Content Menu

● Introduction to Plastic Extrusion Equipment

>> How Plastic Extrusion Works

>> Advantages of Plastic Extrusion

● Buying Plastic Extrusion Equipment

>> Advantages of Buying

>> Disadvantages of Buying

>> Cost Considerations

● Leasing Plastic Extrusion Equipment

>> Advantages of Leasing

>> Disadvantages of Leasing

>> Leasing Options

● Choosing the Right Option

>> Factors to Consider

>> Strategic Planning

● Additional Considerations

>> Facility Costs

>> Utility and Maintenance Costs

>> Environmental Impact

● Case Studies

>> Example of Leasing Success

>> Example of Buying Success

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of leasing plastic extrusion equipment?

>> 2. How does buying plastic extrusion equipment compare to leasing in terms of long-term costs?

>> 3. What factors should I consider when choosing between buying and leasing plastic extrusion equipment?

>> 4. Can leasing help companies stay up-to-date with the latest technology in plastic extrusion?

>> 5. Are there any tax advantages to leasing plastic extrusion equipment?

● Citations:

When considering how to acquire plastic extrusion equipment for your factory, the decision between buying and leasing can be complex. Both options have their advantages and disadvantages, which depend on your business needs, financial situation, and production requirements. In this article, we will explore the benefits and drawbacks of each option to help you make an informed decision.

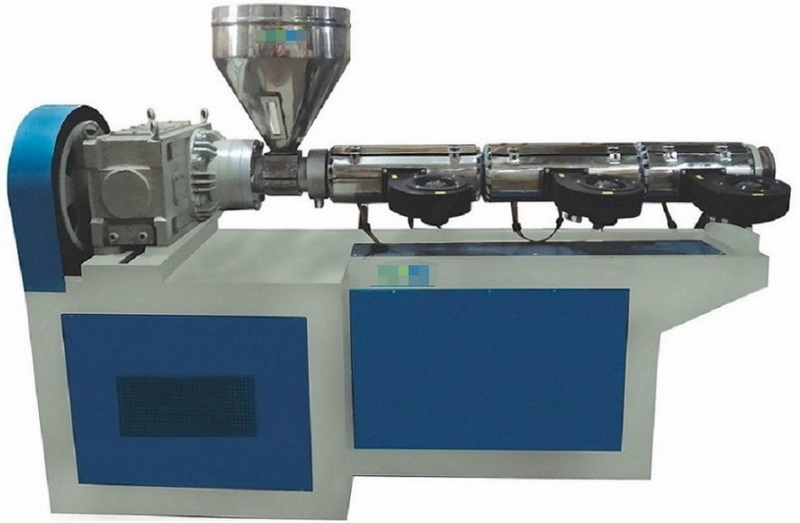

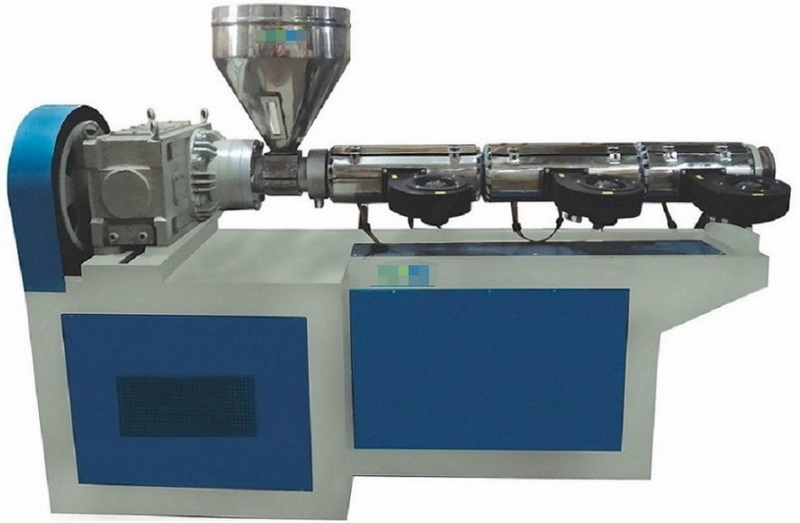

Introduction to Plastic Extrusion Equipment

Plastic extrusion is a widely used process in the plastic industry, known for its efficiency and cost-effectiveness. It involves transforming thermoplastic materials into various shapes and forms, such as pipes, tubes, profiles, and sheets. The process is continuous, allowing for high-volume production with minimal waste.

