Content Menu

● Introduction to Extruders

>> Aluminum Alloy Extruders

>>> Aluminum Extrusion Process:

>> BMG Extruders

>>> Bondtech BMG Extruder Features:

● Durability Comparison

>> Aluminum Alloy Extruders

>> BMG Extruders

● Extruder Aluminum Alloy vs BMG

>> Applications

● Detailed Analysis of Aluminum Extrusion

>> Advantages of Aluminum Extrusion

>> Applications of Aluminum Extrusion

● Detailed Analysis of BMG Extruders

>> Features of Bondtech BMG Extruders

>> Applications of BMG Extruders

● Comparison of Durability and Performance

● Conclusion

● FAQs

>> 1. What are the primary advantages of using aluminum alloy extruders?

>> 2. How does the Bondtech BMG extruder enhance 3D printing performance?

>> 3. Can BMG extruders be used with different types of filaments?

>> 4. What is the significance of the gearing ratio in the Bondtech BMG extruder?

>> 5. How do aluminum alloy extruders contribute to sustainability?

● Citations:

When comparing the durability of aluminum alloy extruders and BMG extruders, it's essential to understand the unique characteristics and applications of each. Aluminum alloy extruders are commonly used in various industries for their strength, corrosion resistance, and thermal conductivity, while BMG extruders, particularly those like the Bondtech BMG, are renowned for their precision and reliability in 3D printing applications.

Introduction to Extruders

Extruders are critical components in both industrial extrusion processes and 3D printing. They are responsible for pushing material through a die to create specific shapes or profiles. In industrial settings, aluminum alloy extruders are widely used for producing complex profiles due to their durability and versatility. In contrast, BMG extruders, such as those used in 3D printing, focus on precision and material handling.

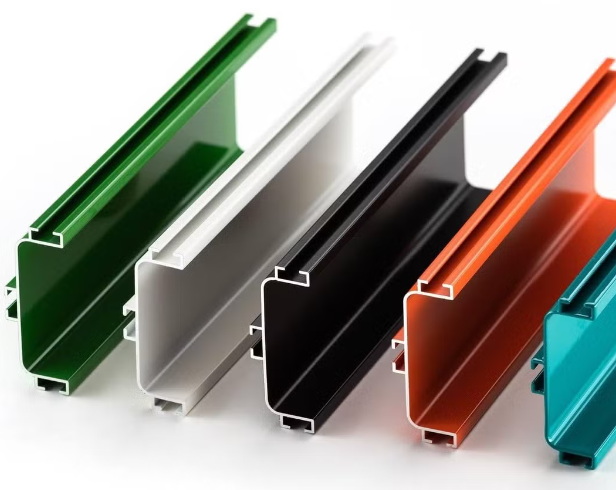

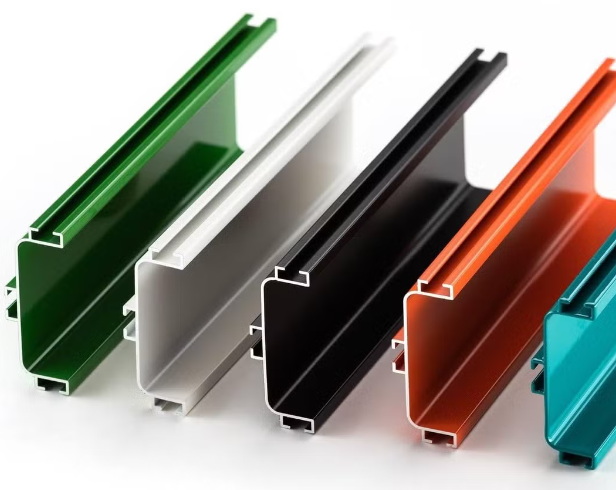

Aluminum Alloy Extruders

Aluminum alloy extruders are favored for their ability to withstand high pressures and temperatures, making them ideal for applications like aluminum extrusion, where complex shapes are required. The process involves pushing aluminum billets through a die to form desired profiles, which are lightweight, strong, and corrosion-resistant.

Aluminum Extrusion Process:

