Content Menu

● Understanding Aluminum Extrusion

● Planning Your Aluminum Extrusion Plant

>> Site Selection and Infrastructure

>> Budget Considerations

● Essential Aluminum Extrusion Plant Machinery

>> 1. Billet Preparation Workshop

>> 2. Extrusion Workshop

>> 3. Finishing Workshop

● Selecting the Right Machinery

>> Key Factors

>> Machinery Comparison

● Production Line Setup

>> Step-by-Step Process

● Quality Control and Certification

● Operational Best Practices

● Conclusion

● FAQs

>> 1. What is the minimum budget for a small-scale extrusion plant?

>> 2. How long do extrusion dies typically last?

>> 3. Can I use second-hand extrusion machinery?

>> 4. What surface finishes are available for extruded profiles?

>> 5. How do I calculate required press tonnage?

● Citations:

Aluminum extrusion is a cornerstone of modern manufacturing, enabling the creation of complex profiles for industries ranging from construction to aerospace. Establishing an extrusion plant requires strategic planning, precise machinery selection, and adherence to quality standards. This guide provides a comprehensive roadmap for setting up a production facility optimized for efficiency and scalability, with a focus on selecting the right aluminum extrusion plant machinery.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum billets through a die to create continuous shapes. The process includes six key stages[2]:

1. Billet Heating: Preheating aluminum logs to 400–500°C.

2. Extrusion Pressing: Applying up to 15,000 tons of hydraulic pressure to push the billet through the die.

3. Quenching: Rapid cooling to preserve mechanical properties.

4. Stretching and Cutting: Aligning and sizing profiles.

5. Aging: Heat treatment to enhance strength.

6. Surface Finishing: Anodizing, painting, or electrophoresis.

Planning Your Aluminum Extrusion Plant

Site Selection and Infrastructure

- Space Requirements: A minimum of 10,000 sq. meters for machinery, raw material storage, and finished goods.

- Utilities: High-capacity power supply (3-phase), water recycling systems, and gas pipelines.

- Permits: Environmental clearances, fire safety certifications, and industrial zoning approvals[1].

Budget Considerations

Startup costs typically range from $5M to $20M, depending on scale. Major expenses include:

| Cost Component | Percentage of Budget |

| Machinery | 40–50% |

| Facility Construction | 20–30% |

| Labor and Training | 15–20% |

| Permits and Insurance | 5–10% |

Essential Aluminum Extrusion Plant Machinery

A fully equipped plant requires machinery across three workshops:

1. Billet Preparation Workshop

- Aluminum Melting Furnace: For recycling scrap or processing raw ingots.

- Homogenizing Furnace: Ensures uniform billet microstructure.

- Billet Cutting Machine: Cuts logs into 6–12 meter lengths[5].

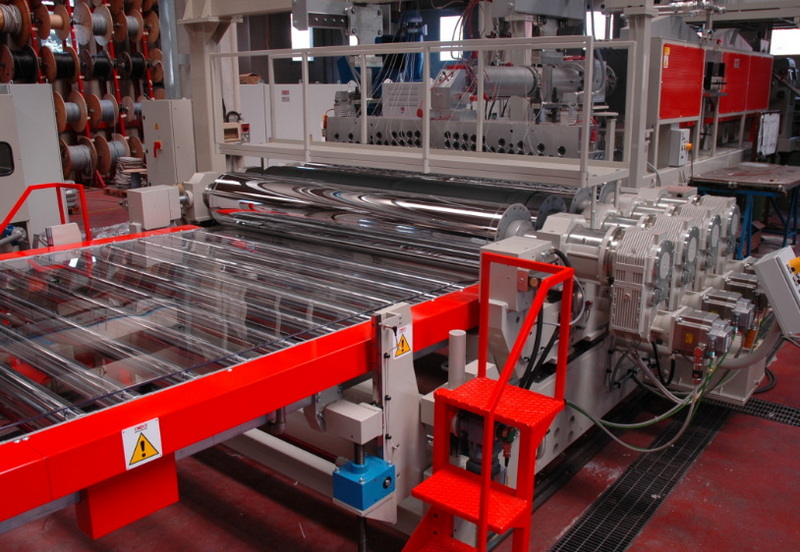

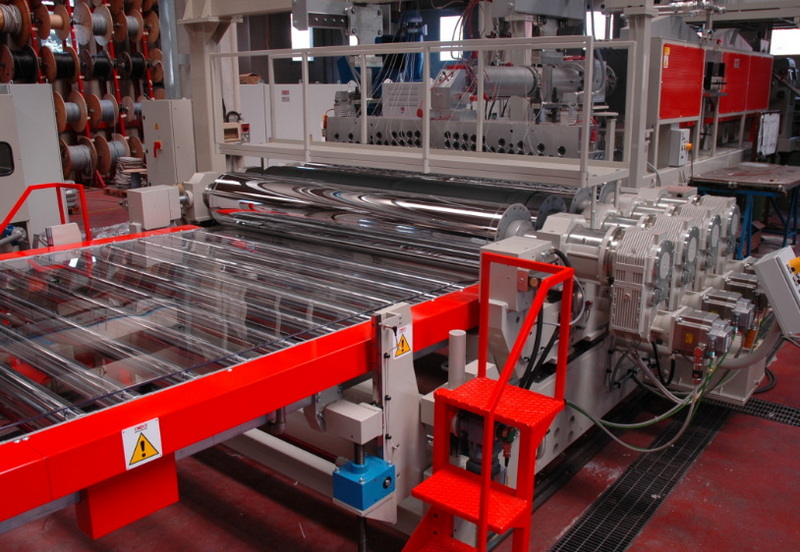

2. Extrusion Workshop

- Extrusion Press: The core machine, available in 1,800–10,000-ton capacities. Horizontal presses are ideal for high-volume production.

