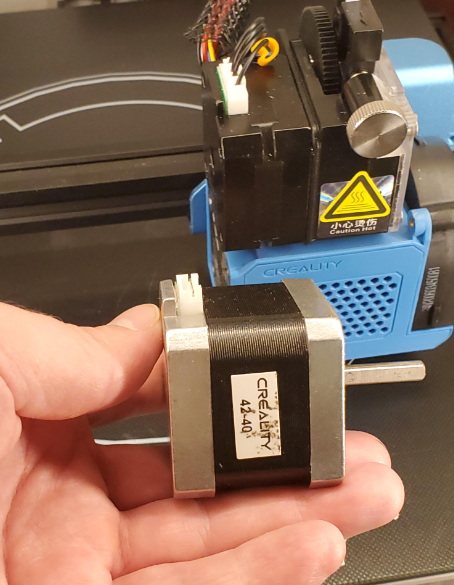

Installing the CHPower CR-10 Extruder Upgrade

Installing the CHPower CR-10 extruder upgrade involves several steps that require basic tools and some technical knowledge. Here's a simplified guide:

1. Prepare the Printer: Ensure the printer is turned off and any filament is unloaded from the extruder.

2. Remove the Stock Extruder: Use Allen wrenches to remove the screws holding the stock extruder in place. Carefully disconnect any electrical connections.

3. Install the New Extruder: Mount the aluminum extruder using the same screws. Ensure all connections are secure and properly aligned.

4. Adjust and Test: Adjust the extruder tension and test the printer to ensure smooth operation.

Tools Required

- Allen wrenches (1.5, 2, 2.5, and 3 mm)

- Needle-nose pliers (optional)

Benefits of the Upgrade

Improved Print Quality

The CHPower CR-10 extruder upgrade can significantly enhance print quality by providing more consistent extrusion. This is particularly beneficial for printing with materials that require precise temperature control, such as PETG or ABS.

Durability

The all-metal design of the MK8 extruder is more resistant to wear and tear compared to the stock plastic extruder. This means fewer replacements and less downtime for maintenance.

Compatibility

The upgrade is compatible with the CR-10 series, including the CR-10, CR-10 Mini, CR-10S, and CR-10 Plus. It can also be used on other Creality models like the Ender 3 and Ender 5 series.

Comparison with Other Upgrades

Dual Extruder Upgrades

For users interested in more advanced features, dual extruder upgrades are available. These allow for printing with two different materials simultaneously, which can be useful for complex prints requiring support structures or multi-color designs. Upgrading to a dual extruder setup involves additional hardware, such as a new motherboard (e.g., MKS or GT2560), and requires software modifications using firmware like Marlin[1].

Direct Drive Extruders

Direct drive extruders, like the Titan or BMG, offer improved performance by reducing the distance between the extruder and the hotend. This setup can enhance print quality and reduce retraction issues. The Micro-Swiss direct drive extruder is particularly popular for its reliability and ability to handle flexible filaments like TPU[3].

Advanced Upgrades for Enhanced Performance

Direct Drive Conversion

Converting your CR-10 to a direct drive setup can significantly improve print quality, especially with flexible materials. However, this requires careful calibration and adjustment of firmware settings to ensure optimal performance[4].

Cooling Upgrades

Adding better cooling systems, such as a Noctua fan or custom fan ducts, can enhance the printer's ability to handle high-temperature materials like ABS or PETG. This is particularly useful when upgrading to a direct drive extruder[6].

Troubleshooting Common Extruder Issues

Common issues with the stock extruder include under-extrusion, over-extrusion, and filament jams. These can often be resolved by adjusting the extruder tension, ensuring proper filament alignment, and maintaining clean and well-lubricated components[5].

Upgrading Other Models: CR10 Smart and Ender Series

CR10 Smart Extruder Upgrade

The CR10 Smart, like other models in the series, can benefit from upgrading to an all-metal extruder. The MK8 extruder is a popular choice for its durability and ease of maintenance. However, users may also consider direct drive upgrades for enhanced performance with flexible filaments[8].

Ender Series Upgrades

The Ender 3 and Ender 5 series can also benefit from extruder upgrades. The process is similar to the CR-10, with the option to install direct drive or dual extruder setups for advanced printing capabilities[2][3].

Conclusion

The CHPower CR-10 extruder upgrade is a worthwhile investment for anyone looking to improve the reliability and performance of their CR-10 series printer. While it may not address all potential issues, such as the need for a dual extruder or direct drive setup, it offers a cost-effective solution for enhancing print quality and durability.

FAQs

1. What are the benefits of using an all-metal extruder?

The all-metal extruder provides better heat dissipation and durability compared to plastic extruders, reducing issues like under-extrusion and wear over time.

2. Is the CHPower CR-10 extruder upgrade compatible with other Creality printers?

Yes, the upgrade is compatible with several Creality models, including the Ender 3 and Ender 5 series, in addition to the CR-10 series.

3. How difficult is the installation process?

The installation requires basic tools and some technical knowledge. It involves removing the stock extruder and mounting the new one, which can be done with careful attention to detail.

4. Can I use this upgrade with a dual extruder setup?

While the CHPower upgrade is designed for single extruders, you can explore dual extruder setups using different components and configurations, such as the MKS or GT2560 boards for dual extrusion.

5. Are there any specific maintenance tips for the all-metal extruder?

Regularly check and adjust the extruder tension to ensure smooth filament flow. Also, keep the extruder clean and free from debris to maintain optimal performance.

Citations:

[1] https://www.instructables.com/How-to-Upgrade-CR-10-From-Single-Extruder-to-Dual-/

[2] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[3] https://www.3djake.com/reviews/micro-swiss/direct-drive-extruder-for-creality-cr-10-ender-3

[4] https://www.youtube.com/watch?v=Li8rmcAJqYI

[5] https://www.youtube.com/watch?v=cAPN7_vF_Ss

[6] https://www.reddit.com/r/Creality/comments/13sj3kv/cr10_smart_extruder_upgrade_options/

[7] https://www.youtube.com/watch?v=7rABznITELA

[8] https://yarkspirifantasyart.com/cr10-smart-extruder-upgrade/

[9] https://www.youtube.com/watch?v=97MSypP6TeQ

[10] https://forum.creality.com/t/cr-10s-extruder-trouble/9680

[11] https://www.rocketryforum.com/threads/updates-needed-for-an-old-workhorse-cr-10s.176416/

[12] https://www.youtube.com/watch?v=eEbCP4NDdkQ

[13] https://www.fakespot.com/product/chpower-cr-10-extruder-upgraded-replacement-aluminum-mk8-drive-feed-3d-printer-extruders-for-creality-cr-10-cr-10s-cr-10-s4-cr-10-s5-reprap-prusa-i3-1-75mm

[14] https://www.youtube.com/watch?v=dYzlqzGcqbc

[15] https://www.youtube.com/watch?v=7tCxO17XZtw

[16] https://www.youtube.com/watch?v=OfAJsjgttCs

[17] https://www.ubuy.com.gh/product/2F7RS81K-chpower-creality-cr-10-hotend-assembly-mk8-extruder-original-replacement-for-cr10-cr-10s-cr-10s400-c

[18] https://www.reddit.com/r/CR10/comments/13ez779/cr10_v2_which_extruders_can_we_upgrade_to/

[19] https://technologiehub.at/project-posts/ultimate-cr-10-3d-printer-upgrades/

[20] https://www.reddit.com/r/CR10/comments/qpgc4n/cr10_max_extruder_problem/