1. Material Preparation: Aluminum billets are prepared for extrusion.

2. Heating: Billets are heated to a high temperature.

3. Extrusion: The heated billet is pushed through a die to form the desired shape.

4. Cooling and Stretching: The extruded profile is cooled and stretched to achieve the final dimensions.

BMG Extruders

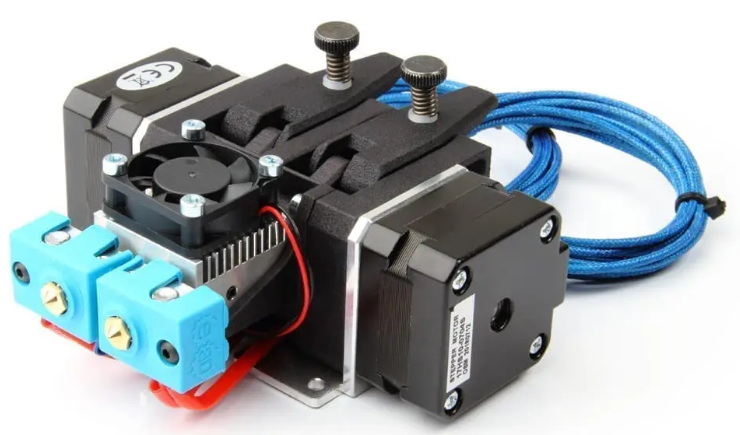

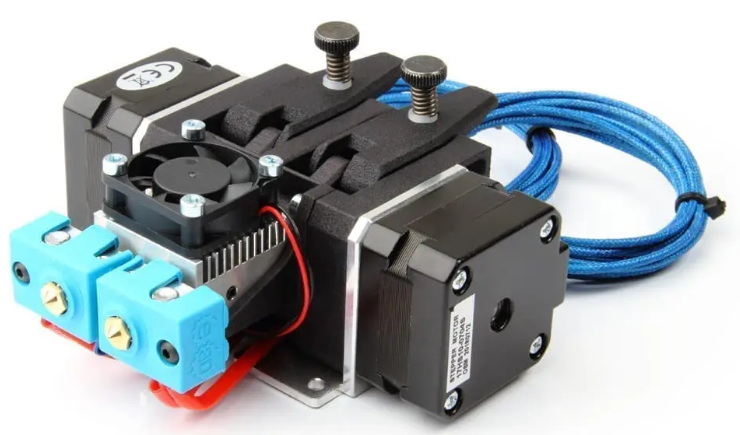

BMG extruders, particularly those designed by Bondtech, are known for their use in 3D printing. These extruders utilize Dual-Drive technology to ensure consistent filament feeding, making them highly reliable for printing with various materials.

Bondtech BMG Extruder Features:

- Dual-Drive Technology: Ensures constant grip on the filament.

- Adjustable Tension: Allows for fine-tuning based on material type.

- Quick Release: Facilitates easy filament changes.

- Multi-Material Capability: Handles a wide range of filaments.

Durability Comparison

Aluminum Alloy Extruders

Aluminum alloy extruders are inherently durable due to the properties of aluminum itself. Aluminum is lightweight, strong, and resistant to corrosion, making it ideal for applications where these characteristics are beneficial. The extrusion process allows for the creation of complex shapes with varying wall thicknesses, enhancing strength where needed.

BMG Extruders

BMG extruders, specifically those like the Bondtech BMG, are designed for precision and reliability in 3D printing. While they are durable in their own right, their durability is more about maintaining consistent performance under controlled conditions rather than withstanding extreme pressures or temperatures.

Extruder Aluminum Alloy vs BMG

When comparing extruder aluminum alloy vs BMG, it's crucial to consider the context of use:

- Aluminum Alloy Extruders are better suited for industrial applications requiring high strength and thermal conductivity.

- BMG Extruders excel in precision applications like 3D printing, where consistent material flow is critical.

Applications

- Aluminum Extrusion: Ideal for producing lightweight, strong profiles used in construction, automotive, and aerospace industries.

- 3D Printing: BMG extruders are preferred for their ability to handle a variety of filaments with precision.

Detailed Analysis of Aluminum Extrusion

Aluminum extrusion is a versatile process that offers numerous advantages, including the ability to produce complex shapes efficiently and with minimal material waste. The process is widely used across various industries due to its ability to create lightweight yet strong components.

Advantages of Aluminum Extrusion

- High Strength and Rigidity: Aluminum extrusions exhibit excellent strength and rigidity, making them suitable for applications in building structures and machinery equipment.

- Material Efficiency: The extrusion process ensures high utilization of aluminum materials, reducing material wastage and enhancing cost-effectiveness.

- Lightweight: Products made through aluminum extrusion have lower density compared to other metals, making them widely used in industries such as automotive and aerospace.

- Corrosion Resistance: With proper surface treatment, aluminum extrusion products can enhance their corrosion resistance, prolonging their lifespan.

Applications of Aluminum Extrusion

Aluminum extrusions are used in a wide range of industries, including:

- Automotive Manufacturing: Used in the production of car frames, engine components, doors, etc., lightweight design helps improve fuel efficiency in vehicles.

- Construction and Building Materials: Utilized for manufacturing window frames, door frames, bridge structures, etc., offering excellent load-bearing capacity and weather resistance.

- Aerospace: Extruded aluminum is used for aircraft fuselage frames and other structural elements, providing the strength needed for high-performance applications at a lower weight.

