Content Menu

● Understanding Tie Rod Bushings in Aluminum Extrusion Presses

● Signs of Worn Tie Rod Bushings

● Tools and Materials Needed

● Step-by-Step Guide to Replacing Tie Rod Bushings

>> 1. Preparation and Safety Measures

>> 2. Removing Pressure from the Tie Rods

>> 3. Loosening and Removing Tie Rod Nuts

>> 4. Extracting the Tie Rods

>> 5. Accessing and Removing Old Bushings

>> 6. Cleaning and Inspecting

>> 7. Installing New Bushings

>> 8. Reinserting and Securing Tie Rods

>> 9. Tightening Tie Rod Nuts

>> 10. Final Checks and Lubrication

● Maintenance Tips for Prolonging Bushing Life

● Common Challenges and Troubleshooting

● The Importance of Professional Assistance

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. How often should tie rod bushings be replaced in an aluminum extrusion press?

>> 2. Can I replace tie rod bushings without completely disassembling the press?

>> 3. What are the consequences of not replacing worn tie rod bushings?

>> 4. Are there any special considerations for aluminum extrusion press tie rod bushings in high-temperature operations?

>> 5. Can upgrading to better quality tie rod bushings improve press performance?

● Citations:

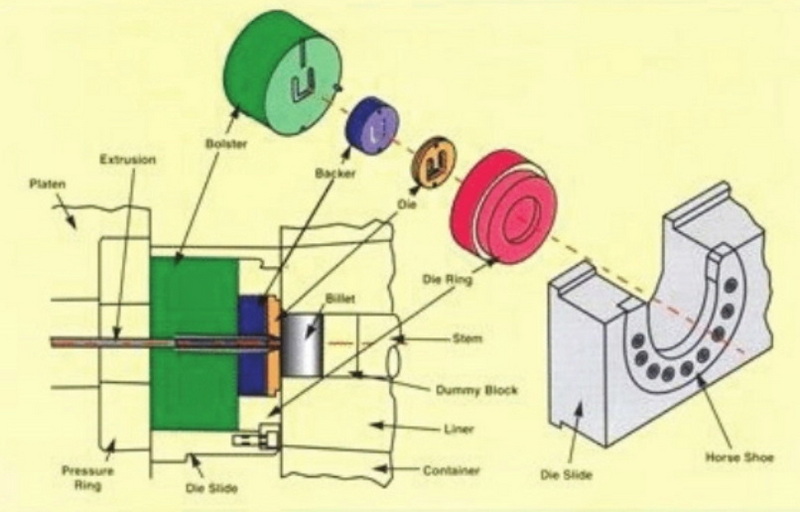

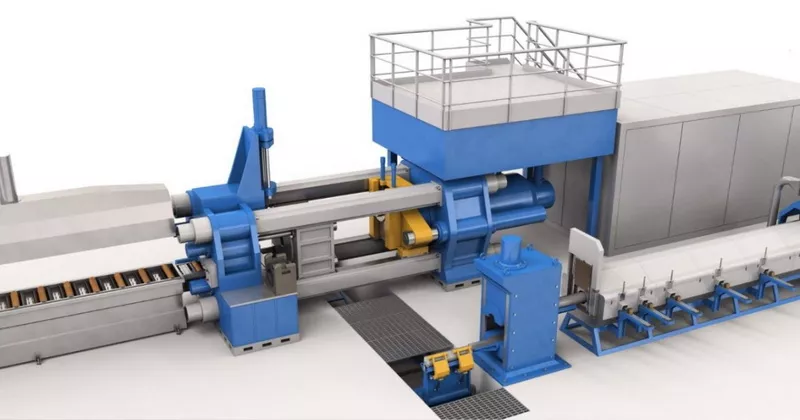

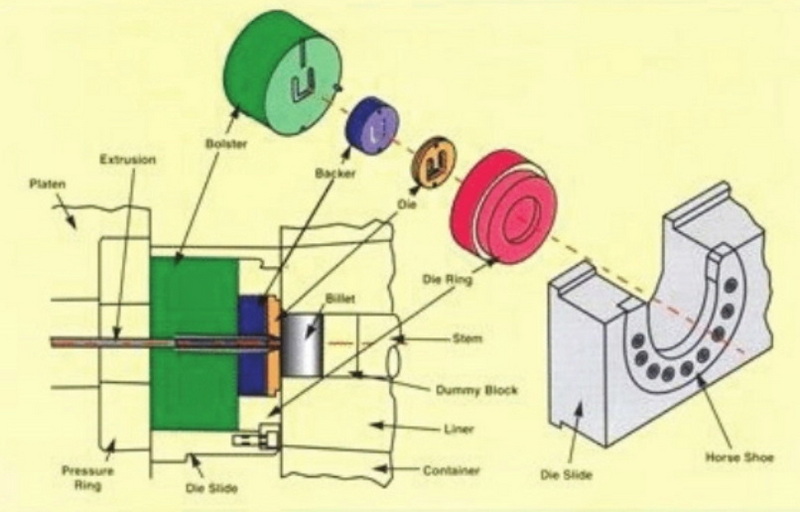

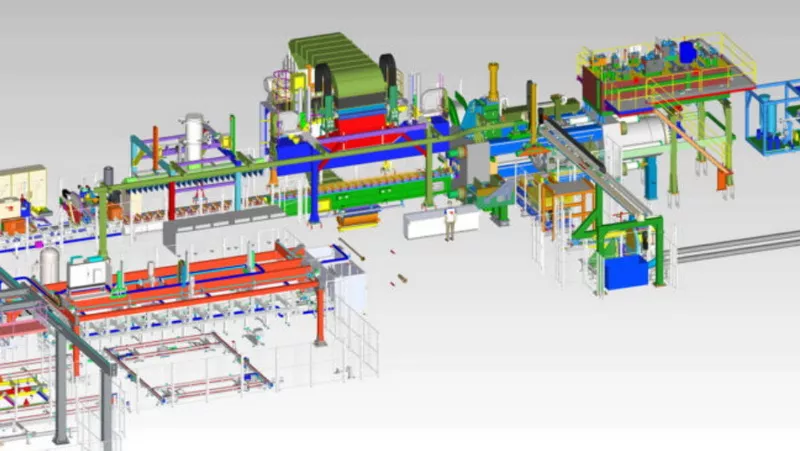

Aluminum extrusion presses are critical machines in the manufacturing industry, relying heavily on components like tie bars, tie rods, and nuts. These parts undergo significant stress during operation and require regular maintenance and occasional replacement. One crucial aspect of this maintenance is replacing worn tie rod bushings, which play a vital role in ensuring the press's alignment and overall performance.[1]