- Mold Heating Oven: Preheats dies to 450–500°C to prevent thermal shock.

- Puller Machine: Automates profile handling, reducing labor costs and defects[5].

3. Finishing Workshop

- Anodizing Tanks: Electrochemical surface treatment for corrosion resistance.

- Electrophoresis Coating Line: Applies uniform paint layers.

- CNC Machining Centers: For precision cutting and drilling[4].

Selecting the Right Machinery

Key Factors

1. Tonnage: Match press capacity to profile cross-sectional area. For example:

- 1,800-ton press: Profiles up to 200 mm wide.

- 5,000-ton press: Architectural systems like curtain walls.

2. Automation Level: Automated billet loaders and pullers reduce manual errors.

3. Energy Efficiency: Electric presses consume 30% less power than hydraulic models[5].

Machinery Comparison

| Machine Type | Hydraulic Press | Electric Press |

| Speed | 8–12 m/min | 15–25 m/min |

| Energy Use | High | Moderate |

| Maintenance Cost | 15–20% of TCO | 10–15% of TCO |

Production Line Setup

Step-by-Step Process

1. Install Extrusion Press: Anchor to a reinforced concrete foundation (≥2m depth).

2. Integrate Heating Systems: Connect billet and mold ovens to the press.

3. Calibrate Puller and Stretcher: Ensure alignment within ±0.5mm tolerance.

4. Test Run: Extrude 5–10 trial billets to adjust temperature and speed[2].

Quality Control and Certification

- Inspection Tools: Laser micrometers, tensile testers, and spectrophotometers.

- Standards: ISO 9001, ASTM B221 for mechanical properties, and AAMA 611 for architectural finishes[4].

Operational Best Practices

- Staff Training: 200–300 hours of machine operation and safety protocols.

- Preventive Maintenance: Replace hydraulic seals every 6 months, recalibrate sensors quarterly.

- Scrap Management: Use dross processing machines to recycle 95% of waste[5].

Conclusion

Establishing an aluminum extrusion plant demands a strategic blend of advanced machinery, rigorous planning, and skilled labor. By prioritizing high-performance aluminum extrusion plant machinery like automated presses and CNC finishing systems, manufacturers can achieve production efficiencies of 85–90%. Continuous investment in R&D and worker training ensures long-term competitiveness in this $90 billion global market.

FAQs

1. What is the minimum budget for a small-scale extrusion plant?

A compact plant with a 1,800-ton press and basic finishing lines requires ~$5M, excluding land costs[1].

2. How long do extrusion dies typically last?

Dies endure 5–50 runs depending on alloy hardness. Proper tempering and nitrogen cooling can extend lifespan by 40%[4].

3. Can I use second-hand extrusion machinery?

Refurbished presses reduce upfront costs by 30–50%, but may lack automation features and energy efficiency[5].

4. What surface finishes are available for extruded profiles?

Options include mill finish, anodizing (10–25µm thickness), powder coating, and wood-grain electrophoresis[4].

5. How do I calculate required press tonnage?

Use the formula:

Tonnage = Profile Cross-Sectional Area (mm²)

For a 200 mm² profile with a 40:1 ratio, select a 1,800-ton press[5].

Citations:

[1] https://www.outashi.com/blog/setting-up-aluminum-extrusion-factory-cost-guide-id31.html

[2] https://www.rapiddirect.com/blog/aluminum-extrusion-process/

[3] https://www.alamy.com/stock-photo/aluminum-extrusion.html

[4] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[5] https://www.brightstaralu.com/all-information-you-need-to-know-about-aluminium-extrusion-plant-setup/

[6] http://aluminum-solution.com/essential-equipment-for-aluminum.html

[7] https://www.linkedin.com/pulse/precautions-aluminum-extrusion-machine-operators-when-operating-jrxoc

[8] https://extruderpress.com/open-aluminum-extrusion-factory/

[9] https://www.pennex.com/press/the-steps-of-aluminum-extrusion

[10] https://www.shutterstock.com/search/aluminium-extrusion

[11] https://www.istockphoto.com/photos/aluminium-extrusion

[12] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[13] https://stock.adobe.com/search?k=%22aluminium+extrusion%22

[14] https://www.fonnovaluminium.com/faqs

[15] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[16] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/

[17] https://www.machine4aluminium.com/what-equipment-is-needed-to-set-up-an-aluminum-extrusion-factory/

[18] https://waykenrm.com/blogs/aluminum-extrusion/

[19] https://www.linkedin.com/pulse/how-install-use-aluminum-profile-extrusion-press-machine-wonsten

[20] https://www.nomexfelt.com/list-news/industry-news/6-necessary-equipment-for-aluminum-extrusion-plant-construction/

[21] https://www.youtube.com/watch?v=iiGlq7408ME

[22] https://www.fszhelu.com/extrusion-press-machine-product/

[23] https://www.linkedin.com/pulse/aluminum-extrusion-process-10-steps-video-clips-nomexfelt

[24] https://www.alcirclebiz.com/nanjing-teyun-products/15891/aluminum-extrusion-machine