- Electronics: Aluminum extrusions are commonly used in heat sinks to dissipate heat generated by electronic components, prolonging their lifespan and ensuring efficiency.

Detailed Analysis of BMG Extruders

BMG extruders, particularly those designed by Bondtech, are renowned for their precision and reliability in 3D printing applications. These extruders utilize Dual-Drive technology to ensure consistent filament feeding, making them highly reliable for printing with various materials.

Features of Bondtech BMG Extruders

- Dual-Drive Technology: Ensures constant grip on the filament, reducing the risk of grinding or slipping.

- Adjustable Tension: Allows for fine-tuning based on material type, ensuring optimal performance with different filaments.

- Quick Release: Facilitates easy filament changes, making it convenient to switch between different materials.

- Multi-Material Capability: Handles a wide range of filaments, from nylons and TPU/TPE to rigid carbon-filled materials.

Applications of BMG Extruders

BMG extruders are primarily used in 3D printing applications where precision and consistent material flow are critical. They are suitable for both Bowden and Direct Drive setups, offering flexibility in printer configurations.

Comparison of Durability and Performance

When comparing the durability and performance of aluminum alloy extruders and BMG extruders, it's essential to consider the specific requirements of the application:

- Aluminum Alloy Extruders are more durable in terms of withstanding high pressures and temperatures, making them ideal for industrial applications.

- BMG Extruders offer precision and reliability in controlled environments like 3D printing, where consistent filament feeding is crucial.

Conclusion

In conclusion, while both aluminum alloy extruders and BMG extruders have their strengths, they serve different purposes. Aluminum alloy extruders are more durable in terms of withstanding high pressures and temperatures, making them ideal for industrial applications. BMG extruders, on the other hand, offer precision and reliability in controlled environments like 3D printing. The choice between the two depends on the specific requirements of the application.

FAQs

1. What are the primary advantages of using aluminum alloy extruders?

Aluminum alloy extruders offer advantages such as high strength, corrosion resistance, and thermal conductivity, making them suitable for applications requiring these properties.

2. How does the Bondtech BMG extruder enhance 3D printing performance?

The Bondtech BMG extruder enhances 3D printing performance through its Dual-Drive technology, which ensures consistent filament feeding and reduces the risk of filament grinding or slipping.

3. Can BMG extruders be used with different types of filaments?

Yes, BMG extruders are designed to handle a wide range of filaments, from nylons and TPU/TPE to rigid carbon-filled materials.

4. What is the significance of the gearing ratio in the Bondtech BMG extruder?

The 3:1 gearing ratio in the Bondtech BMG extruder provides unparalleled pushing power and fast retractions, making it suitable for both high-resolution prints with small nozzles and high-flow prints with large nozzles.

5. How do aluminum alloy extruders contribute to sustainability?

Aluminum alloy extruders contribute to sustainability through the recyclability of aluminum, which can be recycled infinitely without losing its properties, reducing waste and environmental impact.

Citations:

[1] https://www.unisontek.com.tw/?%2C152

[2] https://www.matterhackers.com/store/l/bondtech-bmg-extruder/sk/M88WAUL2

[3] https://3dprintbeginner.com/all-metal-bmg/

[4] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[5] https://www.bondtech.se/product/bmg-extruder/

[6] https://hitopindustrial.com/aluminum-extrusion-process/

[7] https://top3dshop.com/product/bondtech-bmg-extruder

[8] https://kimsen.vn/uses-of-aluminum-extrusion-ne37.html

[9] https://electrobes.com/product/dual-drive-bmg-bowden-extruder-1-75mm-high-performance-upgrading-parts-for-3d-printer/

[10] https://asaluminum.com/blog/exploring-the-art-of-aluminum-extrusion-methods-advantages-and-applications/

[11] https://www.3djake.com/bondtech/extruder-bmg-right

[12] https://www.linkedin.com/pulse/analysis-aluminum-alloy-3d-printing-industry

[13] https://aec.org/industrial

[14] https://www.tronxy3dprinter.com/en-mx/products/tronxy-3d-printing-bmg-extruder-kit-for-3d-printer-36-metor-version

[15] https://haluminium.com/Product/aluminum-extrusion-molding/

[16] https://www.3dware.ch/en/accessories/hotend-extruder/bondtech-01900210-1-bondtech-bmg-extruder-1-75mm-standard-righthand

[17] https://www.reddit.com/r/3Dprinting/comments/bjlpqm/aluminum_bmg_extruder_variants/

[18] https://www.gabrian.com/aluminium-extrusions/industries/

[19] https://evelta.com/bmg-black-dual-gear-extruder-for-3d-printers/

[20] https://www.cnckitchen.com/blog/which-is-the-strongest-3d-printing-extruder