In this comprehensive guide, we'll walk you through the process of replacing worn tie rod bushings in aluminum extrusion presses, providing detailed steps, tips, and best practices to help you maintain your equipment effectively.

Understanding Tie Rod Bushings in Aluminum Extrusion Presses

Before diving into the replacement process, it's essential to understand the role of tie rod bushings in aluminum extrusion presses.

Tie rod bushings are critical components that support the tie bars and rods in extrusion presses. They help maintain proper alignment and reduce friction between moving parts. Over time, these bushings can wear out due to the high pressures and temperatures involved in the extrusion process. When bushings wear, it can lead to misalignment, increased wear on other components, and potentially affect the quality of the extruded products.[1]

Signs of Worn Tie Rod Bushings

Before proceeding with replacement, it's crucial to identify the signs of worn tie rod bushings. Some common indicators include:

1. Increased vibration during operation

2. Misalignment of the press components

3. Visible wear or damage to the bushings

4. Decreased precision in extruded products

5. Unusual noises coming from the tie rod area

Regular inspections are key to catching these issues early. Implementing a well-planned maintenance routine can help prevent unexpected failures and costly downtime.[2]

Tools and Materials Needed

Before starting the replacement process, gather the following tools and materials:

- New tie rod bushings (ensure they match your press specifications)

- Heavy-duty jack or hydraulic lift

- Wrench set

- Socket set

- Torque wrench

- Penetrating oil

- Clean rags

- Safety equipment (gloves, safety glasses, steel-toed boots)

- Grease gun and appropriate lubricant

Step-by-Step Guide to Replacing Tie Rod Bushings

Now, let's dive into the step-by-step process of replacing worn tie rod bushings in your aluminum extrusion press.