How Plastic Extrusion Works

The plastic extrusion process begins with feeding raw plastic materials into a hopper, which are then melted and formed into a continuous profile. This process involves several key components:

1. Extruder: The heart of the extrusion line, responsible for melting and forming the plastic.

2. Die: Shapes the molten plastic into the desired form.

3. Cooling System: Cools the extruded product to solidify it.

4. Haul-off System: Pulls the product away from the die at a controlled speed.

Advantages of Plastic Extrusion

Plastic extrusion offers several advantages that make it a popular choice for manufacturing various products:

- Efficiency: Plastic extrusion allows for continuous, high-speed production, leading to improved efficiency and higher output rates[1].

- Versatility: This process can be used to create a wide range of shapes and sizes, from simple tubing to complex profiles[1].

- Consistency: Extrusion generally yields products with consistent cross-sections and quality, ensuring uniformity in every piece produced[1].

- Cost-effectiveness: Due to the high-volume, continuous nature of the process, plastic extrusion is typically more cost-effective than other plastic manufacturing methods[1].

- Material Utilization: Extrusion allows for almost 100% material utilization, as any excess or scrap material can be re-extruded, reducing waste[1].

- Resilience: Extruded plastics are known for their strength and durability, allowing for the creation of products that can withstand various environmental conditions[1].

Buying Plastic Extrusion Equipment

Buying plastic extrusion equipment involves a significant upfront investment. This option is suitable for companies with stable production needs and the financial resources to cover the initial cost.

Advantages of Buying

1. Ownership: Once purchased, the equipment belongs to your company, allowing for long-term use and customization.

2. Cost Savings Over Time: Although the initial cost is high, owning the equipment can lead to savings in the long run, as there are no ongoing lease payments[5].

3. Customization: You have full control to modify or upgrade the equipment as needed.

Disadvantages of Buying

1. High Initial Cost: Requires a substantial upfront investment, which can strain cash flow.

2. Maintenance Costs: You are responsible for all maintenance and repair costs.

3. Obsolescence Risk: Technology advances quickly, and equipment can become outdated.

Cost Considerations

The cost of purchasing plastic extrusion equipment can vary widely depending on the type and size of the equipment. Generally, a complete extrusion line can range from tens of thousands to hundreds of thousands of dollars[3]. Additionally, there are ongoing costs for maintenance, utilities, and potential upgrades.

Leasing Plastic Extrusion Equipment

Leasing offers a flexible alternative to buying, allowing companies to acquire plastic extrusion equipment without a large upfront payment.

Advantages of Leasing

1. Lower Initial Costs: Leasing requires minimal initial outlay, preserving cash for other business needs.

2. Flexibility: Leases can be structured to accommodate changing production needs, and you can upgrade to newer models more easily[3].

3. Tax Benefits: Lease payments can be fully deductible as operating expenses[4].

Disadvantages of Leasing

1. No Ownership: At the end of the lease, you do not own the equipment unless a purchase option is exercised.

2. Long-term Costs: Leasing can be more expensive over time if the lease is continuously renewed[5].

Leasing Options

Leasing options vary, but most agreements involve a fixed monthly payment for a set period, typically between 6 months and 3 years[8]. At the end of the lease, you may have the option to extend the lease, return the equipment, or purchase it at a discounted price.

Choosing the Right Option

The decision to buy or lease plastic extrusion equipment depends on your company's financial situation, production needs, and strategic goals. If you have stable production requirements and the financial resources to cover the initial cost, buying might be the better option. However, if you need flexibility and want to preserve cash flow, leasing could be more beneficial.

Factors to Consider

1. Financial Resources: Evaluate your company's ability to cover the initial cost of purchasing equipment.

2. Production Needs: Consider whether your production needs are stable or fluctuating.

3. Technological Advancements: Assess how quickly technology in your industry is evolving.

Strategic Planning

When deciding between buying and leasing, it's essential to have a strategic plan in place. This includes forecasting production needs, assessing financial capabilities, and considering the potential for technological advancements.