1. Preparation and Safety Measures

Before beginning any work, ensure the press is completely shut down and cooled. Implement proper lockout/tagout procedures to prevent accidental startup. Conduct a thorough inspection of the area around the tie rods, noting any additional issues that may need addressing.[2]

2. Removing Pressure from the Tie Rods

Carefully release any residual pressure in the hydraulic system. This step is crucial for safety and to allow for easier removal of the tie rods.

3. Loosening and Removing Tie Rod Nuts

Using the appropriate wrench or socket, begin loosening the tie rod nuts. If they're stubborn due to corrosion, apply penetrating oil and allow it to soak. You may need to use heat in extreme cases, but be cautious not to damage surrounding components.[4]

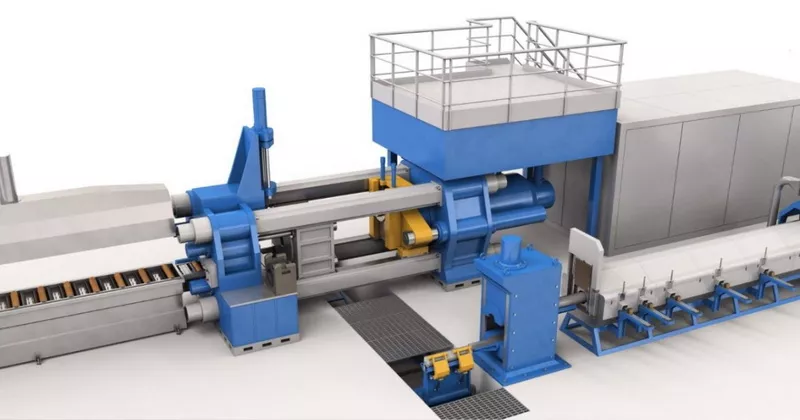

4. Extracting the Tie Rods

Once the nuts are removed, carefully extract the tie rods. This may require a hydraulic puller or press, depending on your specific extrusion press model.

5. Accessing and Removing Old Bushings

With the tie rods removed, you can now access the old bushings. Carefully remove them, noting their orientation and any shims or spacers used.

6. Cleaning and Inspecting

Thoroughly clean the areas where the bushings sit. Inspect for any damage or wear on the surrounding components. This is an excellent opportunity to check for other potential issues that may need addressing.[5]

7. Installing New Bushings

Carefully install the new bushings, ensuring they are seated correctly and aligned properly. If your press uses shims or spacers, replace them in the same configuration as before.

8. Reinserting and Securing Tie Rods

Reinsert the tie rods through the new bushings. Be careful not to damage the new bushings during this process.

9. Tightening Tie Rod Nuts

Replace the tie rod nuts and tighten them to the manufacturer's specified torque. It's crucial to use a torque wrench to ensure proper tightening. Incorrect torque can lead to premature wear or failure.[4]

10. Final Checks and Lubrication

Perform a final inspection of all components. Ensure everything is properly seated and secured. Apply lubricant to the new bushings as per the manufacturer's recommendations.

After installation, it's important to start the press at a low speed and gradually increase it, monitoring for any unusual noises or vibrations.[7]

Maintenance Tips for Prolonging Bushing Life

To maximize the lifespan of your new tie rod bushings and maintain optimal press performance, consider the following maintenance tips:

1. Perform regular inspections: Daily walk-around checks can help identify issues early.[2]

2. Maintain proper alignment: Ensure the press remains correctly aligned to prevent uneven wear on bushings and other components.[2]

3. Lubricate regularly: Keep all moving parts, including bushings, properly lubricated to reduce friction and wear.[2]

4. Schedule predictive maintenance: Use data and regular inspections to predict when components might need replacement, allowing for planned downtime rather than unexpected failures.[2]

5. Monitor operating conditions: Ensure the press is operating within its designed temperature and pressure ranges to prevent premature wear.[5]

Common Challenges and Troubleshooting

During the replacement process, you may encounter some challenges. Here are a few common issues and how to address them:

1. Seized tie rod nuts: Use penetrating oil and heat if necessary. In extreme cases, you may need to cut the nut off and replace it.