Additional Considerations

Facility Costs

In addition to equipment costs, consider the costs associated with the facility where the equipment will be housed. Leasing a facility can provide flexibility and lower upfront costs, similar to leasing equipment[2]. However, purchasing a facility can offer long-term savings and asset ownership.

Utility and Maintenance Costs

Both leasing and purchasing require consideration of ongoing utility and maintenance costs. Leasing often shifts maintenance responsibilities to the lessor, while purchasing requires you to handle these costs directly[4].

Environmental Impact

Plastic extrusion is generally efficient and reduces waste, but consider the environmental impact of your operations. Leasing can help reduce disposal costs by allowing for easier upgrades to more environmentally friendly technologies[7].

Case Studies

Example of Leasing Success

A company in the medical sector successfully expanded its production capacity by leasing extrusion equipment. This allowed them to diversify their product range without significant upfront investments, ensuring flexibility and financial stability[7].

Example of Buying Success

Another company, with stable production needs, opted to purchase their extrusion equipment. Over time, they benefited from cost savings and the ability to customize the equipment to meet specific production requirements.

Conclusion

Deciding whether to buy or lease plastic extrusion equipment is a critical business decision that impacts your factory's operations and financial health. Both options have their advantages and disadvantages, and the right choice depends on your specific circumstances. By carefully evaluating your financial situation, production needs, and strategic goals, you can make an informed decision that supports your business growth.

Frequently Asked Questions

1. What are the primary benefits of leasing plastic extrusion equipment?

Leasing offers lower initial costs, flexibility in upgrading equipment, and tax benefits. It allows companies to acquire plastic extrusion equipment without a significant upfront investment.

2. How does buying plastic extrusion equipment compare to leasing in terms of long-term costs?

Buying can be more cost-effective in the long run if the equipment is used for an extended period. However, leasing might be more expensive over time if the lease is continuously renewed.

3. What factors should I consider when choosing between buying and leasing plastic extrusion equipment?

Key factors include financial resources, production needs, technological advancements, and strategic business goals.

4. Can leasing help companies stay up-to-date with the latest technology in plastic extrusion?

Yes, leasing allows companies to upgrade to newer models more easily, helping them stay current with technological advancements.

5. Are there any tax advantages to leasing plastic extrusion equipment?

Yes, lease payments can be fully deductible as operating expenses, which can provide significant tax benefits.

Citations:

[1] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[2] https://businessplan-templates.com/blogs/startup-costs/pvc-extrusion-plant

[3] https://polymer-process.com/what-does-the-average-plastic-extrusion-line-cost/

[4] https://www.swiftpak.co.uk/insights/leasing-v-purchasing-machinery

[5] https://bizfund.ca/2024/05/equipment-leasing-vs-purchasing-a-comprehensive-comparison/

[6] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[7] https://www.bausano.com/en/press-and-news/maximising-production-capacity-with-a-minimal-investment

[8] https://plastiwin.com/uncategorized/how-to-buy-plastic-extrusion-equipment/

[9] https://www.bausano.com/en/press-and-news/how-to-decide-between-new-and-used-equipment

[10] https://newfrontierfunding.com/leasing-vs-purchasing-equipment/

[11] https://www.bdc.ca/en/articles-tools/money-finance/get-financing/buy-lease-business-equipment

[12] https://www.icarus-fund.com/plastics-equipment-financing-unlock-capital/

[13] https://www.linkedin.com/pulse/analysis-machine-cost-models-purchase-vs-lease-oluoch-odhiambo-lt1lf

[14] https://www.plasticstoday.com/plastics-processing/words-of-wisdom-buying-equipment-price-vs-productivity

[15] https://www.wolterskluwer.com/en/expert-insights/case-study-equipment-leasing-vs-purchasing

[16] https://www.boyuextruder.com/Blog/5-advantages-plastic-extrusion.html

[17] https://www.ptonline.com/blog/post/new-lease-accounting-rules-is-your-plastics-processing-business-ready

[18] https://pl-mach.com/how-to-conduct-a-cost-analysis-for-a-plastic-extruder-machine-a-step-by-step-guide/

[19] https://www.recyclingtoday.com/article/birch-plastics-toll-processing/

[20] https://kettleconsulting.co.za/deciding-whether-to-buy-or-lease-equipment/