2. Misaligned bushings: Ensure proper cleaning and preparation of the bushing seats. Use alignment tools if necessary.

3. Damaged tie rods: If you notice damage to the tie rods during removal, they may need to be replaced along with the bushings.

4. Improper torque: Always use a calibrated torque wrench and follow manufacturer specifications.

5. Post-replacement vibration: This could indicate improper installation or alignment. Double-check all components and consult with a specialist if issues persist.

The Importance of Professional Assistance

While this guide provides a comprehensive overview of the replacement process, it's important to note that working on aluminum extrusion presses requires specialized knowledge and skills. For complex issues or if you're unsure about any step, it's advisable to consult with professional technicians or the press manufacturer. They can provide expert guidance, ensure proper installation, and often offer services like re-squaring and straining your machine using precision strain gauges.[1]

Conclusion

Replacing worn tie rod bushings is a critical maintenance task for aluminum extrusion presses. By following this guide and implementing regular maintenance practices, you can extend the life of your equipment, improve operational efficiency, and maintain the quality of your extruded products. Remember, proper care and timely replacement of components like tie rod bushings not only prevent unexpected downtime but also contribute to the overall longevity and performance of your aluminum extrusion press.

Frequently Asked Questions (FAQ)

1. How often should tie rod bushings be replaced in an aluminum extrusion press?

The frequency of tie rod bushing replacement depends on various factors, including press usage, operating conditions, and maintenance practices. Generally, bushings should be inspected regularly and replaced when signs of wear are evident. Some presses may require bushing replacement every 1-2 years, while others with optimal maintenance might go 3-5 years between replacements.

2. Can I replace tie rod bushings without completely disassembling the press?

In most cases, complete disassembly of the press is not necessary. However, you will need to remove the tie rods to access the bushings. The exact process may vary depending on your specific press model. Always consult your press's manual or a professional technician for guidance.

3. What are the consequences of not replacing worn tie rod bushings?

Neglecting to replace worn tie rod bushings can lead to several issues, including:

- Misalignment of press components

- Increased wear on other parts

- Reduced extrusion quality

- Potential for catastrophic failure

- Increased energy consumption

- Higher maintenance costs in the long run

4. Are there any special considerations for aluminum extrusion press tie rod bushings in high-temperature operations?

Yes, high-temperature operations can accelerate wear on tie rod bushings. In such environments, consider using bushings made from heat-resistant materials. Additionally, more frequent inspections and potentially more regular replacements may be necessary. Ensure proper lubrication suitable for high-temperature applications.

5. Can upgrading to better quality tie rod bushings improve press performance?

Upgrading to higher quality tie rod bushings can indeed improve press performance. Premium bushings often offer:

- Better wear resistance

- Improved load-bearing capacity

- Enhanced heat dissipation

- Reduced friction

- Longer lifespan

Citations:

[1] https://birchmachinery.com/replacement-parts/

[2] https://dunawayinc.com/9-essential-maintenance-tips-to-maximize-the-life-of-your-hydraulic-extrusion-press/

[3] https://www.youtube.com/watch?v=FxHnN9-rzoI

[4] https://www.reddit.com/r/askcarguys/comments/dbje1e/is_a_tie_rod_replacement_something_that_i_a/

[5] https://www.linkedin.com/pulse/nine-main-points-aluminum-extrusion-press-machine-maintenance-

[6] https://www.youtube.com/watch?v=Rep6j3BZRvE

[7] https://www.outashi.com/blog/tips-maintenance-aluminum-extrusion-press-id25.html

[8] https://www.butechbliss.com/our-products/extrusion-forging-equipment/